Bendix Commercial Vehicle Systems AD-9si Oil Coalescing Air Dryer User Manual

Page 6

6

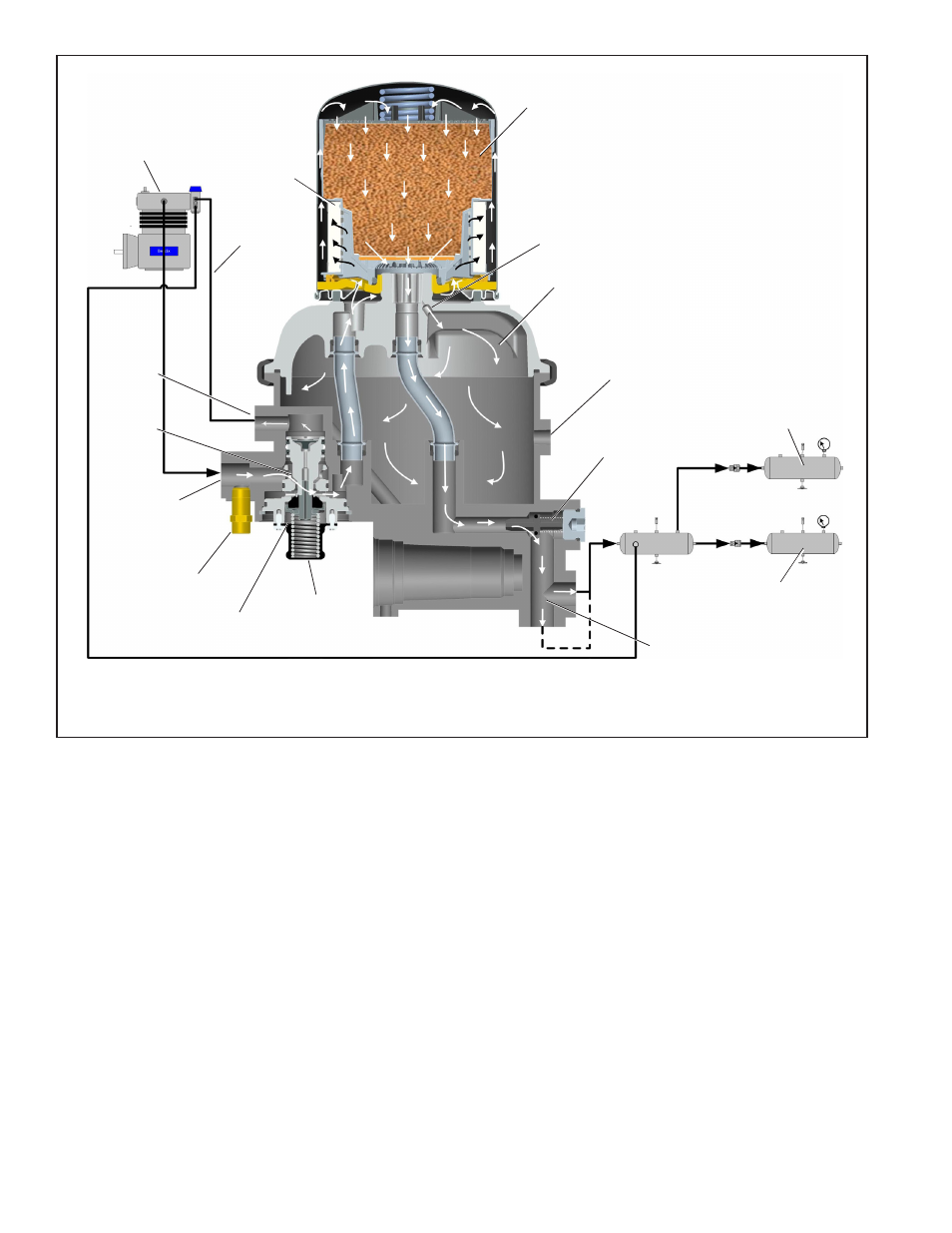

FIGURE 4 -

BENDIX

®

AD-9si

™

AIR DRYER WITHOUT GOVERNOR—CHARGE CYCLE

COMPRESSOR

DESICCANT

BED

DELIVERY

CHECK

VALVE

PURGE

VALVE

TURBO

CUT-OFF

VALVE

(OPEN)

CONTROL

PORT

SUPPLY

PORT

FRONT

RESERVOIR

SAFETY

VALVE

REAR

RESERVOIR

PURGE

ORIFICE

OIL

COALESCING

FILTER

CONTROL

LINE

PURGE AIR

EXTENDED

PURGE

PORT

EXHAUST

DELIVERY

PORT

The actual regeneration of the desiccant drying bed begins

as dry air from the purge volume flows through the purge

orifice into the desiccant bed. Pressurized air from the

purge volume expands after passing through the purge

orifice; its pressure lowers and its volume increases. The

flow of dry air through the drying bed regenerates the

desiccant material by removing any water vapor adhering

to it. Approximately 40 seconds are required for the entire

contents of the purge volume of a Bendix

®

AD-9si

™

air

dryer to flow through the desiccant drying bed. This time

will increase if the dryer is fitted with an extended purge

reservoir.

The delivery check valve assembly prevents air pressure

in the brake system from returning to the air dryer during

the purge cycle. After the purge cycle is complete, the air

dryer is ready for the next charge cycle to begin.