Ad-is everflow, Air dryer operation, Normal brake cycle – Bendix Commercial Vehicle Systems AD-IS EVERFLOW User Manual

Page 4

4

AD-IS EVERFLOW

AIR DRYER OPERATION:

GENERAL

The Bendix

®

AD-IS

®

EverFlow

®

assembly alternates

between the dryers each time the brake system charges.

During high air demand, the dryers alternate every 30

seconds to allow drying of the added volume of air. A

pressure protection valve is needed after the dryers to

maintain at least 70 PSIG at the dryers during high air

demand. A Bendix

®

EverFlow

®

electronic module monitors

the air brake system and determines the amount of

demand. The AD-IS EverFlow assembly requires a

signal from the delivery port of the governor into the

GOV port of the EverFlow

electronic module. The AD-IS

EverFlow assembly also needs a supply air line from the

secondary tank to the electronic module RES port.

This

line must be 3/8 inch, or larger, tubing.

The AD-IS EverFlow assembly is primarily designed to dry

air on systems used for bulk unload and central tire inflation.

The system operates best when a pressure protection valve

is installed between the EverFlow assembly and the source

of the high volume air. Refer to the system schematics,

Figure 2. This pressure protection valve should have a

minimum pressure of 70 PSIG.

Delivery pressure in

excess of 175 PSIG can cause the purge valve to cycle

rapidly between load and purge mode.

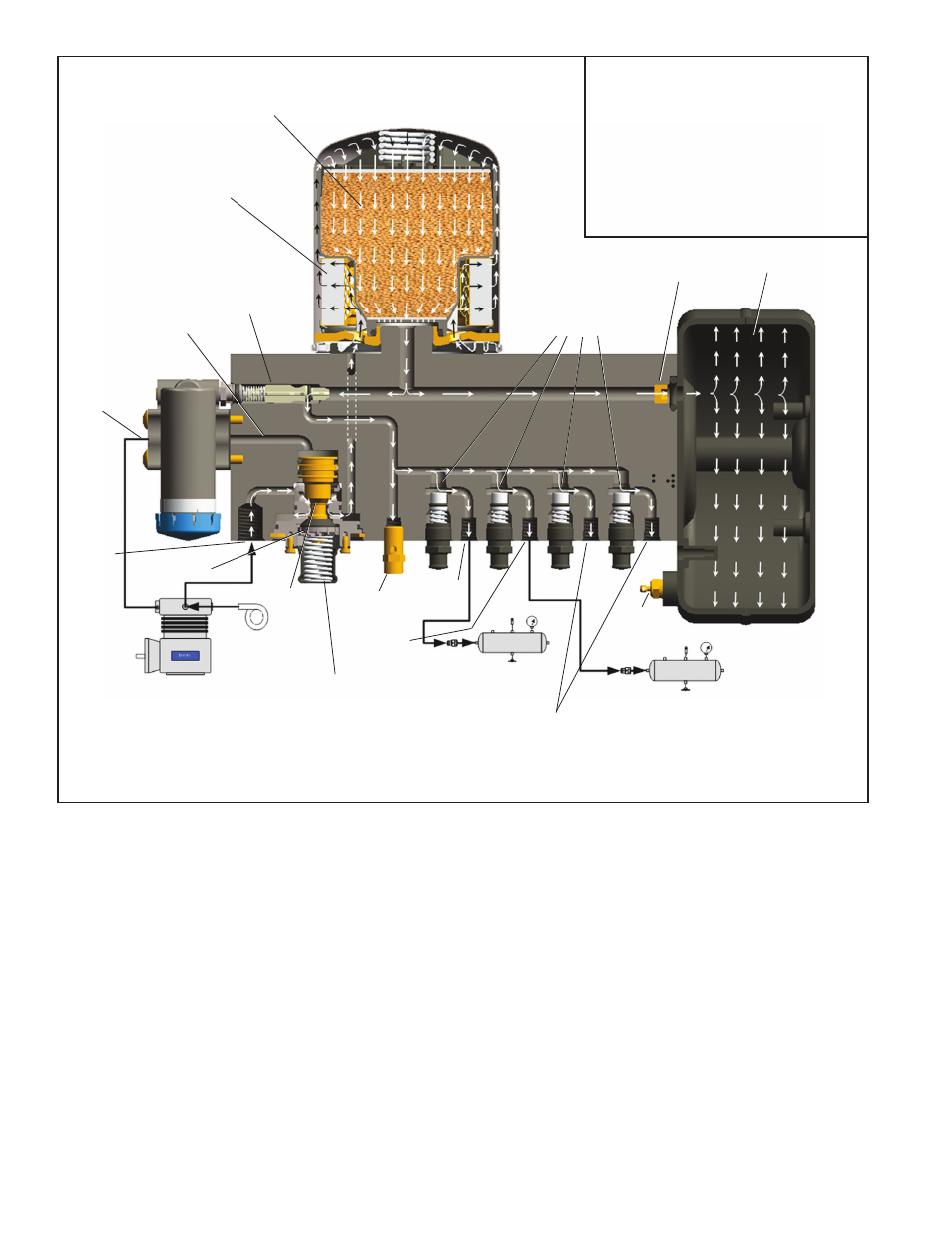

NORMAL BRAKE CYCLE

(Refer to Figures 3 & 4)

When the compressor is charging (compressing air) air

flows through the compressor discharge line to the inlet

(1 IN) port of one of the air dryers. The compressed air

includes contaminates such as oil, oil vapor, water and

water vapor. The air then flows into the desiccant cartridge,

where it flows through a liquid separator which collects

liquids and other contaminants.

COMPRESSOR

GOVERNOR

DESICCANT

BED

DELIVERY

CHECK VALVE

(OPEN)

PRIMARY

PORT (PRI)

PURGE VALVE

(CLOSED)

TURBO

CUT-OFF

VALVE

(OPEN)

ENGINE

TURBO

UNLOADER

PORT

SUPPLY

PORT

PRIMARY

RESERVOIR

PRESSURE

PROTECTION

VALVES

AUXILIARY PORTS

(TO ACCESSORIES)

SEE

NOTE 1

Note 1:

The Bendix

®

AD-IS

®

air dryer and reservoir

system purge piston has a purge control

channel drain. This allows any condensation

in this area to flow past a diaphragm in the

top of the purge piston and out through a

channel in the middle of the central bolt of

the purge assembly to be drained. During

the purge cycle this drain is closed.

SAFETY

VALVE

PURGE

RESERVOIR

DRAIN VALVE

SECONDARY

RESERVOIR

SECONDARY

PORT (SEC)

PURGE

RESERVOIR

PURGE

ORIFICE

OIL COALESCING FILTER

(BENDIX

®

AD-IS

®

PURAGUARD

®

OIL COALESCING AIR DRYER)

A

D

C

B

PURGE

CONTROL

CHANNEL

FIGURE 3 -

BENDIX

®

AD-IS

®

AIR DRYER AND RESERVOIR SYSTEM CHARGE CYCLE