7 troubleshooting, 1 problems and their solutions, Problems and their solutions – Metrohm 872 Extension Module IC Pump User Manual

Page 62

7.1 Problems and their solutions

■■■■■■■■■■■■■■■■■■■■■■

54

■■■■■■■■

872 Extension Module IC Pump

7 Troubleshooting

7.1

Problems and their solutions

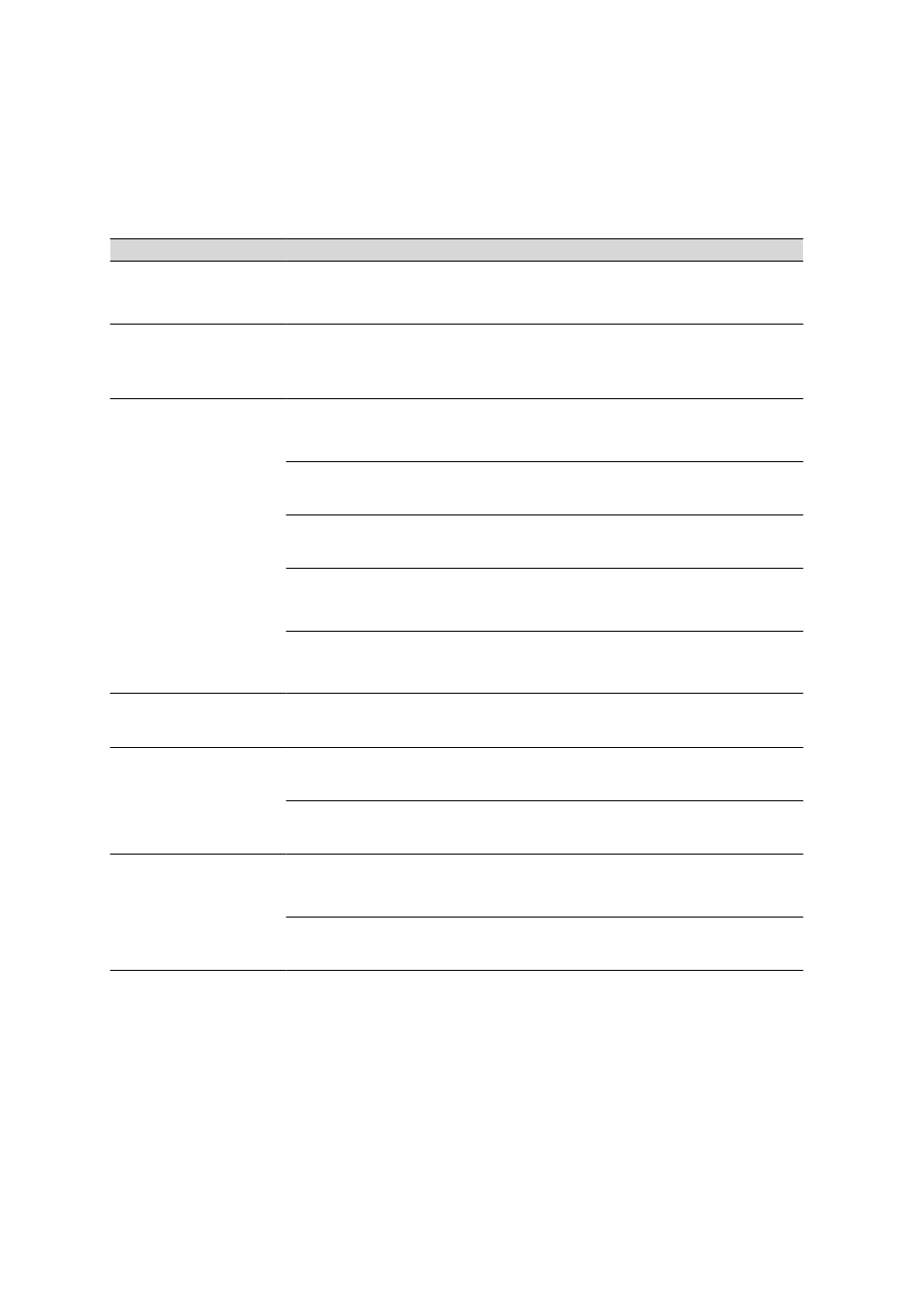

Problem

Cause

Remedy

Marked rise in pres-

sure

6.2821.120 inline filter

blocked.

Replace 6.2821.130 filter (see Chapter 6.5,

page 51).

Drift of the baseline

Eluent – Evaporation of the

organic solvent in the elu-

ent.

Check the eluent bottle attachment (see Figure

16, page 26).

Very noisy baseline

High pressure pump – con-

taminated pump valves.

Clean pump valves (see Chapter 6.4.2, page

41).

Eluent – Leak in the eluent

path.

Check the eluent path.

Eluent – Blockage in the

eluent path.

Check the eluent path.

High pressure pump –

defective piston seals.

Replace piston seals (see Chapter 6.4.2, page

41).

Pulsation damper not con-

nected.

Connect pulsation damper (see Chapter 4.8,

page 35).

Background conduc-

tivity too high

Incorrect eluent.

Change eluent (see Chapter 6.3.2.3, page 40).

Poor reproducibility

of the retention

times

Eluent – Leak in the eluent

path.

Check the eluent path.

Eluent – Blockage in the

eluent path.

Check the eluent path.

Unexpected change

to the retention

times in the chroma-

tograms

Eluent – Gas bubbles in the

eluent.

Check connections of the eluent degasser (see

Chapter 4.5, page 28).

High pressure pump –

defective.

Request Metrohm Service.

Vacuum is not being

built

Eluent Degasser – Connec-

tor Vacuum on the rear of

the instrument not (tightly)

sealed.

■

Seal the connector Vacuum tightly with a

6.144.6040 threaded stopper.

or when using an 872 Extension Module: