Pad cleaning, Acuum – Wood’s Powr-Grip P11104DC2 User Manual

Page 31

Rev 0.3/11-13

29

P1-DC2: #35112

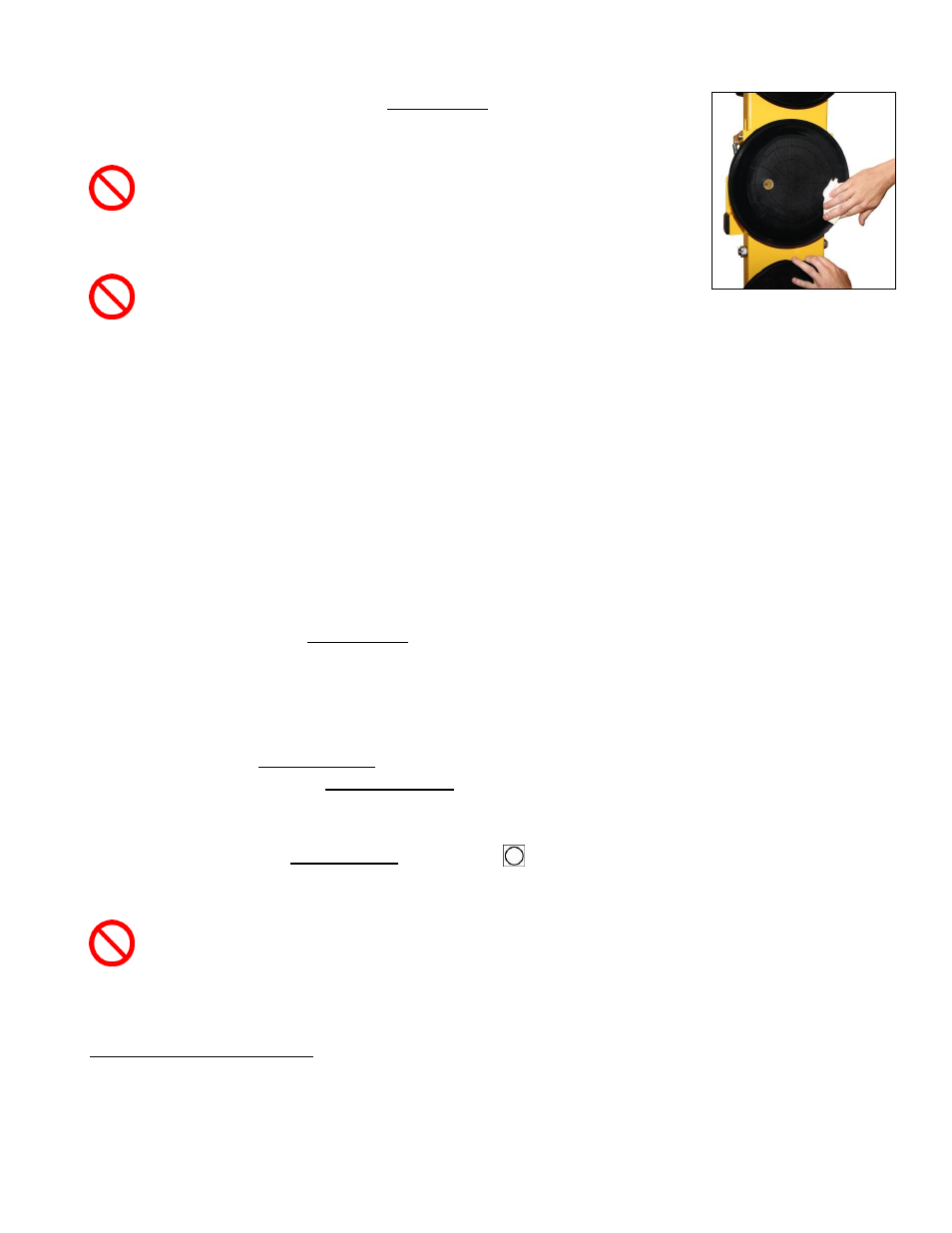

Pad Cleaning

1) Regularly clean the face of each vacuum pad as shown, to remove oil,

dust and any other contaminates. Acceptable cleaning agents include

soapy water and other mild cleansers.

Never use solvents, gasoline or other harsh chemicals to

clean vacuum pad.

Solvents, petroleum-based products (including kerosene, gasoline and

diesel fuel) or any harsh chemicals can damage vacuum pads.

Never use unauthorized rubber conditioners on vacuum

pad.

Most rubber conditioners, such as ArmorAll

®

, can leave a hazardous film on vacuum pads,

which could compromise lifting capacity and/or create a hazard to the operator or others.

2) Make sure to prevent liquid from contaminating the vacuum system through the suction hole

on the pad face.

3) Use a clean sponge or lint-free cloth to apply an authorized cleanser and wipe the pad face

clean.

25

4) Allow the pad to dry completely before using the lifter.

V

ACUUM

T

EST

Test the vacuum system for leakage routinely (see preceding I

NSPECTION

and T

ESTING

S

CHEDULES

).

1) Clean the face of each vacuum pad (see V

ACUUM

P

AD

M

AINTENANCE

: Pad Cleaning).

2) Use a test load with a weight equal to the Maximum Load Capacity (see SPECIFICATIONS)

and a clean, smooth, nonporous surface, as well as other appropriate L

OAD

C

HARACTERISTICS

(see INTENDED USE).

26

3) Apply the lifter to the test load as previously directed (see OPERATION: T

O

A

PPLY THE

P

ADS TO A

L

OAD

). After the vacuum pump stops running, the vacuum level should register above 16" Hg

[-54 kPa] on each of the vacuum gauges (if not, see DIGITAL VACUUM SWITCH

ADJUSTMENT in

SERVICE MANUAL

for details).

4) Raise the load a minimal distance, to make sure that the vacuum pads are loaded to capacity,

and place the lifter's power switch in the OFF ( ) position.

5) Monitor the vacuum gauges:

The vacuum level should not decrease by more than 4" Hg

[-14 kPa] in 5 minutes.

Never use a lifter that has failed the V

ACUUM

T

EST

.

Correct any deficiency in the vacuum system before using the lifter.

25

A toothbrush (or similar brush with bristles

that do not harm rubber) may be used to remove contaminates clinging to sealing

edges. If these cleaning methods are not successful, contact Wood’s Powr-Grip or an authorized dealer for assistance.

26

The load surface should be flat or possess no more curvature than the lifter is designed for (if any).