The bendix, Versajust, Slack adjuster troubleshooting chart – Bendix Commercial Vehicle Systems VERSAJUST AUTOMATIC SLACK ADJUSTER User Manual

Page 8

8

The Bendix

®

Versajust

™

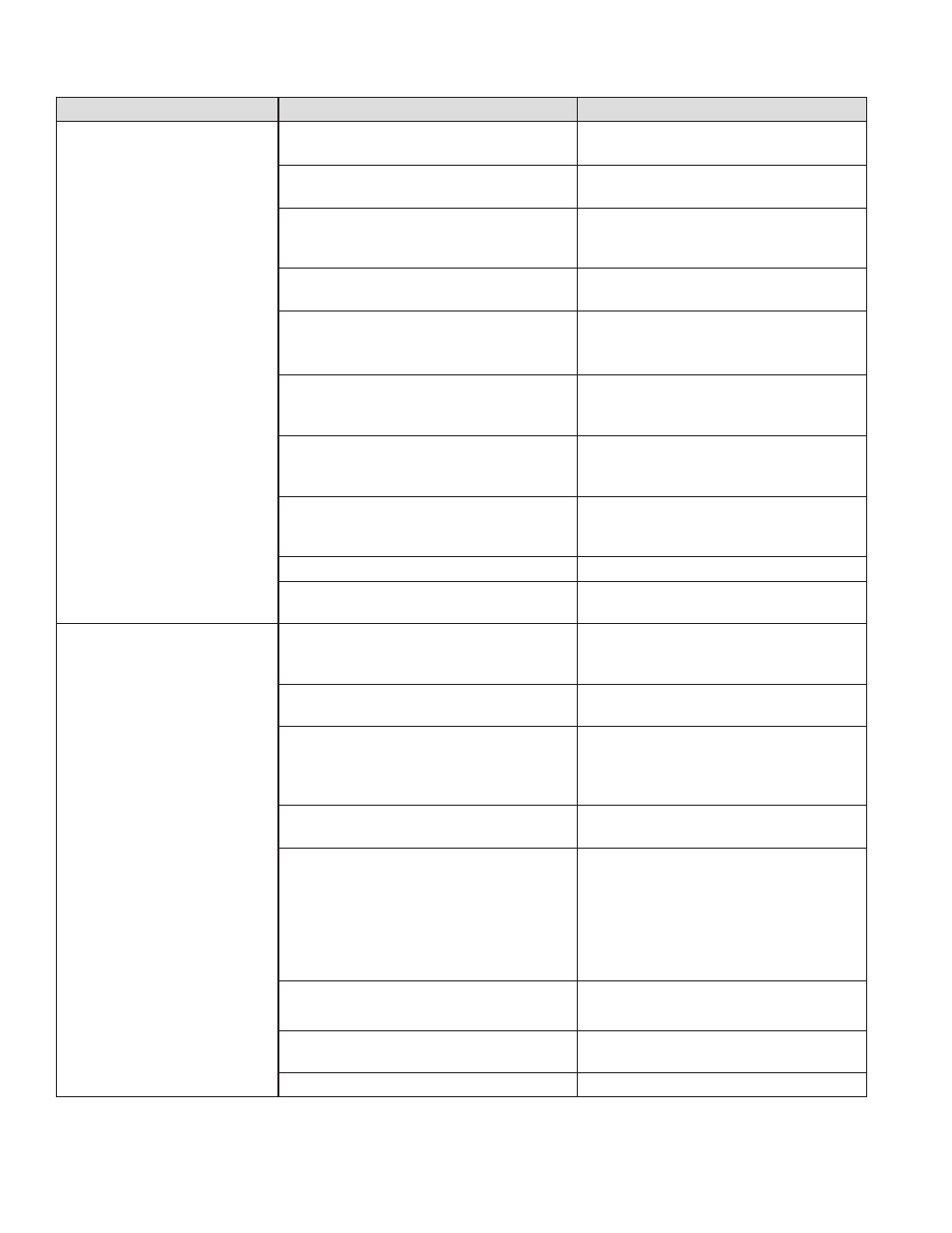

Slack Adjuster Troubleshooting Chart

Symptom

Cause

Remedy

1. Brake Actuator stroke is

too long.

WARNING: Automatic

slack adjusters should

not be manually

adjusted in an effort to

correct excessive push

rod stroke, because this

condition indicates that

a problem exists with

the automatic adjuster,

with the installation of

the adjuster, or with

related foundation

brake components,

which manual

adjustment will not fix.

A. Loose actuator push rod jam nut.

A. Reposition components and torque to

specification.

B. Excessive clearance between adapter/

adapter bushing and yoke due to wear.

B. Replace damaged or worn parts.

C. Excessive clearance between

components: yoke pin — yoke link pin —

link yoke pin — body.

C. Replace worn parts.

D. Damaged (worn)

splines on slack or camshaft.

D. Replace damaged parts.

E. Weak or broken brake actuator return

springs. Weak or broken brake shoe

return spring.

E. Replace weak or broken springs.

F. Worn or broken foundation brake

components, including camshaft

bushings, brake chamber bracket, etc.

F. Repair or replace as required per In

Service Inspection.

G. Versajust adjuster mechanism not

functioning.

G. Lubricate, test adjuster mechanism,

conduct in service inspection, repair

components as necessary, replace.

H. Brake drum—worn, excessively

machined, bell-mouthed,

excessive thermal expansion.

H. Replace or repair as required.

I. Damaged Versajust slack adjuster.

I. Replace component(s) or slack adjuster.

J. Versajust slack adjuster improperly

installed.

J. Correct installation position.

2. Brakes dragging —

apparent over-adjustment

of brakes.

A. Versajust slack adjuster improperly

installed. Too close to actuator: brakes

can’t fully release.

A. Correct the Versajust slack adjuster

installation.

B. Loose actuator push rod jam nut.

B. Reposition components and torque to

specification.

C. Spring brakes not fully retracting.

C. Check spring brake release air pressure

and repair or replace air valving as

necessary. Repair or replace spring

brake.

D. Broken foundation brake components,

including camshaft bushings.

D. Repair or replace as required per In

Service Inspection.

E. Vehicle brake torque imbalance. (More

work done by some brakes than others,

thermal expansion of drums).

E. Check other brakes to ensure they are

working. Check air pressure balance

and threshold pressure (refer to Bendix

publication BW1555). Check driver

braking habits, e.g. use of trailer control

valve. Use same friction material on all

axles.

F. Brake drum out-of-round, excessive

thermal expansion.

F. Replace or repair as required.

G. Air system malfunction, not exhausting

completely.

G. Inspect and correct.

H. New lining swells during break-in.

H. Back-off adjustment until brakes are free.

CHART 4 - TROUBLESHOOTING SYMPTOM/CAUSE/REMEDY

BW7499 © 2011 Bendix Commercial Vehicle Systems LLC. All Rights Reserved. 03/11 Printed in U.S.A.