Bendix Commercial Vehicle Systems AD-IS EVERFLOW User Manual

Page 5

5

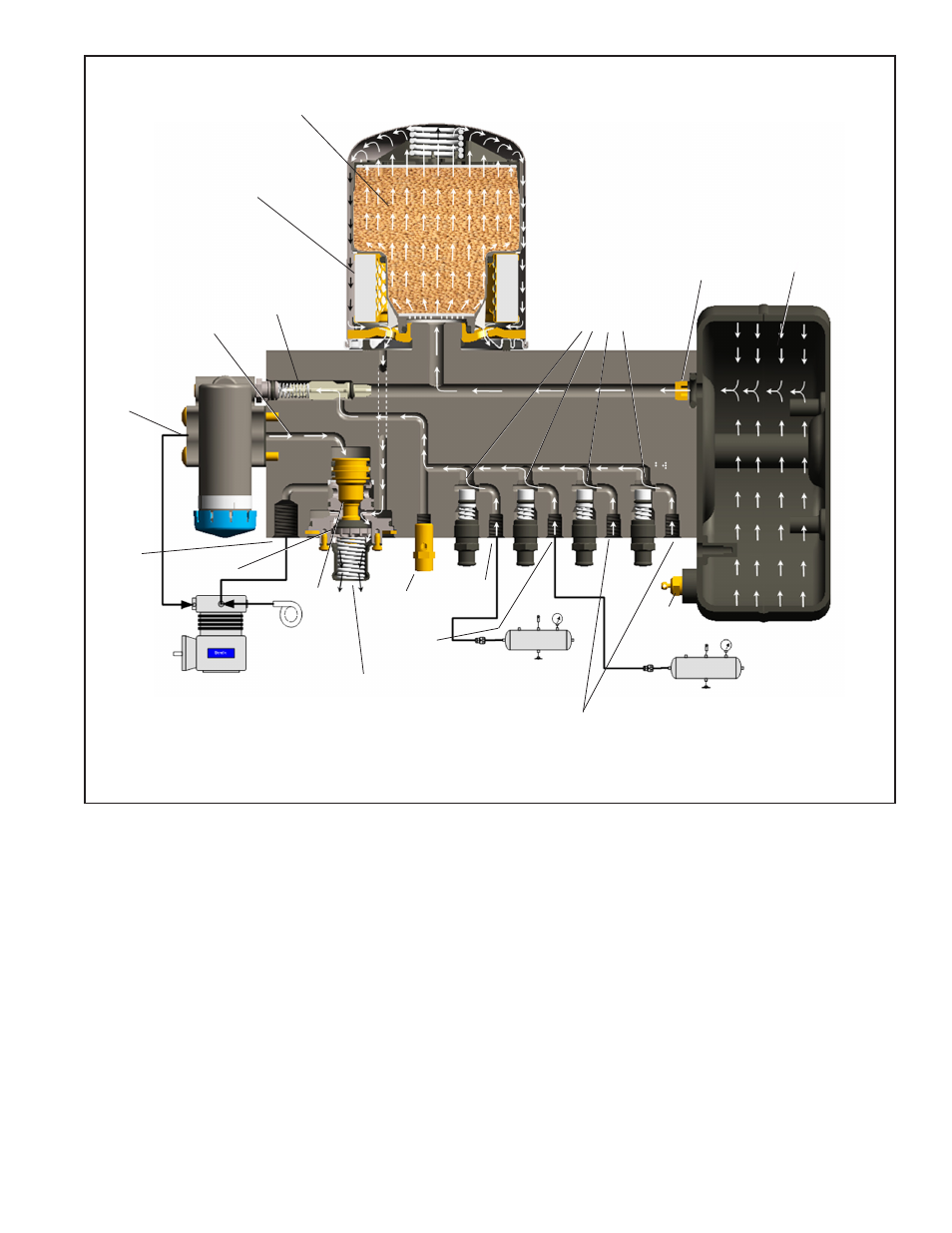

FIGURE 4 -

BENDIX

®

AD-IS

®

AIR DRYER AND RESERVOIR SYSTEM PURGE CYCLE

DIAGRAM SHOWS ALL PRESSURE

PROTECTION VALVES OPEN.

COMPRESSOR

GOVERNOR

DESICCANT

BED

DELIVERY

CHECK VALVE

(CLOSED)

PRIMARY

PORT (PRI)

PURGE VALVE

(OPEN)

TURBO

CUT-OFF

VALVE

(CLOSED)

ENGINE

TURBO

UNLOADER

PORT

SUPPLY

PORT

PRIMARY

RESERVOIR

PRESSURE

PROTECTION

VALVES

AUXILIARY PORTS

(TO ACCESSORIES)

EXHAUST

SAFETY

VALVE

PURGE

RESERVOIR

DRAIN VALVE

SECONDARY

RESERVOIR

SECONDARY

PORT (SEC)

PURGE

RESERVOIR

PURGE

ORIFICE

OIL COALESCING FILTER

(BENDIX

®

AD-IS

®

PURAGUARD

®

OIL COALESCING AIR DRYER)

A

D

C

B

PURGE

CONTROL

CHANNEL

Air then moves into the desiccant drying bed and becomes

progressively drier as water vapor adheres to the desiccant

material in a process known as “ADSORPTION.” Dry air

exits the desiccant cartridge through the delivery check

valve and also through an orifice into the purge reservoir.

The delivery check valve opens, supplying air to pressurize

the air brake system. The purge reservoir stores air that will

be used to reactivate the desiccant during the purge cycle.

From a flat system — approximately 80 psi — the Bendix

®

AD-IS

®

EverFlow

®

electronic module is actuated and

begins the purge cycle. When the air pressure reaches

the specified opening pressure — typically 106 psi — the

pressure protection valves will open and air will be supplied

to the primary reservoir, secondary reservoir or other

accessories. If the pressure protection valves are preset

to different values, the valves will open in order of lowest

setting to highest setting when charging a flat system.

The air dryer will remain in the charge cycle until the air

brake system pressure builds to the governor cut-out

setting of approximately 130 psi When air brake system

pressure reaches the cut-out setting of the governor,

the governor unloads the compressor and the electronic

module sends a signal to one of the air dryers to purge.

The governor unloads the compressor by allowing air

pressure to fill the line leading to the compressor unloader

mechanism — causing the delivery of compressed air to

the Bendix

®

AD-IS

®

EverFlow

®

assembly to be suspended.

Similarly, the governor also supplies air pressure to the

EverFlow

electronic module. The electronic module uses

this signal to determine the volume of air in the brake

system. If the volume is normal, the electronic module

sends a signal to the control port on the proper dryer. If the