Bendix, Ad-9si, Air dryer removal – Bendix Commercial Vehicle Systems AD-9si Oil Coalescing Air Dryer User Manual

Page 10: Bendix ad-9si air dryer installation, Testing the bendix ad-9si air dryer, Temporary air dryer bypass

10

DO NOT ATTEMPT TO REMOVE THE CLAMP BAND

THAT RETAINS THE TWO HOUSINGS TOGETHER.

SERIOUS INJURY OR DEATH MAY OCCUR IF THESE

INSTRUCTIONS ARE NOT FOLLOWED COMPLETELY.

BENDIX

®

AD-9si

™

AIR DRYER REMOVAL

This air dryer removal process is presented in the event it

becomes necessary to replace the entire air dryer. Normal

service and parts replacement does not require removal

of the air dryer from the vehicle.

1. Park the vehicle on a level surface and prevent

movement by means other than the brakes.

2. Drain all reservoirs to 0 psi.

3. Identify and disconnect the three air lines from the air

dryer housing.

4. Unplug the vehicle wiring harness from the heater and

thermostat assembly connector.

5. Remove the three mounting bolts that secure the air

dryer to the vehicle.

BENDIX AD-9si AIR DRYER INSTALLATION

1. Install the Bendix

®

AD-9si

™

air dryer on the vehicle using

the three existing 1/2"-13 UNC bolts. Torque the bolts

to 720-912 in-lbs. If replacement bolts are necessary

use grade 5 or above and ensure they are the same

length as those originally used to install the dryer. If

the original air dryer is being reinstalled make sure the

threads in the air dryer housing are in good condition.

2. Reconnect the three air lines to the proper ports on the

air dryer—identified during step 3 of the Bendix AD-9si

removal.

3. Reconnect the vehicle wiring harness to the AD-9si

air dryer heater and thermostat assembly connector

by plugging it into the air dryer connector until its lock

tab snaps in place.

4. Before placing the vehicle back into service test the

air dryer operation as indicated in Testing The Bendix

AD-9si

Air Dryer section that follows.

TESTING THE BENDIX AD-9si AIR DRYER

Before placing the vehicle into service, perform the

following tests:

1. Close all reservoir drain valves.

2. Build up system pressure to governor cut-out and note

that the Bendix AD-9si air dryer purges (with an audible

burst of air), followed immediately by approximately 40

seconds of air flowing out of the purge valve.

