Bendix Commercial Vehicle Systems AD-9si Oil Coalescing Air Dryer User Manual

Page 5

5

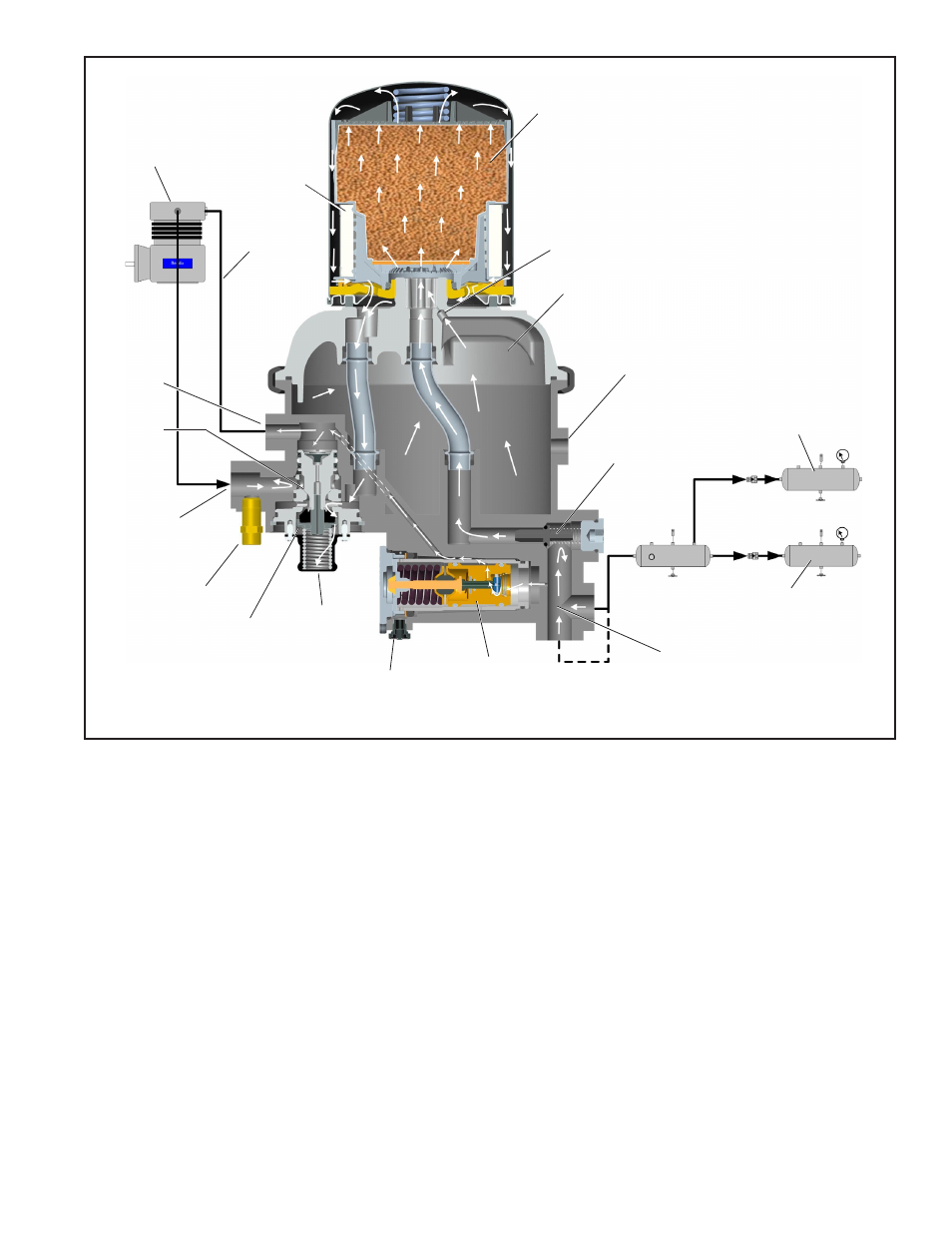

COMPRESSOR

GOVERNOR

DESICCANT

BED

DELIVERY

CHECK

VALVE

PURGE

VALVE

TURBO

CUT-OFF

VALVE

(CLOSED)

CONTROL

PORT

SUPPLY

PORT

FRONT

RESERVOIR

SAFETY

VALVE

REAR

RESERVOIR

PURGE

ORIFICE

OIL

COALESCING

FILTER

CONTROL

LINE

PURGE AIR

EXTENDED

PURGE

PORT

EXHAUST

EXHAUST

DELIVERY

PORT

FIGURE 3 -

BENDIX

®

AD-9si

™

AIR DRYER WITH GOVERNOR—PURGE CYCLE

valve (described in the "Turbo Cut-off Feature" section of

this document). Water and contaminants captured are

expelled immediately when the purge valve opens. In

addition, air — which was flowing through the desiccant

cartridge — changes direction and begins to flow from the

purge volume toward the open purge valve. Contaminants

collected by the air dryer filters and desiccant are removed

by air flowing from the purge volume through the desiccant

drying bed to the open purge valve.

The initial purge and desiccant cartridge decompression

lasts only a few seconds, evidenced by an audible burst

of air at the air dryer exhaust.

PURGE CYCLE

(Refer to Figures 3 and 5)

When air brake system pressure reaches the cut-out

setting of the governor, the integral governor unloads the

compressor by supplying a pressure signal through the

control port (CON 2-4). This signal activates the purge

cycle of the air dryer.

The governor unloads the compressor by allowing air

pressure to fill the line leading to the compressor unloader

mechanism. This suspends the delivery of compressed

air to the Bendix

®

AD-9si

™

air dryer.

Similarly, the governor also supplies this air pressure signal

to the purge valve. The pressure moves the air dryer purge

piston down, opening the purge valve to atmosphere and

closing off the compressor air supply to the turbo cut-off