Coil static pressure drop (in. wc) – Bryant CK3B User Manual

Page 5

—5—

CFM

— Cubic Ft per Minute

EWB

— Entering Wet Bulb (

°

F)

LWB

— Leaving Wet Bulb (

°

F)

TC

— Total Cooling Capacity 1000 Btuh

SHC

— Total Sensible Capacity 1000 Btuh

BF

— Bypass Factor

MBH

— 1000 Btuh

NOTES:

1. Contact manufacturer for cooling capacities at conditions other than

shown in table.

2. Formulas:

Leaving db = entering db —

Leaving wb = wb corresponding to enthalpy of air leaving coil (h

LWB

)

h

LWB

= h

EWB

—

where h

EWB

= enthalpy of air entering coil.

3. Direct interpolation is permissible. Do not extrapolate.

4. SHC is based on 80

°

F db temperature of air entering coil.

Below 80

°

F db, subtract (Correction Factor x CFM) from SHC.

Above 80

°

F db, add (Correction Factor x CFM) to SHC.

5. All data points are based on 10

°

F superheat leaving coil.

6. Bypass Factor = 0 indicates no psychometric solution. Use bypass

factor of next lower EWB for approximation.

Interpolation is permissible.

Correction Factor = 1.09 x (1 – BF) x (db – 80)

sensible heat cap.

1.09 x CFM

total capacity (Btuh)

4.5 x CFM

BYPASS

FACTOR

ENTERING AIR DRY BULB TEMPERATURE (

°

F)

79

78

77

76

75

Under 75

81

82

83

84

84

Over 85

Correction Factor

0.10

0.98

1.96

2.94

3.92

4.91

Use formula

shown below

0.20

0.87

1.74

2.62

3.49

4.36

0.30

0.76

1.53

2.29

3.05

3.82

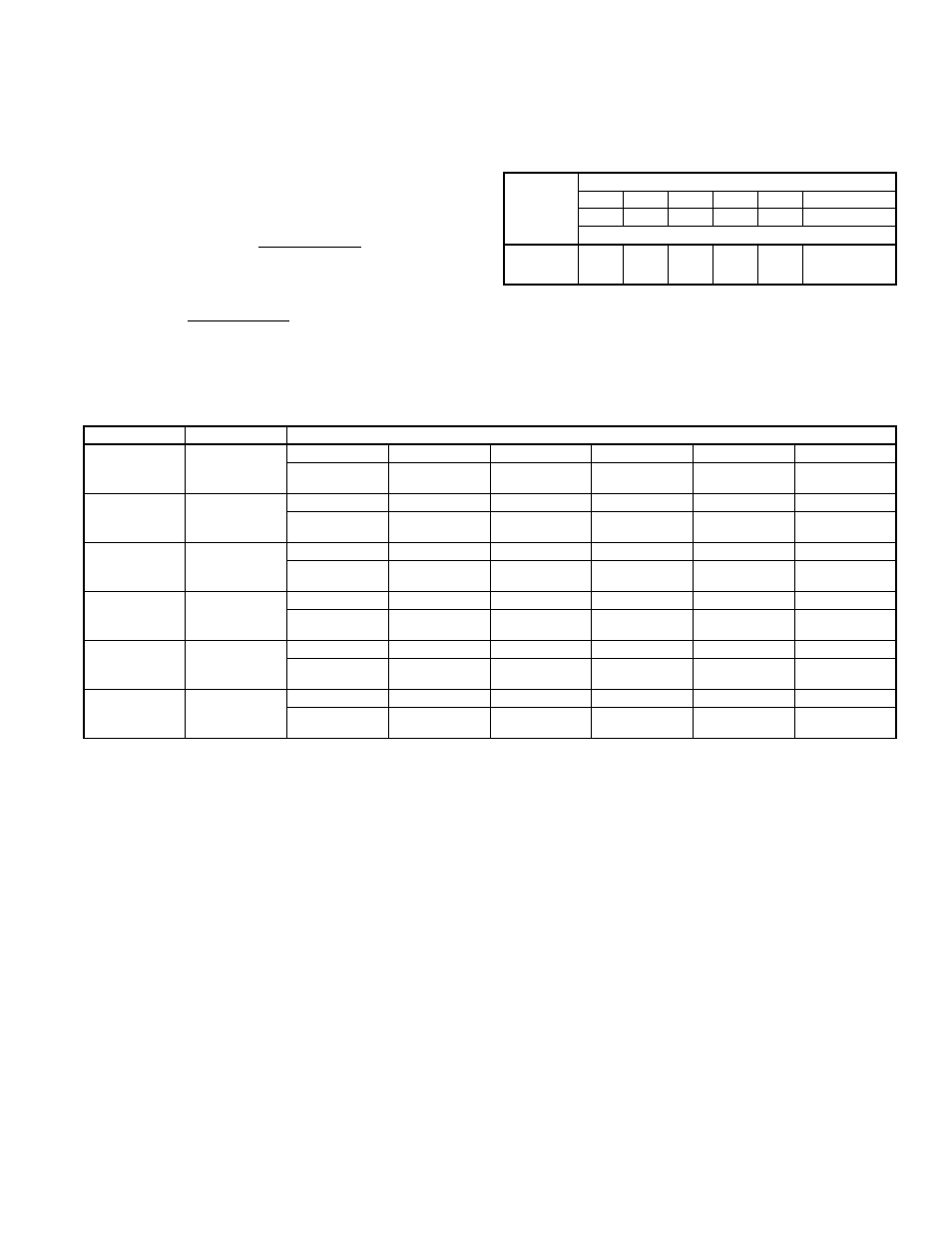

COIL STATIC PRESSURE DROP (In. WC)

UNIT SIZE

BULB

AIR QUANTITY (CFM)

A024

600

700

800

900

—

—

WET

0.08

0.10

0.13

0.16

—

—

DRY

0.06

0.08

0.11

0.13

—

—

A030

700

800

900

1000

1100

—

WET

0.08

0.12

0.15

0.19

0.23

—

DRY

0.08

0.10

0.14

0.17

0.21

—

A036

900

1000

1100

1200

1300

—

WET

0.16

0.19

0.23

0.27

0.32

—

DRY

0.13

0.17

0.21

0.25

0.29

—

A042

1000

1100

1200

1300

1400

—

WET

0.18

0.21

0.24

0.27

0.31

—

DRY

0.14

0.17

0.20

0.23

0.26

—

A048

1300

1400

1500

1600

1700

—

WET

0.19

0.22

0.25

0.28

0.31

—

DRY

0.18

0.21

0.24

0.27

0.30

—

A060

1600

1700

1800

1900

2000

2100

WET

0.19

0.22

0.24

0.26

0.28

0.30

DRY

0.18

0.20

0.21

0.24

0.26

0.28