Bendix Commercial Vehicle Systems AD-9 IPC AIR DRYERS 4/11 User Manual

Page 4

4

AD-9 CHARGE MODE

BW

The initial purge and desiccant cartridge decompression

lasts only a few seconds and is evidenced by an audible

burst of air at the Bendix

®

AD-9

®

or AD-9

®

IPC air dryer

exhaust.

The actual reactivation of the desiccant drying bed begins

as dry air fl ows from the purge volume through the desiccant

cartridge purge orifi ce and into the desiccant drying bed.

Pressurized air from the purge volume expands after

passing through the purge orifi ce; its pressure is lowered

and its volume increased. The fl ow of dry air through the

drying bed reactivates the desiccant material by removing

the water vapor adhering to it. Generally 15–30 seconds are

required for the entire purge volume of a standard Bendix

AD-9

or AD-9 IPC air dryer to fl ow through the desiccant

drying bed.

The end cover single check valve assembly prevents air

pressure in the brake system from returning to the air dryer

during the purge cycle. After the 30 second purge cycle is

complete, the air dryer is ready for the next charge cycle

to begin.

The purge valve will remain open after the purge cycle is

complete, and will not close until air brake system pressure

is reduced and the governor signals the compressor to

charge.

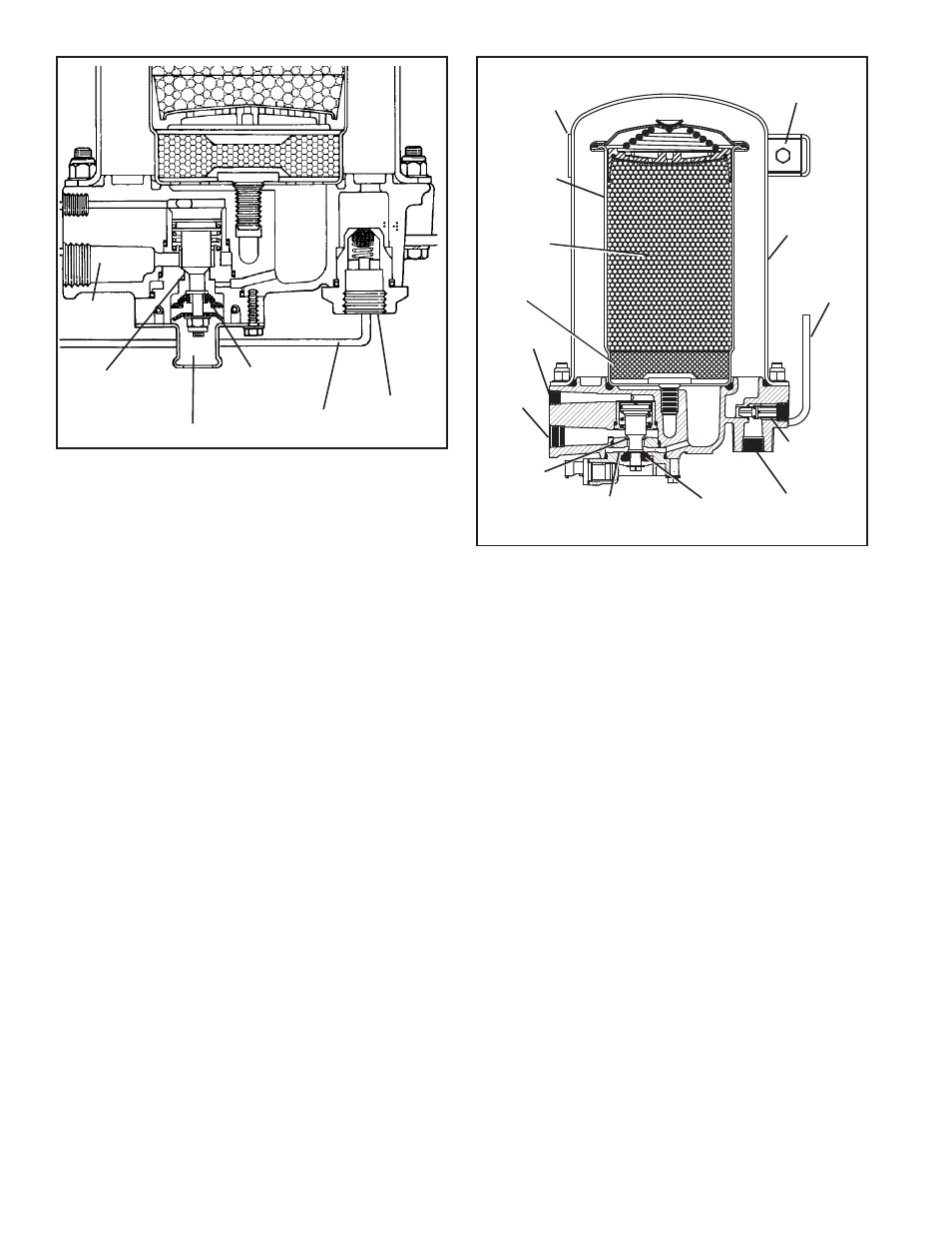

TURBO CUT-OFF FEATURE (Refer to Figure 4)

The primary function of the turbo cut-off valve is to prevent

loss of engine turbocharger air pressure through the

Bendix AD-9 and AD-9 IPC air dryers in systems where the

compressor intake is connected to the engine turbocharger.

The turbo cut-off valve also reduces the “puffi ng” of air out

the open exhaust when a naturally aspirated, single cylinder

compressor equipped with an inlet check valve is in use.

At the onset of the purge cycle, the downward travel of

the purge piston is stopped when the turbo cut-off valve

(tapered portion of purge piston) contacts its mating metal

seat in the purge valve housing. With the turbo cut-off valve

seated (closed position), air in the discharge line and air

dryer inlet port is restricted from entering the air dryer. While

the turbo cut-off effectively prevents loss of turbocharger

boost pressure to the engine, some “seepage” of air may

be detected under certain conditions of compressor engine

and turbocharger operation. Even so, there will always be

low pressure trapped in the discharge line.

PREVENTIVE MAINTENANCE

Important: Review the warranty policy before performing

any intrusive maintenance procedures. An extended

warranty may be voided if intrusive maintenance is

performed during this period. Note: It is acceptable for

the purge valve to be maintained as necessary, (i.e., the

installation of a purge valve maintenance kit), without

voiding the warranty.

Because no two vehicles operate under identical

conditions, maintenance and maintenance intervals will

vary. Experience is a valuable guide in determining the

best maintenance interval for any one particular operation.

FIGURE 4 -

BENDIX

®

AD-9

®

AND AD-9

®

IPC AIR DRYER

TURBO CUT-OFF

UPPER

BRACKET

CHECK

VALVE

ASSEMBLY

SUPPLY

PORT

UPPER

BRACKET

STRAP

DESICCANT

CARTRIDGE

LOWER

BRACKET

HOUSING

CHECK

VALVE

ASSEMBLY

DISCHARGE

LINE

TURBO

CUT-OFF

PISTON

EXHAUST

PURGE

VALVE

TURBO

CUT-OFF

PISTON

PURGE VALVE

HOUSING

ASSEMBLY

PURGE

VALVE

DISCHARGE

PORT

FIGURE 5 - BENDIX

®

AD-9

®

AND AD-9

®

IPC AIR DRYER

CROSS SECTION

DESICCANT

BED

OIL

SEPARATOR

CONTROL

PORT

SUPPLY

PORT