Weidmuller G168 Ultra SlimPak User Manual

Page 3

Unless otherwise specified, the factory presets the Model G168 as follows:

Input: Voltage

Range: 0-500mVac

Output: Dual, SPDT

Trip: A:HI, B:LO

Failsafe: No

Deadband: A, B: 0.25%

The DC power input accepts any DC source between 9 and 30V, typically a 12V or 24Vdc source is used.

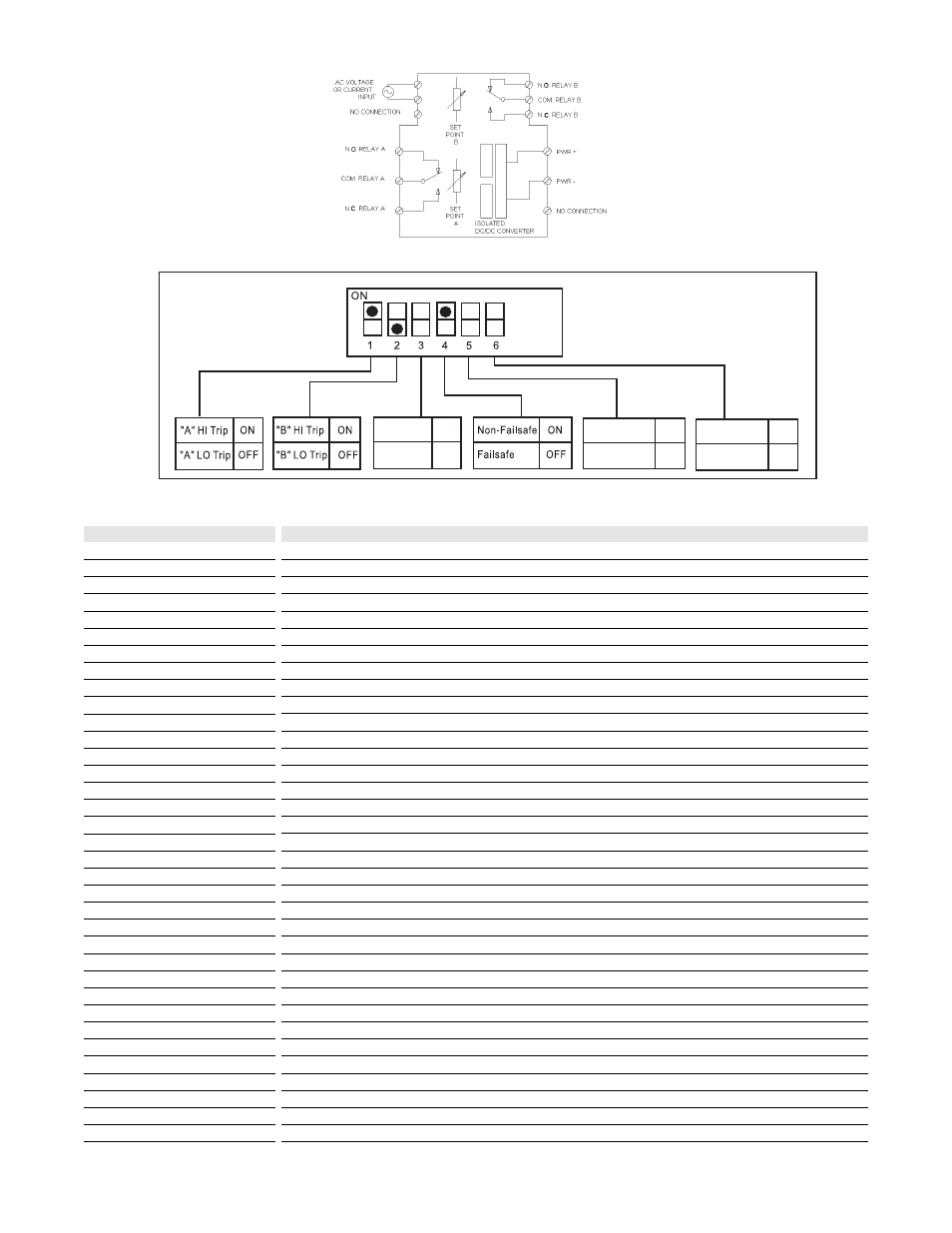

For other I/O ranges, refer to Table 1 and Figure 4 to reconfigure switches SW1 and SW2 for the desired

input type, range and function.

Do not attempt to change any switch settings with power applied. Severe damage will result!

1. With DC power off, position input switch "SW1-9,10" for voltage or current.

2. Set position 1 through position 8 of input range switch "SW1" for the desired input range (see Table 1).

3. Set position 1 and 2 of function switch "SW2" to ON for a HI trip setpoint or OFF for a LO trip

(see Figure 4).

4. Set position 4 of function switch "SW2" to ON for non-failsafe operation or OFF for failsafe operation (e.g.

alarm trips when power fails).

1. After configuring the dip switches, connect the input to a calibrated AC source and apply power. Refer to

the terminal wiring diagram.

NOTE: To maximize thermal stability, final calibration should be performed in the operation installation,

allowing approximately 1 to 2 hours for warm up and thermal equilibrium of the system.

2. Setpoint: set deadband at its minimum (fully counter-clockwise) before adjusting the setpoint. With the

desired trip voltage or current input applied, adjust setpoint until the relay trips. For HI trip calibration,

start with the setpoint above the desired trip (full clockwise). For LO trip calibration, start below the desired

trip (full counter-clockwise).

3. Deadband: Set deadband to its minimum (fully counter-clockwise). Set the setpoint to desired trip. Adjust

voltage/current input until relay trips. Readjust deadband to 5% (fully clockwise). Set voltage/current input

signal to desired deadband position. Slowly adjust deadband until relay untrips.

When switching inductive loads, maximum relay life and transient EMI suppression is achieved using

external protection (see Figures 2 and 3). Place all protection devices directly across the load and

minimize all lead lengths. For AC inductive loads, place a properly rated MOV across the load in parallel with

a series RC snubber. Use a 0.01 to 0.1

HF pulse film capacitor (foil polypropylene recommended) of

sufficient voltage, and a 47

M, 1/2W carbon resistor. For DC inductive loads, place a diode across the load

(PRV>DC supply, 1N4006 recommended) with (+) to cathode and (-) to anode (the RC snubber is an

optional enhancement).

Configuration

WARNING:

Calibration

Relay Protection and EMI

Suppression

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

Figure 4: G168 function selection switch-settings (SW4) factory default settings