Specifications feed water parameters, Power, Installation – Watts PWBWIRON User Manual

Page 3: Pwbwiron system overview

3

Specifications

Feed Water Parameters

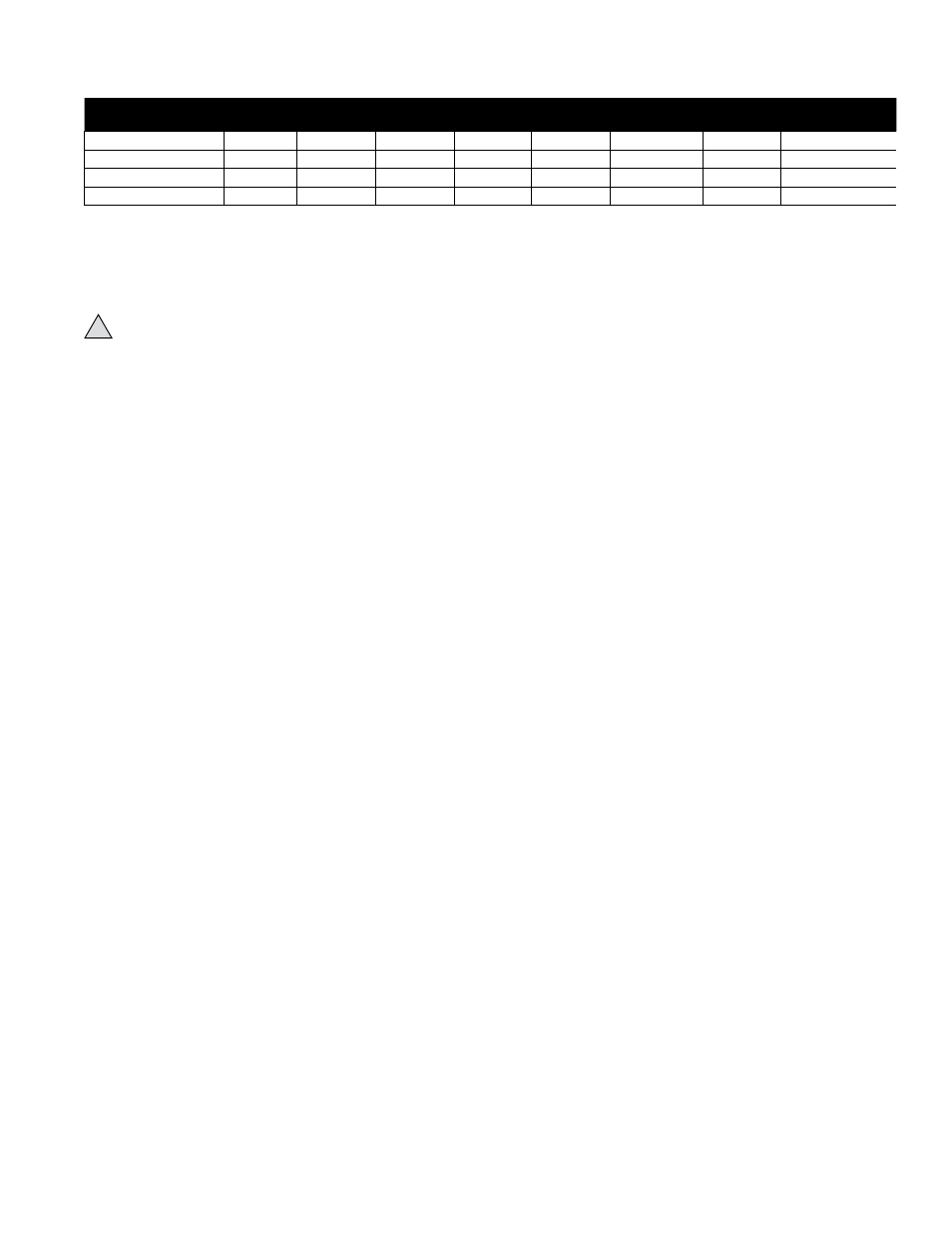

MoDEl

VAlVE

MInErAl TAnK

MEDIA VolUME

GArnET no.12

pEAK sErVIcE

prEssUrE Drop

BAcK WAsH

Floor spAcE rEQUIrED

TYpE

sIzE (DXH)

cUBIc FooT

(lBs)

FloW (GpM)

@pEAK FloW (psI)

FloW (GpM)

(l X W X H)

PWBWIRON1

Time Clock

9" x 48"

1

14

6

<15

7

16" x 15" x 55"

PWBWIRON15

Time Clock

10" x 54"

1.5

14

9

<15

8

16" x 15" x 62"

PWBWIRON2

Time Clock

12" x 52"

2

42

12

<25

12

17" x 15" x 60"

PWBWIRON3

Time Clock

13" x 65"

3

56

18

<25

15

18" x 15" x 74"

Note: Peak service flow rate is for intermittent use only and is not to be interpreted as continuous service flow rate capability. These

systems are designed to treat the domestic water used in a single family dwelling. For irrigation water treatment or higher volume

applications please contact your Watts representative.

Minimum inlet pressure: 30 psig

Maximum operating pressure: 80 psig

Minimum water temperature: 34°F (1°C)

Maximum water temperature: 110°F (43°C)

Maximum iron content: 10 PPM

Maximum manganese content: 5 PPM

Maximum hydrogen sulfide content: 3 PPM

Effective pH range: 6-9

Location: Indoors (Protect from direct sunlight)

Minimum ambient temperature: 34°F (1°C)

Maximum ambient temperature: 122°F (50°C)

Power

Voltage: 120VAC

Frequency: 60Hz

Installation

Location: Indoors (Protect from direct sunlight)

!

Do not use this system on water that is microbiologically

unsafe or of unknown quality without adequate disinfection

before or after the system!

PWBWIRON System Overview

PWBWIRON systems are selected for use when the concentra-

tion of iron, manganese, and hydrogen sulfide in water need to be

reduced. They use the model 2510 AIO Control Valve to reduce the

contaminants in the water without the use of chemicals. The 2510

AIO valve is specially designed to capture a volume of air inside the

system’s mineral tank. Water passes through the AIO valve then

passes through the air head in the top of the mineral tank. Oxygen

from the captured air transfers into the water. The oxygen oxidizes

these contaminates in the water to oxides or solid precipitants. Then

they are mechanically filtered out of the water by the Filox

®

media

filter bed. The Filox

®

media removes any residual iron, manganese,

and hydrogen sulfide that has not formed into a solid by catalyzing it

quickly into an oxide. After a preprogrammed number of days have

passed, the system will perform a regeneration cycle to clean the

Filox

®

media of the solids it has accumulated, draw in more air, rinse,

then return to service. Watts recommends a daily regeneration of the

system. A regeneration every other day may be possible if system

inlet water quality permits (please contact your Watts representative).

Regeneration is as follows:

Backwash (BW): The Backwash cycle washes oxidized contamin-

Cycle Step #1

ates to drain and reclassifies the media bed.

Air Draw (BD):

Air Draw empties water from the tank and replen-

Cycle Step #2

ishes the oxygen within the mineral tank.

Rapid Rinse (RR): Rapid Rinse purges excess atmosphere from the

Cycle Step #3

mineral tank and distributor.

Upon completion of Rapid Rinse the system returns to the service

position.

NOTE: Due to the presence of air in the media tank the maxi-

mum operating pressure of the system is 80 psi.