General use, Rolling flat joints – TapeTech 12TT Monster Mesh Taper User Manual

Page 3

Page 3 of 4 ©2001 Ames Taping Tool Systems

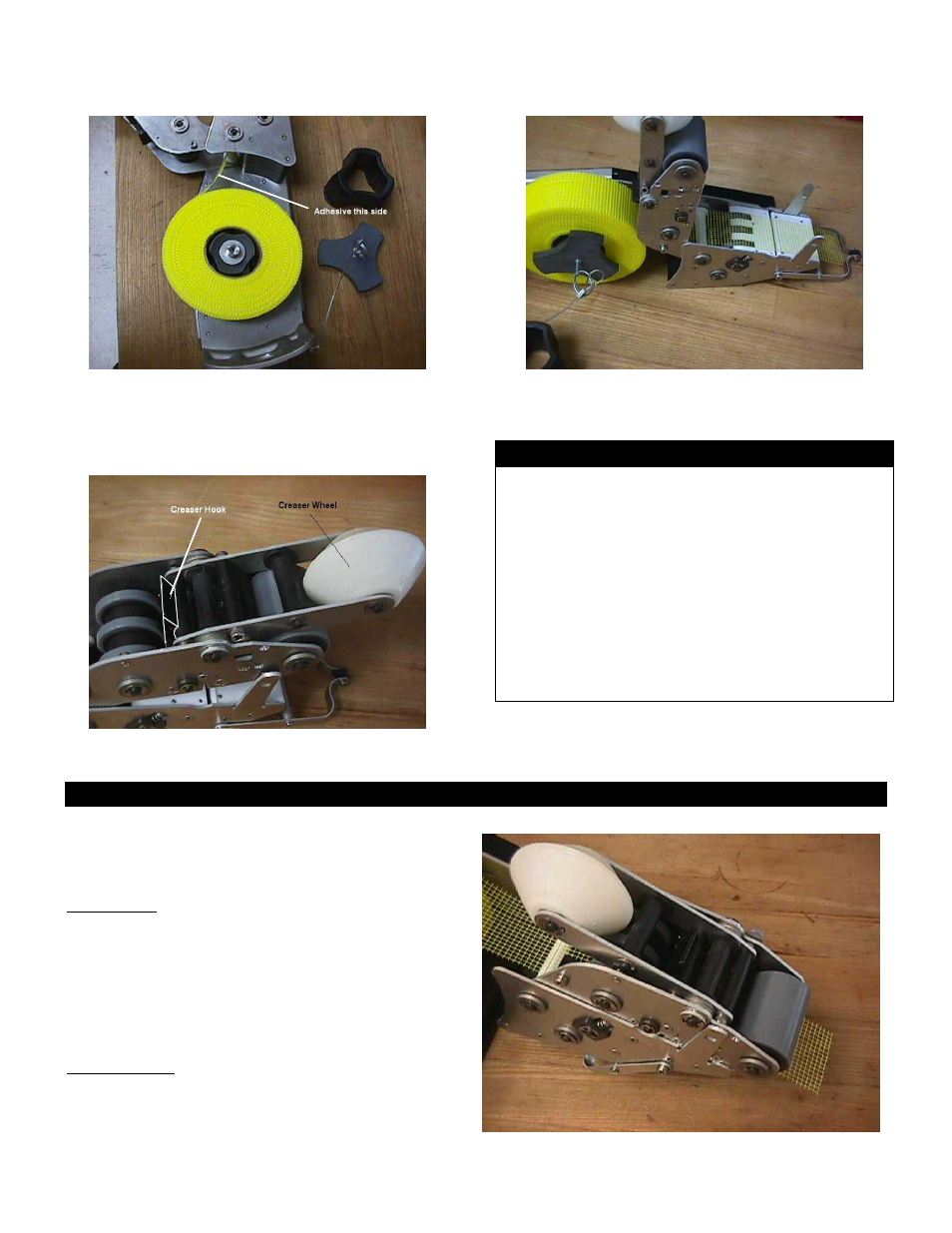

3. Install tape with wrap in clockwise direction –

adhesive side to Main Chassis.

4. Install

Tape

Retainer.

5. Ensure white Creaser Wheel is in forward (toward

Front Roller) position and open Jaw Assembly.

6. Pull tape between Jaw and Main Chassis until it

protrudes approximately 1” past end of Chassis.

7. Close Jaw Assembly.

GENERAL USE

1. For right-handed individuals: place the left hand on

the Control Tube and the right hand between the 2,

black grip rings on the rear of the Main Tube. This

may be reversed for left-handed users.

2. Advance tape by pushing forward on the Control

Tube until mechanism stops. Return Control Tube

to “neutral” position.

3. Cut tape by pulling back on the Control Tube until

mechanism stops. Return Control Tube to

“neutral” position.

4. Do not attempt to roll tape while cutting. This WILL

cause Taper to jam.

ROLLING FLAT JOINTS

Ensure Creaser Wheel is in stowed position. Lock in

place by pulling forward on Creaser Hook. The Hook

should snap into place.

For verticals:

1. Advance tape once. Place Front Roller firmly against

wall and roll upward (tape spool should be to the left of

the operator). Maintain a 45° to 90° angle between

Taper and wall. This prevents Creaser Wheel from

contacting wall.

2. Approximately 4” from the end of the seam stop rolling

and cut tape. Roll out remainder of tape.

For horizontals:

1. Same as above. It is recommended that taping be

done from left to right (with the tape roll on top). This

allows tape to seat better on Tape Spool.