Brake maintenance inspection, Bendix, Versajust – Bendix Commercial Vehicle Systems VERSAJUST AUTOMATIC SLACK ADJUSTER User Manual

Page 6: Slack adjuster removal, Testing the bendix, Adjuster mechanism

6

BRAKE MAINTENANCE INSPECTION

Note: Make certain the vehicle has been prepared

according to the instructions under the heading GENERAL

SAFETY GUIDELINES in this manual.

The following test can be used to inspect the maintenance

condition of the foundation brake and to determine how

much of the chamber stroke is caused by the condition of

the foundation brake.

1. Always chock the wheels to keep the vehicle from

moving.

2. Raise the axle so the wheel can be rotated.

3. Adjust the slack adjuster to produce light brake drag

with wheel rotation.

4. Apply the brake to 80-90 psi and measure the stroke

(See Item 3 of In Service Inspection for pressure tips).

5. If the stroke significantly exceeds the values shown in

Chart 3 below, the brake may be out of the norm, and

brake maintenance may be required.

AL

Factor

15"x4"

Front

Brake

16.5"x7"

Tractor, Truck

or Bus Brake

16.5"x7"

Trailer

Brake

12 X 5.0"

1

/

2

"

N/A

N/A

12 X 5.5"

1

/

2

"

N/A

N/A

16 X 5.0"

5

/

8

"

1

/

2

"

N/A

16 X 5.5"

3

/

4

"

1

/

2

"

N/A

16 X 6.0"

7

/

8

"

5

/

8

"

N/A

20 X 5.0"

5

/

8

"

1

/

2

"

3

/

8

"

20 X 5.5"

3

/

4

"

5

/

8

"

1

/

2

"

20 X 6.0"

7

/

8

"

3

/

4

"

5

/

8

"

24 X 5.0"

N/A

5

/

8

"

1

/

2

"

24 X 5.5"

N/A

5

/

8

"

5

/

8

"

24 X 6.0"

N/A

3

/

4

"

5

/

8

"

30 X 5.0"

N/A

3

/

4

"

5

/

8

"

30 X 5.5"

N/A

7

/

8

"

3

/

4

"

30 X 6.0"

N/A

1"

7

/

8

"

CHART 3 - AL FACTOR

BENDIX

®

VERSAJUST

™

SLACK

ADJUSTER REMOVAL

Note: Make certain the vehicle has been prepared

according to the instructions under the heading GENERAL

SAFETY GUIDELINES in this manual.

1. If the Versajust slack adjuster is equipped with the

easy-on yoke assembly illustrated in Figure 2:

A. Loosen the brake actuator push rod jam nut

and run it back on the brake actuator push rod

approximately

5

/

8

inch.

B. Loosen the easy-on yoke adapter and run it back

on the brake actuator push rod until it is free of the

yoke.

