Bendix Commercial Vehicle Systems VERSAJUST AUTOMATIC SLACK ADJUSTER User Manual

Page 5

5

3. Measure the brake actuator push rod stroke while

making an 80-90 psi service brake application. Actuator

push rod strokes should not exceed the values shown in

Chart 2, on this page. The correct pressure for this test

can be achieved as follows: Build the system pressure

up to a 100 psi reading on the vehicle gauge. Shut the

engine off. Fan the brakes to attain a 90-95 psi reading.

Make and hold a full brake application while the strokes

are checked.

IF THE SLACK ADJUSTER DOES NOT

AUTOMATICALLY ADJUST THE BRAKES

If the actuator stroke exceeds those shown in the

stroke table, inspection of the foundation brake and/or

the automatic slack is necessary. Maintenance of the

foundation brake may be a factor in the excessive stroke

conditions. Inspecting the foundation brake – per the

Brake Maintenance Inspection presented in this manual –

should determine how much of the long stroke condition

is caused by the condition of the foundation brake. The

Bendix Versajust slack adjuster can be tested using the

instructions presented in this manual under "Testing

the Bendix

®

Versajust

™

Adjuster Mechanism." The

automatic slack adjuster is not designed to function as a

manual adjuster once it is unable to maintain adjustment

automatically. Manual adjustment should be done only as

a temporary measure to correct brake adjustment in an

emergency situation. The routine manual adjustment of

an automatic slack adjuster that is still within adjustment

limits may shorten its service life. Automatic slack adjusters

should not be manually adjusted in an effort to correct

excessive push rod stroke. This condition indicates that

a problem exists with the automatic adjuster; with the

installation of the adjuster; or with related foundation

brake components, which manual adjustment will not

fix. Replacement of the automatic slack adjuster or other

foundation brake components may be necessary. Consult

with the manufacturer's troubleshooting guidelines to find

and fix the problem.

WARNING:

Manual adjustment of automatic slack

adjusters is a dangerous practice that could have

serious consequences. This is because it can give

the operator a false sense of security about the

effectiveness of the brakes, which are likely to go

out of adjustment again soon. Do not make manual

adjustments of an automatic slack adjuster once it

can no longer automatically adjust the brakes. Manual

adjustment DOES NOT fix the underlying wheel end

adjustment problem. As soon as possible, have the

vehicle inspected by a qualified technician or consult

the manufacturer's troubleshooting guidelines to find

and fix the problem.

2. Lubricate the automatic slack adjuster through the lube

fitting with a quality multipurpose chassis lubricant

(N.L.G.I. Grade 2).

Lubricate the slack adjuster until clean lubricant flows

from the grease relief opening in the boot.

3. Perform the In Service Inspection described in this

manual.

IN SERVICE INSPECTION

1. Apply and release the vehicle brakes several times

while observing the Bendix

®

Versajust

™

slack adjuster.

The Versajust slack adjuster and brake actuator should

move freely, without binding or interference, and

should return to the full released position. Observe

the looseness that exists between the yoke and

adapter bushing and the yoke and link pins and their

mating parts (yoke, body, link). Replace these parts if

looseness appears excessive. Make certain the brake

actuator push rod jam nut is tight against the yoke

adapter.

2. Inspect the Versajust slack adjuster for physical

damage, paying particular attention to the link, boot,

and yoke. Inspect for bent, broken, loose, or misaligned

brake actuator push rods and cracked or damaged

brake actuator brackets. Repair or replace any

components found to be damaged.

