Iii. valve installation, E. installation considerations, F. drain requirements – Watts PWBWIRON User Manual

Page 5

5

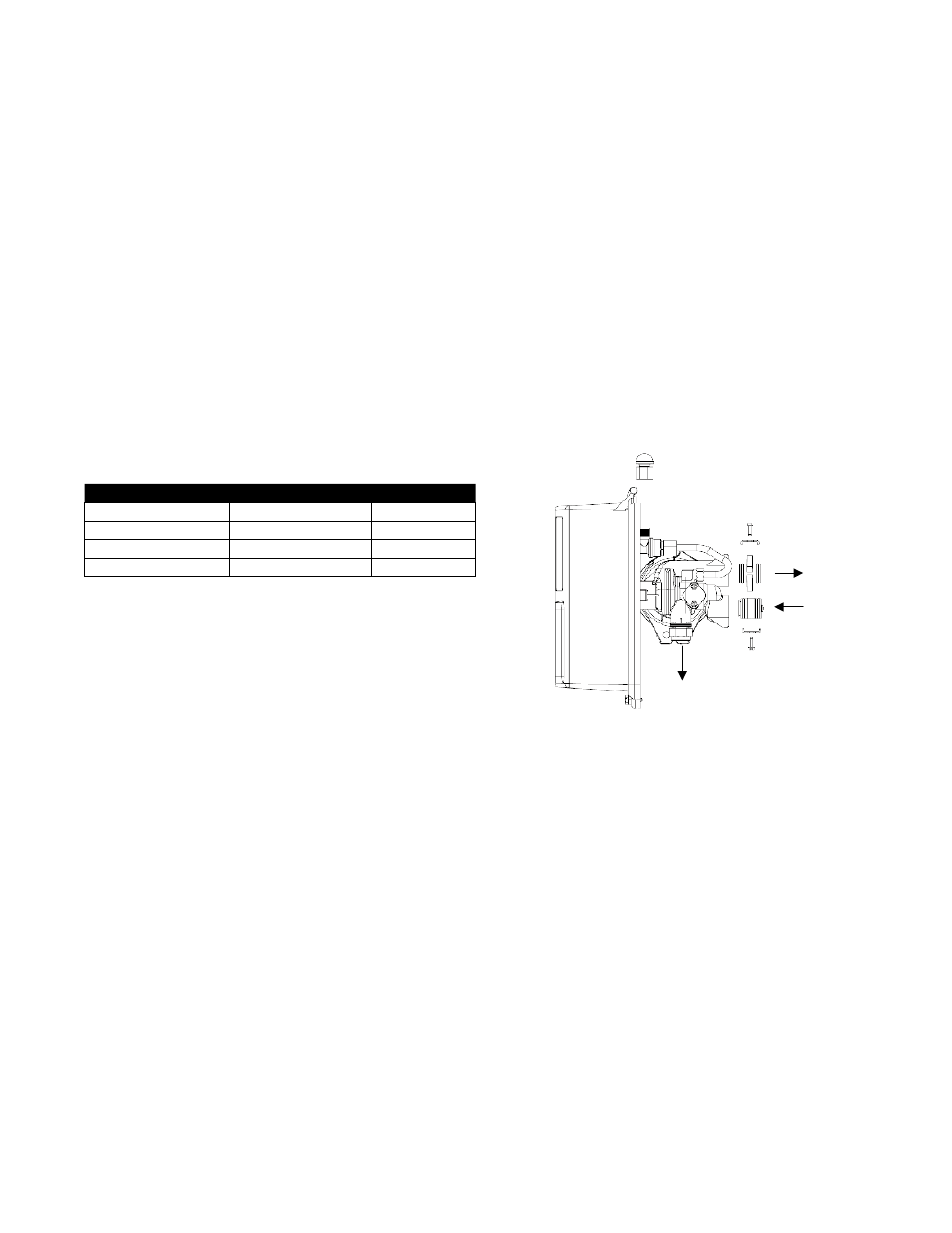

Figure 4

E. Installation Considerations

Consider the following points when determining where to install the

filter:

• Place the system as close as possible to a sewer drain.

• Do not install the filter where it would block access to the water

heater, or access to the main water shutoff, water meter, or electri-

cal panels.

• Install the filter in a place where water damage is least likely to oc-

cur if a leak develops.

• A 120VAC electrical outlet is needed to plug in the transformer.

• Always connect the system to the main water supply pipe before

the water heater.

• Install the system where it will not be subject to temperatures

outside of the limits stated in the Specification Section or to direct

sunlight.

F. Drain Requirements

The drain systems these filters are plumbed into must be able to

accept the drain rates listed below. The well or water supply must

be capable of maintaining a 30 psi minimum feed water pressure,

continuously, at these drain flow rates.

MoDEl

TAnK sIzE

DrAIn rATE

PWBWIRON1

9" x 48", 1 cubic ft.

7 gpm

PWBWIRON15

10" x 54", 1.5 cubic ft.

8 gpm

PWBWIRON2

12" x 52", 2 cubic ft.

12 gpm

PWBWIRON3

13" x 65", 3 cubic ft.

15 gpm

III. Valve Installation

1. Turn off gas or electric supply to the water heater.

2. Close the feed water valve to the plumbing system. Then

relieve the pressure in the plumbing by opening the hot and

cold water faucets.

3. Cut the pipes at the installation point. Use a drain pan to catch

any spillage that results.

4. Move the filter system into installation position.

• Be sure the installation point is downstream of the bladder tank

and irrigation system if this system is being installed on a well.

• The installation surface must be strong enough to support the

weight of the system once it is placed into operation.

5. Plumb INLET and OUTLET connections to and from the filter.

• Be sure the incoming water supply is directed to the INLET port

of the valve.

• The valve body of the control is marked with arrows indicating

the proper flow direction.

• Connections are illustrated below in Figure 4 (shown without

bypass and yoke) and Figure 5 (bypass piping detail).

6. Connect and route the valve drain line using rigid piping or

hose. Use the same size plumbing for the drain line as the fit-

ting provided for the drain connection. The smallest units have

a

1

⁄

2

" connection, the medium sized units have a

3

⁄

4

" connec-

tion, and the largest units have a 1" connection. It is important

to use the same size plumbing as the connection to ensure

proper backwash flow.

Note: Leave an air gap of at least 1

1

⁄

2

" between the end of the

drain plumbing and the drain point.

CAUTION: If making a soldered copper installation, do all

sweat soldering before connecting pipes to the bypass valve.

Torch heat will damage plastic parts.

CAUTION: When turning threaded pipe fittings onto plastic

fittings, use care not to cross-thread or overtighten.

CAUTION: Use PTFE tape on all external pipe threads. Do not

use pipe joint compound.

CAUTION: Support inlet and outlet plumbing in some manner

(use pipe hangers) to keep the weight off of the control valve

drain, bypass, and plumbing yoke points of connection.

Outlet

Inlet

Drain

Drain

Inlet

Outlet