Cleaning & inspection – Bendix Commercial Vehicle Systems AD-9 IPC AIR DRYERS 4/11 User Manual

Page 13

13

Heater and Thermostat Assembly Removal

1. Remove the two screws that secure the heater and

thermostat assembly to the purge valve assembly. See

Figure 9, illustration L for kit contents.

CAUTION

DO NOT PULL THE HEATER & THERMOSTAT

ASSEMBLY STRAIGHT OUT OF THE PURGE VALVE

BODY! READ STEP 2 COMPLETELY BEFORE

ATTEMPTING REMOVAL.

2. Study Figure 10 closely and note the "Y" shape of the

Heater & Thermostat assembly in its installed position

in the purge valve housing. As illustrated, remove the

heater & thermostat assembly by gently "rotating" the

connector to the left (Step A) until the thermostat clears

the purge valve housing, then slide the heater element

out, to the right and up (Step B).

End Cover Removal

1. Remove the remaining six 3/8" cap screws, locknuts

and twelve special washers that secure the end cover to

the housing air dryer housing. Separate the end cover

and desiccant cartridge from the housing. See Figure

9, illustration K.

2. Remove the end cover to outer housing o-ring.

3. Do not remove the safety valve from the end cover

unless it has been proven defective. If replacement

is required, apply thread sealant or Teflon

®

tape on

the threads of the replacement valve and torque

to 120–400 in. lbs. See Figure 1 for safety valve

location.

4. Place a strap or chain wrench around the desiccant

cartridge so that it is approximately 2–3 inches

away from the end cover. Rotate the cartridge

counterclockwise until it completely separates from the

end cover.

Note: A substantial torque (up to 50 lb. ft.) may be

required to perform this disassembly.

5. Remove the desiccant cartridge o-ring from the end

cover.

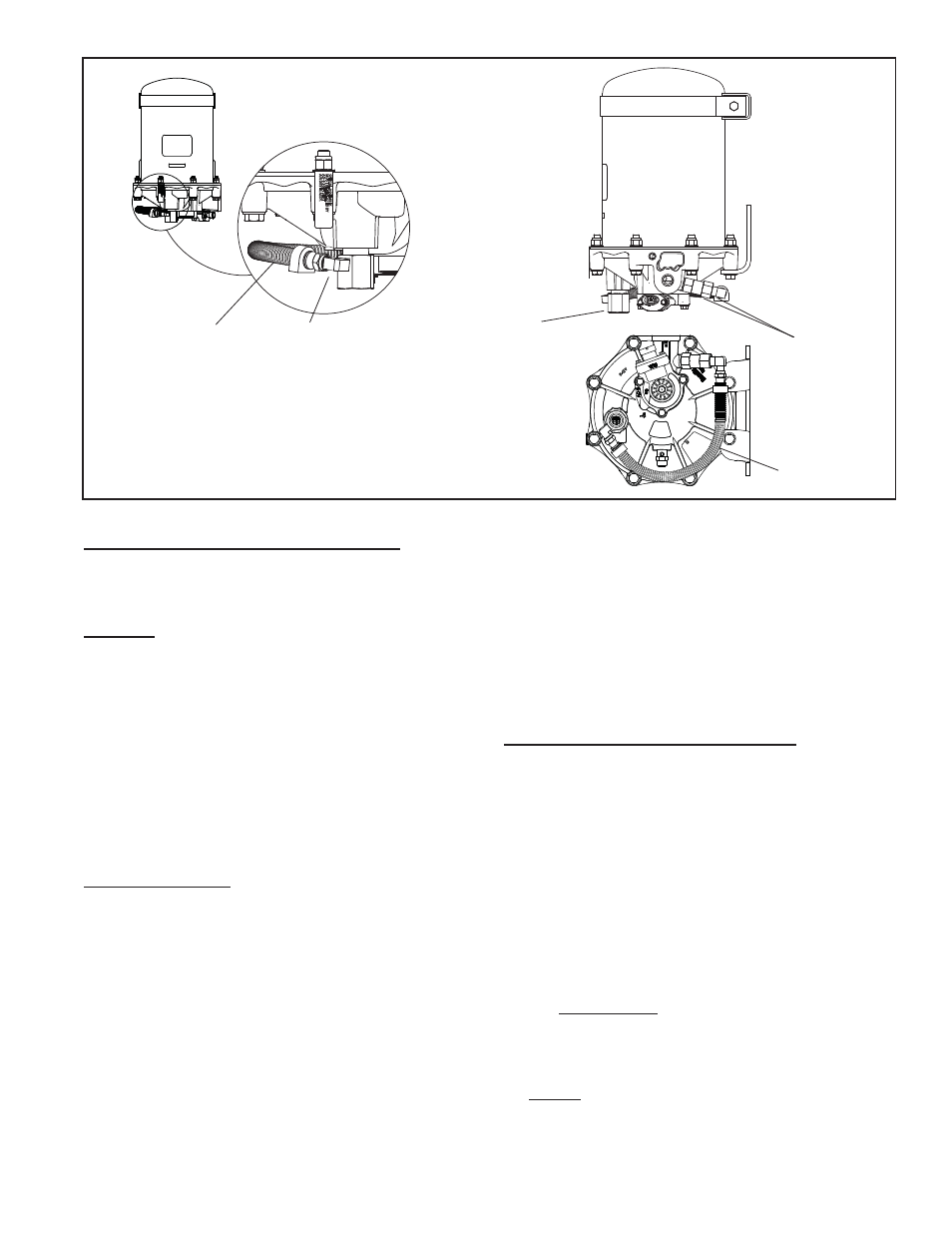

Drop In Air Dryer Makeup Line Removal

1. Before beginning, note the approximate angle of

the fittings, check valve and the general routing of

the makeup line on the air dryer. It is important that

the same approximate routing be duplicated during

re-installation. See Figure 11.

2. Disconnect the makeup line from the 90 degree fi tting

on the check valve.

3. Disconnect the makeup line from the 90 degree fi tting

on the port adapter itself or the check valve. Remove

the adapter along with the attached 90 degree fi tting.

CLEANING & INSPECTION

1. Using mineral spirits or an equivalent solvent, clean

and thoroughly dry all metal parts.

2. Inspect the interior and exterior of all metal parts

that will be reused for severe corrosion, pitting and

cracks. Superficial corrosion and/or pitting on the

exterior portion of the upper and lower body halves is

acceptable.

3. Inspect the bores of both the end cover and the purge

valve housing for deep scuffi ng or gouges.

DELIVERY PORT

ADAPTER

(WITH 90° FITTING)

DELIVERY PORT

ADAPTER

(WITH 90° FITTING)

MAKEUP AIR LINE

CHECK VALVE

(WITH 90° FITTING)

SPECIAL ASSEMBL

Y,

MUST BE REPLA

CED B

Y

AD

-9 SOFT SEA

T

AIR DR

YER ASSY

.

SPECIAL ASSEMBL

Y,

MUST BE REPLA

CED B

Y

AD

-9 SOFT SEA

T

AIR DR

YER ASSY

.

FIGURE 11 - BENDIX

®

AD-9

®

DROP IN AIR DRYER

MAKEUP AIR LINE