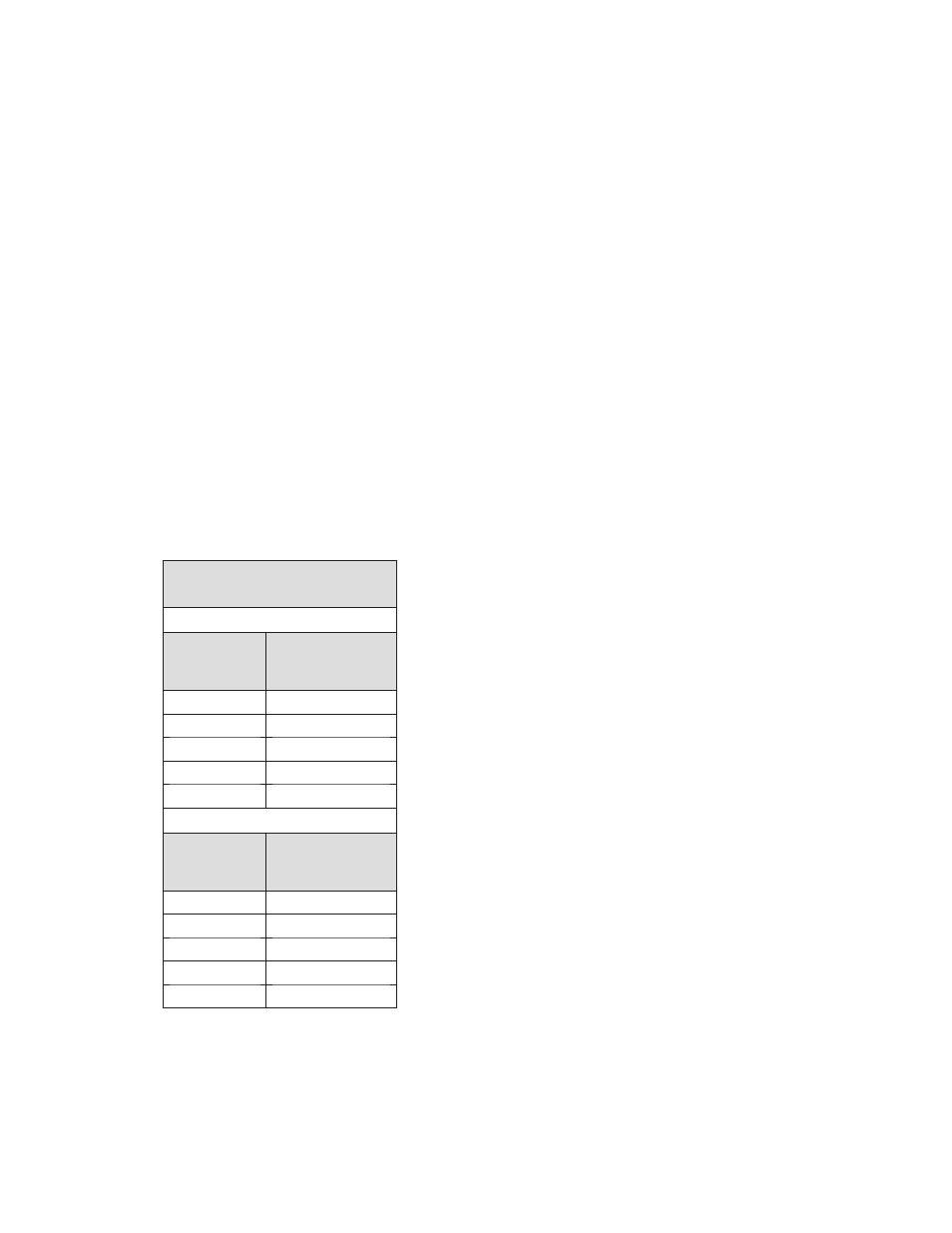

ACTUATOR

STROKE TABLE

STANDARD STROKE

Brake Actuator

Size

Recommended

Maximum

Operating Stroke

30

2"

24

1

3

/

4

"

20

1

3

/

4

"

16

1

3

/

4

"

12

1

3

/

8

"

LONG STROKE

Brake Actuator

Size

Recommended

Maximum

Operating Stroke

30LS

2

1

/

2

"

24L

2"

24LS

2

1

/

2

"

20L

2"

16L

2"

CHART 2 - ACTUATOR STROKE TABLE