Bendix, Ad-9, And ad-9 – Bendix Commercial Vehicle Systems AD-9 IPC AIR DRYERS 4/11 User Manual

Page 21: Ipc air dryer troubleshooting chart

21

Bendix

®

AD-9

®

AND AD-9

®

IPC AIR DRYER TROUBLESHOOTING CHART

SYMPTOMS

CAUSE

REMEDY

1. Dryer is constantly “cycling”

or purging. Dryer purges

frequently (every 4 minutes

or less while vehicle is idling)

(continued).

A. Excessive system leakage.

IMPORTANT: Note whether air

pressure loss is shown on dash

gauge(s). Pressure loss shown on

gauges is caused by service brake

system or component leakage.

Pressure loss NOT SHOWN

on gauges is caused by supply

system or component leakage.

(continued)

6. With gauge installed at RES port of governor, pressure should

not drop below ”Cut-In” pressure at the onset of the compressor

“Unloaded” cycle. If pressure drops, check for “kinks” or

restrictions in line connected to RES port. Line connected to

RES port on governor must be same diameter, or preferably

larger than, lines connected to UNL port(s) on governor.

B. Leaking purge valve housing

assembly and/or o-rings in air

dryer end cover.

B. With the supply port open to atmosphere, apply 120 psi at the

control port. Apply a soap solution to the supply port and exhaust

port (purge valve seat area). Permissible leakage - 1" bubble in

5 seconds.

C. Holset

®

“E” type compressor.

C. Test the Holset

®

E Compressor unloader system with feedback

line and check valve for proper operation. Make certain Holset

ECON is not in use with the drop-in version of the air dryer, if

so, remove and retest.

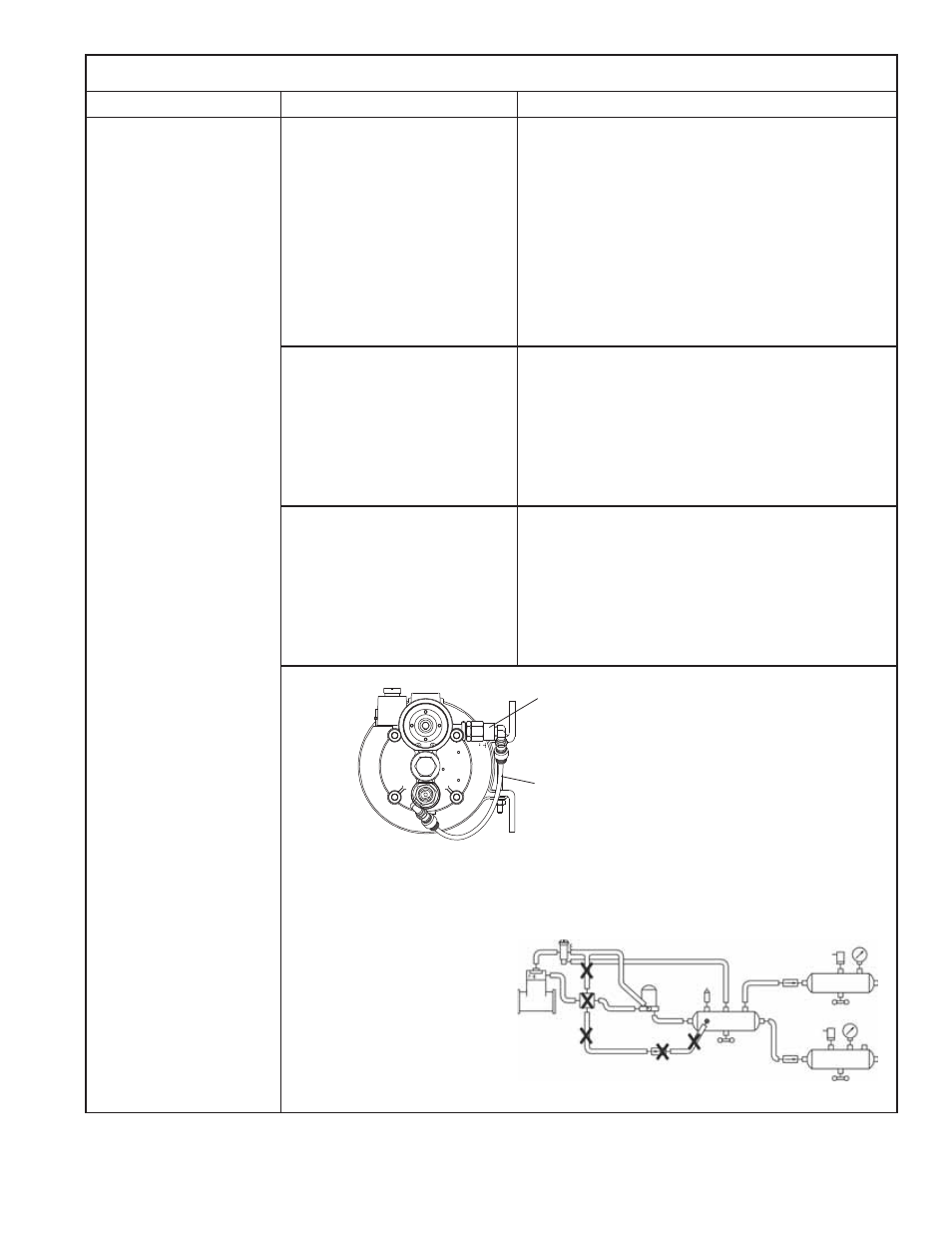

When installing a Bendix Drop-In air dryer in a system equipped

with a Holset E or QE compressor, remove the Holset ECON valve

along with its feedback and governor control line.

Typical Drop-In Air Dryer End Cover

Check Valve

Feedback Line