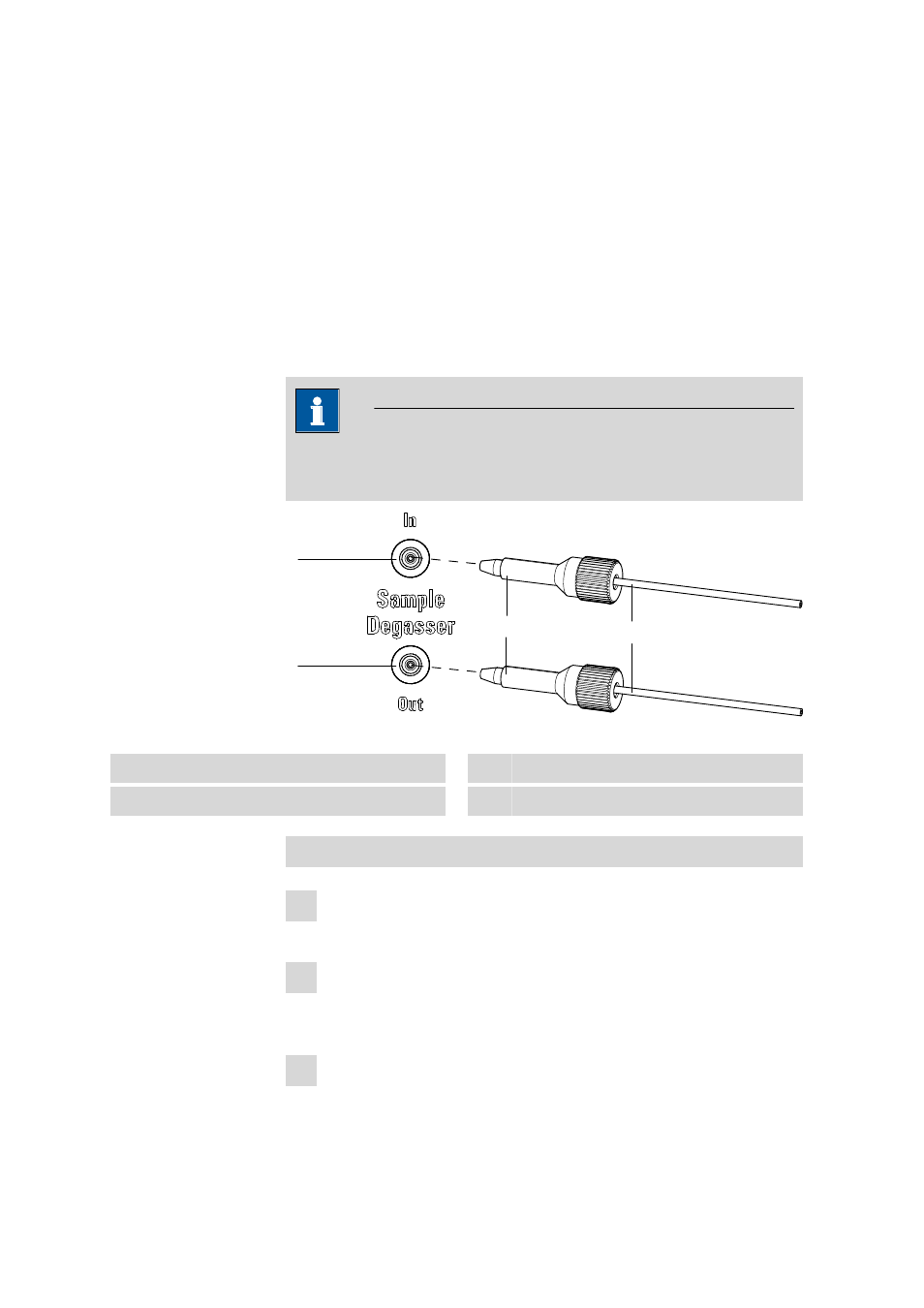

13 sample degasser, Figure 22, Sample degasser – Metrohm 850 Professional IC AnCat User Manual

Page 50: See chapter 2.13 . use optional, See chapter 2.13

2.13 Sample degasser

■■■■■■■■■■■■■■■■■■■■■■

40

■■■■■■■■

850 Professional IC – AnCat

2.13

Sample degasser

The sample degasser removes gas bubbles and disolved gases from the

sample. For degassing, the sample flows into a vacuum chamber through

a special fluoropolymer capillary.

Gas bubbles in the sample lead to poor reproducibility, as the quantity of

sample in the sample loop would not always be the same. Samples (con-

taining gas) should therefore be degassed before injection. For this the

sample is sucked through a degasser chamber before injection, whereby

any gas bubbles are automatically removed.

Note

When using the sample degasser, the rinsing time extends by at least 2

minutes.

1

2

3

4

Figure 22

Sample degasser

1

Sample degasser input

2

Sample degasser output

3

PEEK pressure screw, long 6.2744.090

4

Connection capillaries 6.1803.040

Connecting the sample degasser

1 Remove and keep 6.2744.220 thread stoppers from the input and

output of the sample degasser.

2 Connect the end of the 6.1803.040 sample aspirating capillary con-

3 Connect 6.1803.040 connection capillary with a long PEEK pressure