Burnham LE L7248 User Manual

Page 8

8

8.

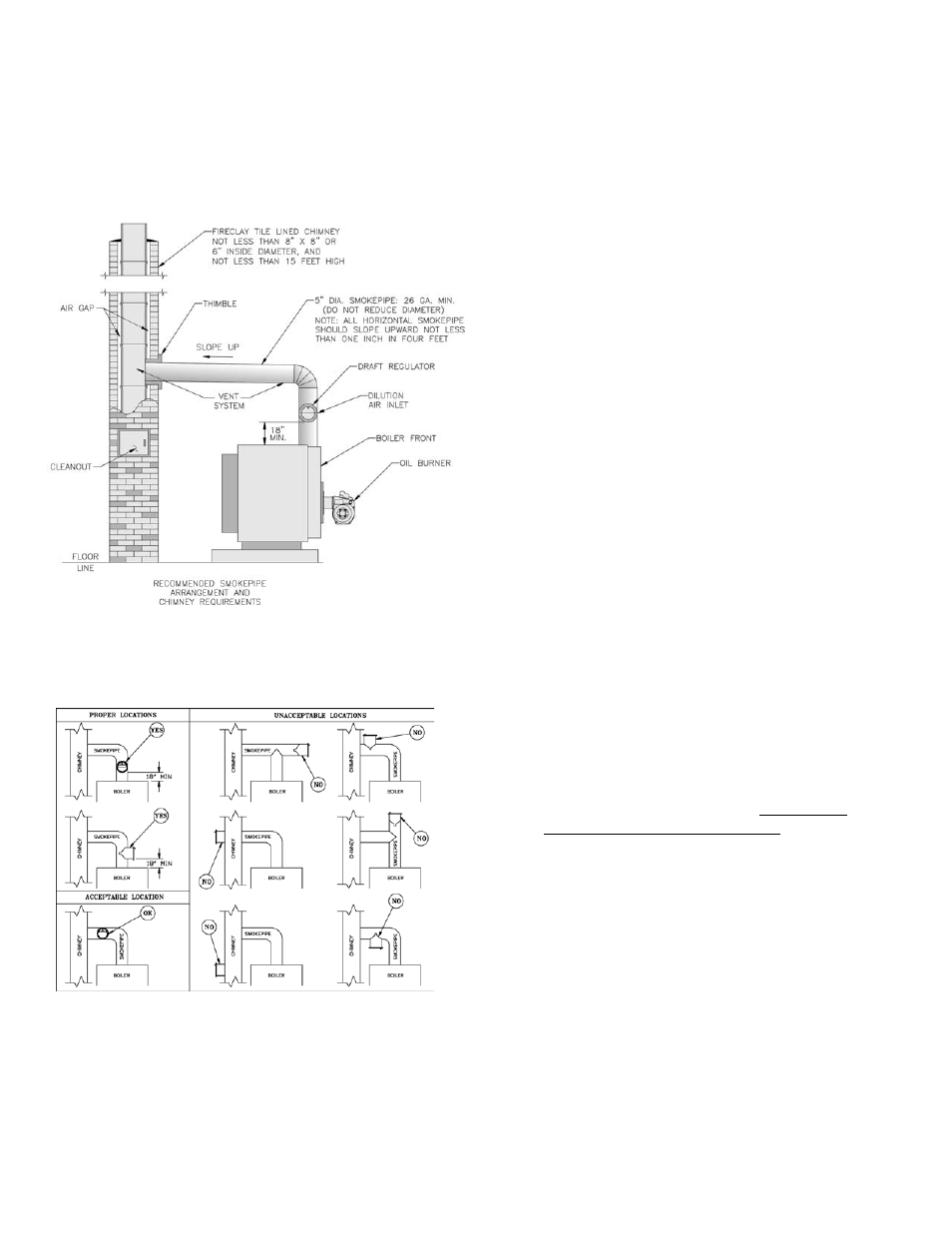

INSTALL SMOKEPIPE — The LE should be vented

into a fireclay tile-lined masonry chimney or a chimney

constructed from Type L Vent or a factory built

chimney that complies with the Type HT requirement,

of UL103. The chimney and vent pipe shall have a

sufficient draft at all times, to assure safe proper

operation of the boiler. See Figure 7 for recommended

installation.

Figure 8

Figure

a home without insulation or storm windows. With

increasing fuel prices that home probably has been

insulated and fitted with storm windows so that the

heat loss of the home has been reduced. This

requires less fuel to be burned and sends less heat

up the chimney.

A new boiler probably has a higher efficiency than

the boiler being replaced. That probably means that

the stack temperature from the new boiler will be

lower than that from the old boiler and with less

room air being drawn up the chimney to dilute the

stack gases. The combination of a large uninsulated

chimney, reduced firing rate, reduced firing time,

lower stack temperature and less dilution air can, in

some cases, contribute to the condensing of small

amounts of water vapor in the chimney. Such

condensation, when it occurs, can cause chimney

deterioration. In extreme cases, condensed water

may be visible on the outside of the breeching or

chimney. In those extreme cases, the chimney may

have to be lined to insulate the chimney and thus

prevent the condensation. The addition of dilution

air into the chimney may assist in drying the

chimney interior surfaces.

C. Heat extractors mounted into the breeching are not

recommended.

9.

INSTALL ELECTRIC WIRING

A. Follow the National Electrical Code and local

regulations. A separate electrical circuit must be run

from the main electrical service with an over-

current device/disconnect in the circuit. A service

switch is recommended and may be required by

some local jurisdictions. Wiring should conform to

Figures 11A, 11B and 11C.

B. CANADA — Refer to CSA standard C22.2 Part 1,

1990, Electrical Features of Fuel Burning Equip-

ment (Gas and Oil).

C. If boiler is installed in Canada, a blocked vent safety

switch must be installed. Refer to Blocked Vent

Safety Switch Instruction Supplement provided

with boiler (Canada only).

10.

FUEL UNITS AND OIL LINES

Use flexible oil line(s) so that Swing Door can be

opened without disconnecting oil supply.

A supply line fuel oil filter is recommended as a

minimum for all firing rates but a pleated paper fuel oil

filter is recommended for the lowest (.6 GPH) firing

rate application to prevent nozzle fouling.

SINGLE-PIPE OIL LINES — Standard burners are

provided with single-stage 3450 rpm fuel units with the

by-pass plug removed for single-pipe installations.

The single-stage fuel unit may be installed single-pipe

with gravity feed or lift. Maximum allowable lift is 8

feet. See Figure 9.

A. Install the draft regulator following the instructions

furnished with the regulator. See Figure 8 for

alternate draft regulator locations.

B. Consider the chimney overall. Chimneys that have a

high heat loss may become less suitable as the heat

loss of the home goes down and the efficiency of

the boiler installed goes up. Most homes have a

chimney appropriate for the fuel and the era in

which the home was built. That may have been a

coal fired or an inefficient oil fired boiler built into