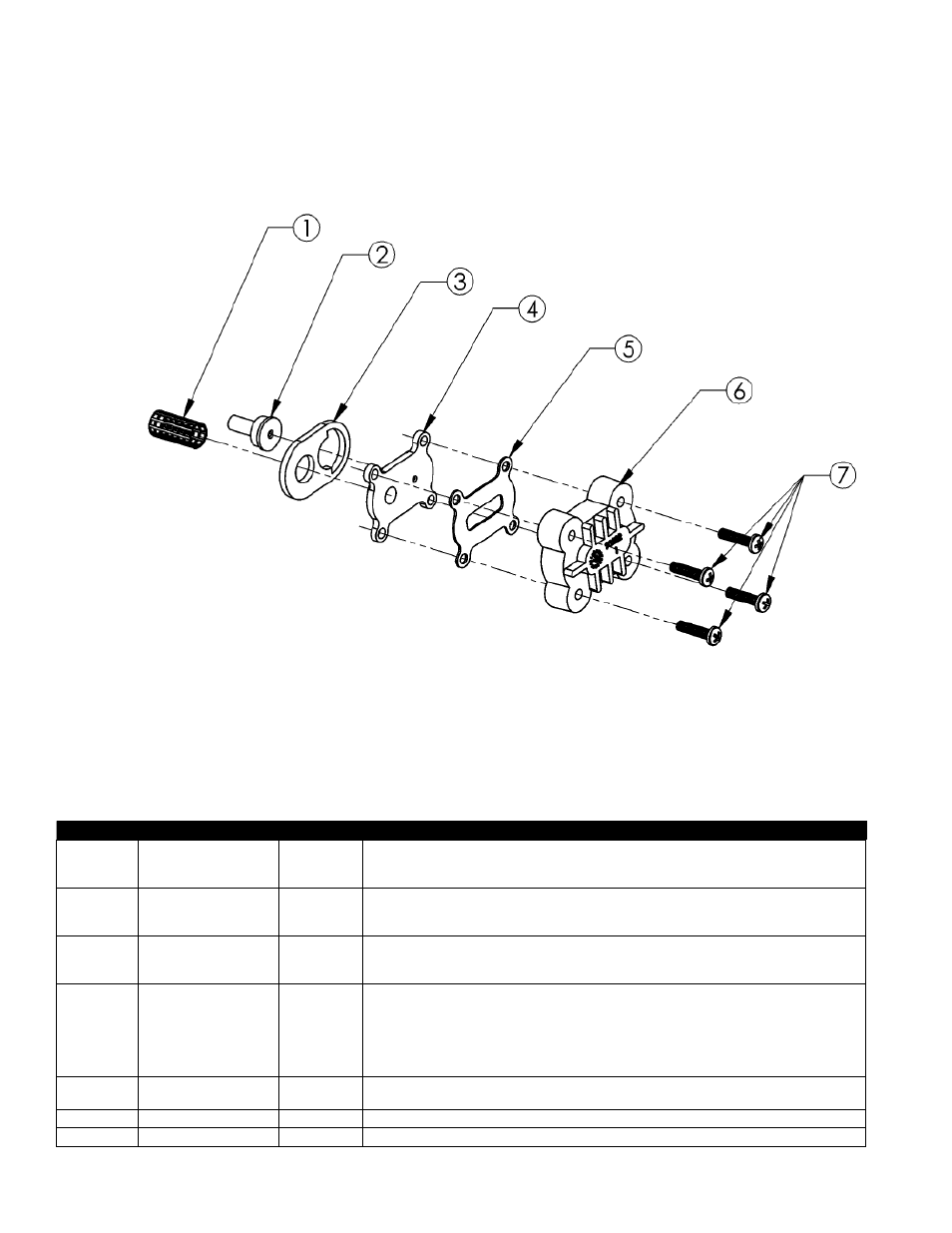

Parts diagrams, Injector assembly – Watts PWSCAB30K User Manual

Page 12

12

Note:

When working on the injector assembly, make sure part #3

aligns properly with the outline marked on part #4.

Item #

Item

QtY.

DescrIptIon

1

Injector Screen

1

Acts as a pre-filter to keep debris from entering the Injector Nozzle and Injector Throat. Attaches to the cylinder on the

Nozzle plate and spherical “bump” inside the Main Valve Body. Some compression of the Screen may occur during

assembly. The openings in the screen must be clear to ensure proper flow to the Injector assembly.

2

Injector Throat

1

Creates the vacuum that draws the brine solution from the brine cabinet in conjunction with the Injector Nozzle (Part #

93221.) The center hole should be clear of debris, round and undamaged. The Injector Throat should be pressed flush

into the opening in the valve. If the Throat needs to be removed, it should be replaced with a new one.

3

Bottom (Thick) Injector Seal

1

Seals between the Injector Nozzle and the Main Valve Body. The gasket has a definite hole pattern that has to match-

up with the Nozzle and Main Valve Body opening. The gasket seals at its outer edges and between the inlet screen

and nozzle opening. These areas must be free of defects such as tears or pits and be free of debris.

4

Injector Nozzle

1

Creates the vacuum that draws the brine solution from the Brine Cabinet in conjunction with the Throat (part #93223).

There are two openings in the Injector Nozzle plate. The small hole, flush on both sides, is the one that creates the

“injection-stream” that enters the Injector Throat. It is very important that this hole be clear of debris, round and

undamaged. If this hole becomes “clogged,” do not use anything to clear this opening that could damage it, such as

metal objects. Use a clean cloth and flush with water. If necessary, a wooden toothpick may be used. When assem-

bling to the Main Valve Body, the Injector Nozzle hole should line up with the Injector Throat.

5

Top (Thin)

Injector Seal

1

Seals between the Injector Nozzle and the Injector Cap. The gasket must be free of defects such as tears or cuts and

be free of debris.

6

Injector Cap

1

Holds the Injector assembly together and seals the assembly to the Main Valve Body.

7

Injector Screw

4

These four machine screws should be tightened evenly and snugly.

Parts Diagrams

Injector Assembly

Figure 13