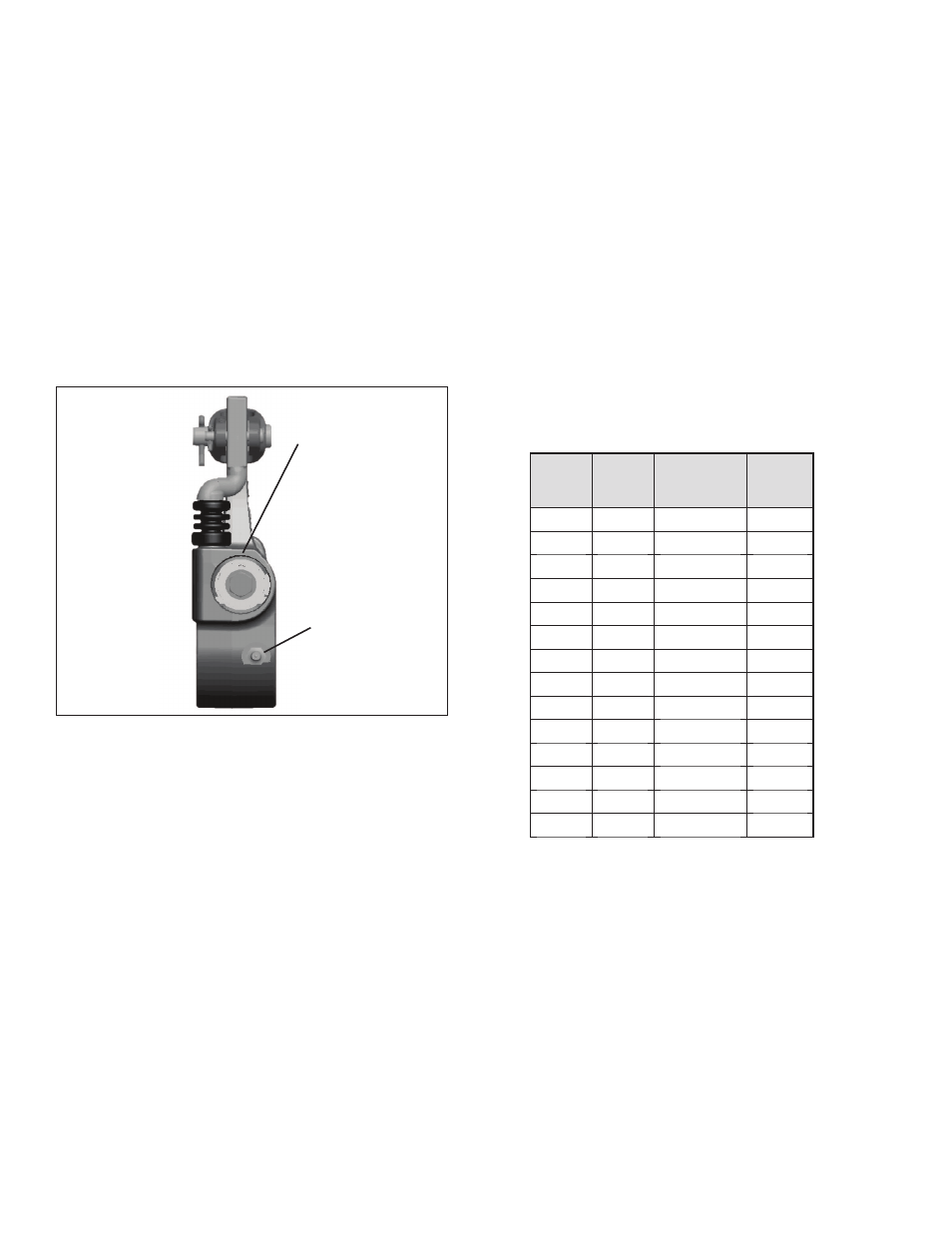

TESTING THE BENDIX

®

VERSAJUST

™

ADJUSTER MECHANISM

The following test can be made to determine if the Bendix

®

Versajust

™

adjuster mechanism is functioning properly.

1. With the brakes released and the vehicle wheels

blocked, de-adjust the brakes by rotating the manual

adjustment hex counterclockwise approximately

1

/

2

to

1 revolution.

Note: Considerable torque is required to rotate the

manual adjustment hex counterclockwise and should

be considered normal. The required torque may be as

high as 70 foot pounds.

2. Using a straight edge, scribe a line across the manual

adjustment hex head and slack adjuster body. (Refer

to Figure 6).

ADJUSTER HEX

ROTATES

CLOCKWISE

DURING

ADJUSTMENT

GREASE

FITTING

FIGURE 6 - TESTING ADJUSTER MECHANISM

3. Apply, and COMPLETELY RELEASE, the service

brakes several times while observing the manual

adjustment hex and the scribed line. The Bendix

Versajust slack adjuster manual adjustment hex

should rotate clockwise during the application and

remain stationary during release. No counterclockwise

rotation of the hex should be observed. The

amount of clockwise rotation (adjustment) will

decrease progressively as the brake nears proper

adjustment. If the Versajust slack adjuster fails to

perform as described, it will be necessary to repair or

replace it.

4. Manually re-adjust the Versajust slack adjuster being

tested before returning the vehicle to service. (See

section Installation, Step 6)

Note: While it is possible to use the automatic adjustment

feature of the Versajust slack adjuster to bring the brake back

into adjustment, this process will require numerous applications

and COMPLETE RELEASES (the number of applications

depends on how much the slack was de-adjusted).