Bendix Commercial Vehicle Systems AD-IS EVERFLOW User Manual

Page 11

11

ASSEMBLY

1. Lubricate the smaller o-ring and check valve body with

a heavy-duty lithium grease.

2. Install this o-ring on the check valve body by sliding the

o-ring over the set of four tapered guide lands. The

o-ring groove holds the o-ring in its correct location.

3. At the other end of the check valve body, the spring is

installed over the set of four straight guide lands. When

the spring has been pushed to the correct location, the

check valve body is designed to hold the end of the

spring in position: be sure that the spring is not loose

before continuing with this installation.

4. Install the assembled check valve body/o-ring/spring

in the delivery port so that the o-ring rests on its seat

and the free end of the spring is visible.

5. Grease the adapter and the remaining larger o-ring and

install it onto the fitting.

6. Position the governor gasket, then insert the governor

mounting bolts through the governor and tighten (to

125 in-lbs). Note: Do not replace with a standard

compressor/governor gasket.

7. Re-attach the air line to the governor.

8. Before placing the vehicle back into service, check

to see that the system pressure now builds to full

operational pressure.

TESTING THE EVERFLOW

®

ASSEMBLY AIR DRYERS

Before placing the vehicle in service, perform the following

tests:

1. Close all reservoir drain valves.

2. Build up system pressure to governor cut-out and note

that one of the AD-IS

®

EverFlow

®

Assembly air dryers

purges with an audible burst of air, followed immediately

by approximately 30 seconds of air flowing out of the

purge valve.

3. Apply and release the service brakes several times to

reduce system air pressure to governor cut-in. Note

that the system once again builds to full pressure and

is followed by a purge at the other AD-IS EverFlow

assembly air dryer exhaust.

4. It is recommended that the total air system be tested for

leakage to ensure that the AD-IS EverFlow assembly

air dryers will not cycle excessively.

See Bendix publication BW5057 “Air Brake Handbook.”

TROUBLESHOOTING THE AD-IS

®

EVERFLOW

®

ASSEMBLY

Consult the Bendix

®

AD-IS

®

air dryer service data sheet,

SD-08-2418, for air dryer maintenance and service

information.

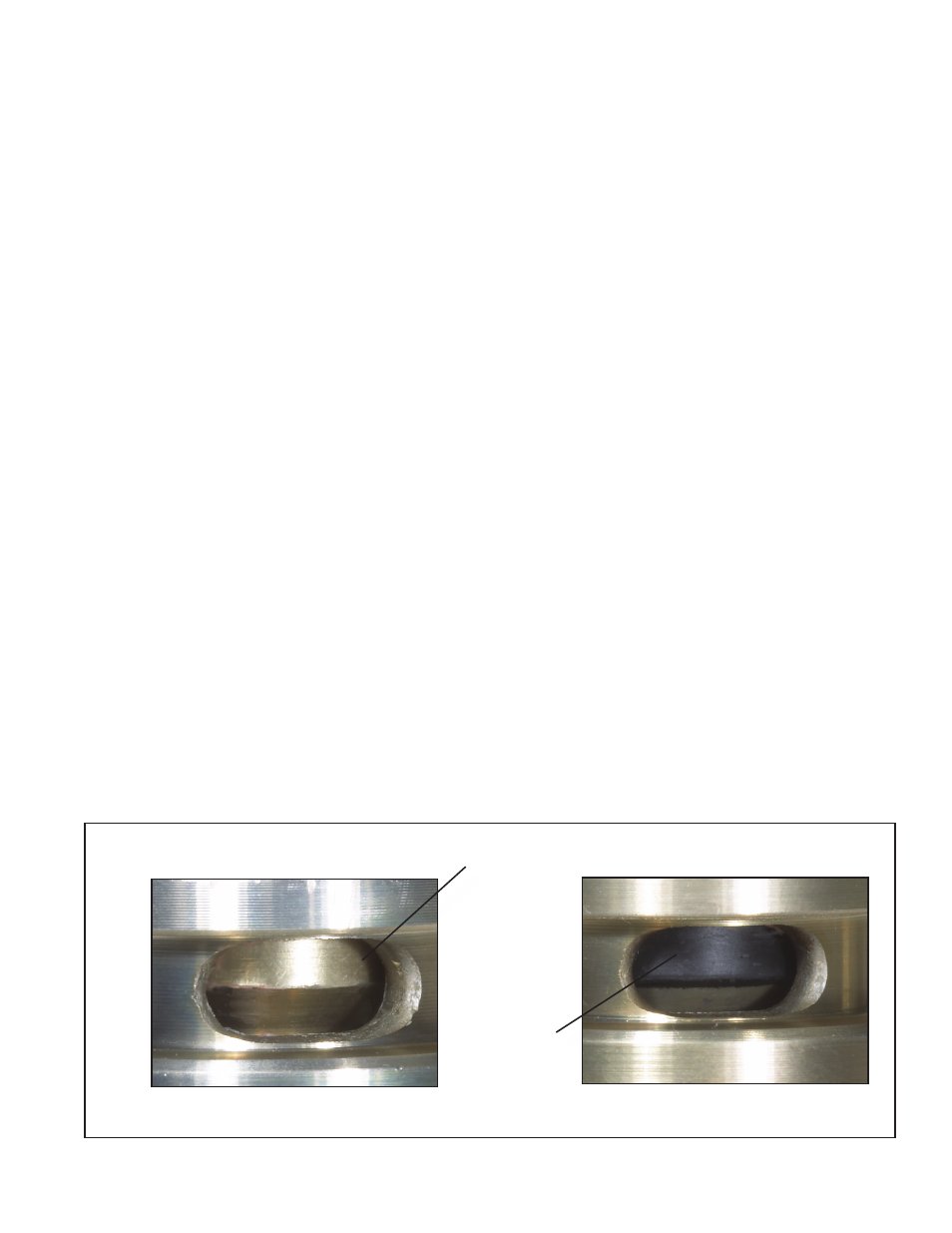

1. Excessive dryer purging in the loaded cycle.

• The purge valves in both dryers must have soft-seat

turbo cut-off valves. See Figure 7. Remove the purge

valve an examine the upper window, replace with soft

seat purge valve.

METAL

BLACK

RUBBER

FIGURE 7-

IDENTIFICATION OF HARD AND SOFT SEAT PURGE VALVES

HARD SEAT

SOFT SEAT