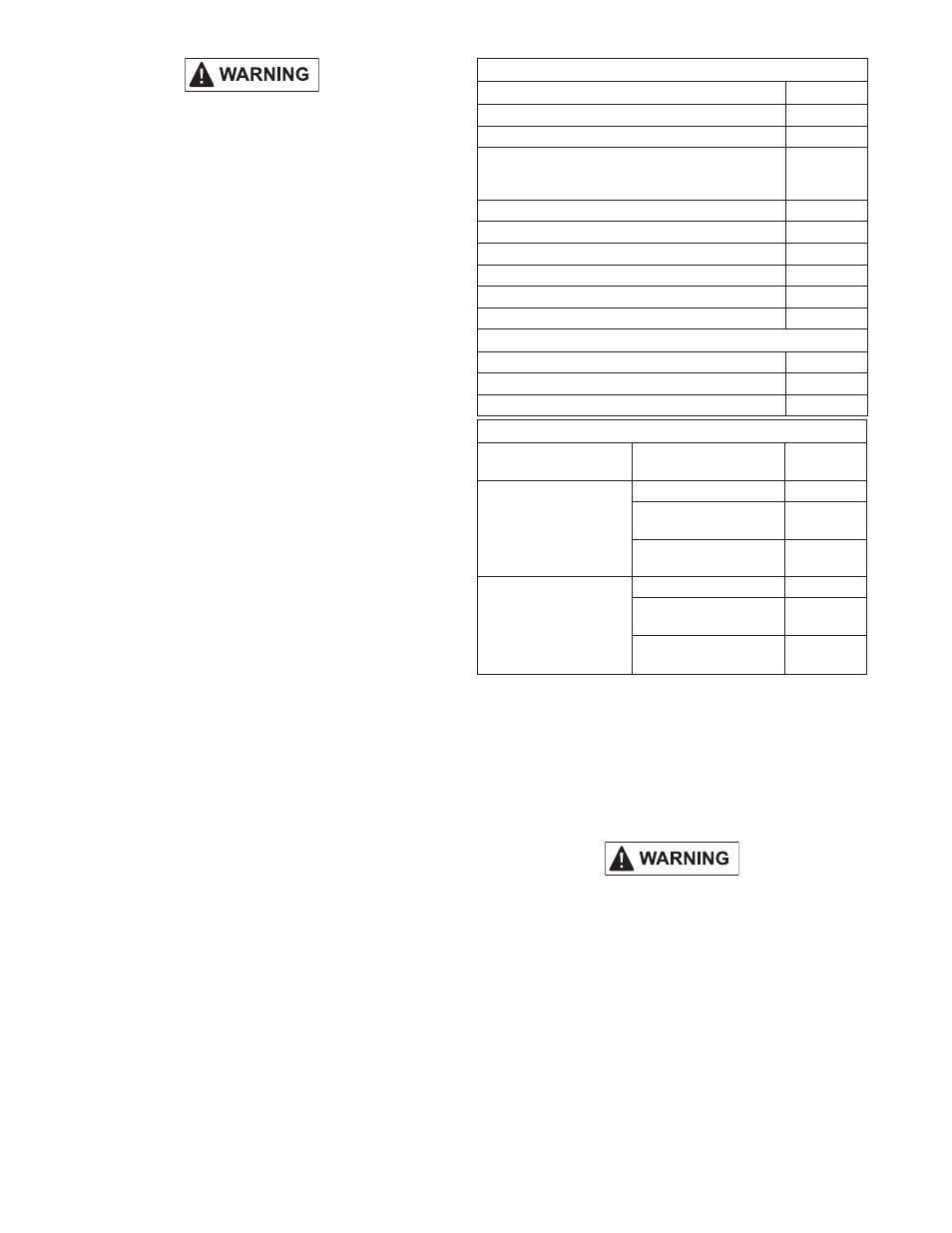

Bendix

®

AD-9si

™

Maintenance Kits

Kit Description

Piece No.

Delivery Check Valve Replacement Kit

K092011

Desiccant Cartridge Replacement Kit (Standard)

5008414

Desiccant Cartridge Replacement Kit - Bendix

AD-9si

PuraGuard

®

air dryer (can be used to replace the standard

cartridge)

5008414PG

Governor Kit

K092010

Heater & Thermostat Replacement (12 volt)

109578

Heater & Thermostat Replacement (24 volt)

109579

Safety Valve Replacement

800155

Silencer Kit (not shown)

K021189

Wiring Harness & Splice Kit (not shown)

109871N

Extended Purge Kits (not shown)

93 in

3

Reservoir w/ 3/8"-16 U-bolts

5012561N

93 in

3

Reservoir w/ 1/2"-13 U-bolts

5005309N

288 in

3

Reservoir w/ 3/8"-16 U-bolts

5008972

Purge Valve Assembly

Type

Configuration

Service Kit

Pc. No.

Purge Valve Assembly for

climate conditions above

-40°C (-40°F)

Bendix

®

AD-9si

™

Air Dryer

K022105

AD-9si

™

Air Dryer

(Soft Seat Version)

K031560

AD-9si

™

Air Dryer

(Discharge Line Unloader)

K031562

Arctic Purge Valve Assembly

for climate conditions of

-40°C to -50°C

(-40°F to -58°F)

AD-9si Air Dryer

K031559

AD-9si Air Dryer

(Soft Seat Version)

K031561

AD-9si Air Dryer

(Discharge Line Unloader)

K031563

3. Apply and release the service brakes several times to

reduce system air pressure to governor cut-in. Note

that the system once again builds to full pressure and

is followed by a purge at the air dryer exhaust.

4. It is recommended that the total air system be tested

for leakage to ensure that the AD-9si air dryer will not

cycle excessively.

It is important to read and adhere to the following

instruction, to ensure the brake system operates safely

after bypassing the air dryer.

TEMPORARY AIR DRYER BYPASS

To temporarily bypass the air dryer, follow these procedures

and be sure to adhere to the General Safety Guidelines

outlined elsewhere in this document.

Make sure that all residual pressure has been released.

Slowly loosen the fitting that connects the air compressor

discharge line to the air dryer inlet port (IN 1) thereby

allowing any pressure trapped in the air dryer purge

reservoir to escape to the atmosphere. Once the pressure

has escaped and air flow has ceased, remove the fitting