Bendix Commercial Vehicle Systems AD-9 IPC AIR DRYERS 4/11 User Manual

Page 3

3

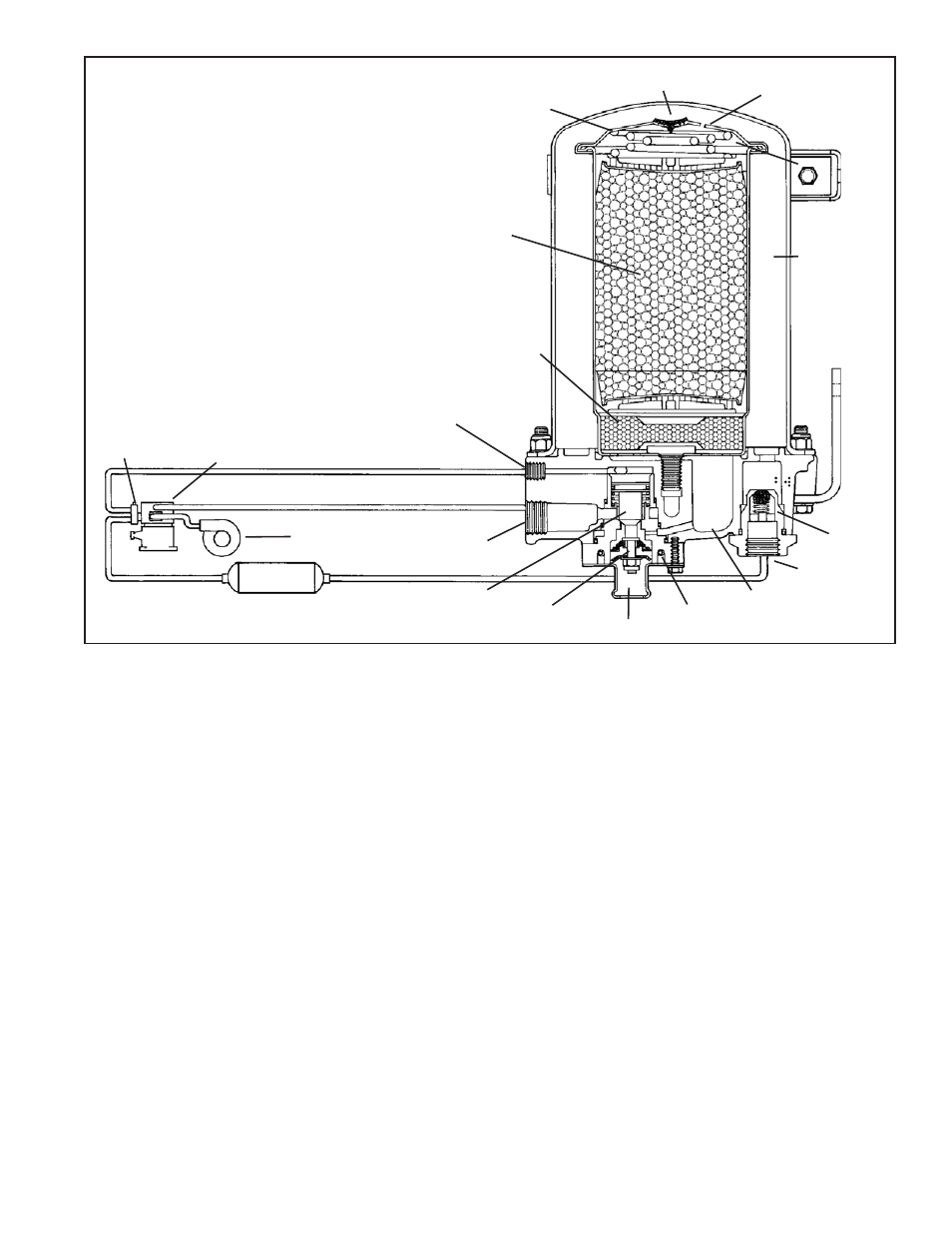

CHECK

VALVE

ORIFICE

PURGE

VOLUME

DELIVERY

PORT

HEATER

ELEMENT

SUMP

EXHAUST

PURGE

VALVE

RESERVOIR

SUPPLY

PORT

COMPRESSOR

GOVERNOR

ENGINE

TURBO

CONTROL

PORT

OIL

SEPARATOR

DESICCANT

BED

DESICCANT

CARTRIDGE

TURBO

CUT-OFF

PISTON

CHECK

VALVE

ASSEMBLY

FIGURE 3 - BENDIX

®

AD-9

®

AND AD-9

®

IPC AIR DRYER PURGE CYCLE

changes several times, reducing the temperature, causing

contaminants to condense and drop to the bottom, or sump,

of the air dryer end cover.

After exiting the end cover, the air fl ows into the desiccant

cartridge. Once in the desiccant cartridge, air fi rst fl ows

through an oil separator which removes water in liquid form

as well as oil and solid contaminants.

Air exits the oil separator and enters the desiccant drying

bed. Air fl owing through the column of desiccant becomes

progressively drier as water vapor adheres to the desiccant

material in a process known as “adsorption”. The desiccant

cartridge using the adsorption process typically removes

95% of the water vapor from the pressurized air.

The majority of dry air exits the desiccant cartridge through

its integral single check valve to fi ll the purge volume

between the desiccant cartridge and outer shell. Some

air will also exit the desiccant cartridge through the purge

orifi ce adjacent to the check valve.

Dry air fl ows out of the purge volume through the single

check valve assembly and out the delivery port to the fi rst

(supply) reservoir of the air system.

The air dryer will remain in the charge cycle until air brake

system pressure builds to the governor cut-out setting.

PURGE CYCLE (Refer to Figure 3)

When air brake system pressure reaches the cut-out setting

of the governor, the compressor unloads (air compression

stopped), and the purge cycle of the air dryer begins. When

the governor unloads the compressor, it pressurizes the

compressor unloader mechanism and line connecting the

governor unloader port to the air dryer end cover control

port. The purge piston moves in response to air pressure,

causing the purge valve to open to atmosphere and

(partially) closing off the supply of air from the compressor.

(This will be further discussed in the section covering

the turbo cut-off feature.) Contaminants in the end cover

sump are expelled immediately when the purge valve

opens. Also, air – which was fl owing through the desiccant

cartridge – changes direction and begins to fl ow toward

the open purge valve. Oil and solid contaminants collected

by the oil separator are removed by air fl owing from the

desiccant drying bed to the open purge valve.