Integral system – Sportsliter Solutions Integral System User Manual

Page 9

8

INTEGRAL SYSTEM

INSTALLATION

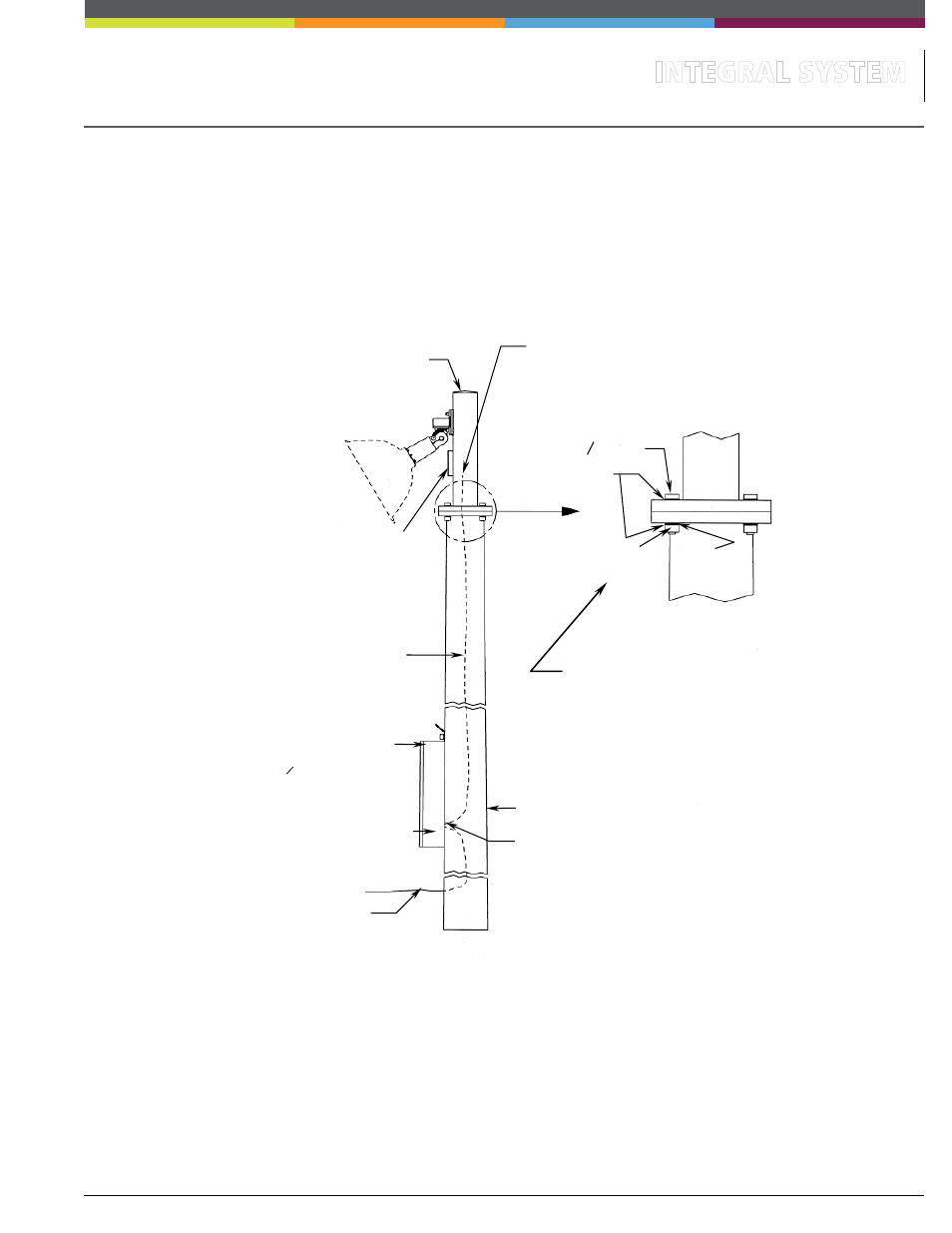

CAP PLATE COMPONENT MOUNTING TO STEEL OR CONCRETE POLES (FIG. 11)

ATTACH WIRING HARNESS STRAIN

RELIF TO SUPPORT INSIDE

CROSSARM ASSEMBLY

CROSSARM MOUNTING HARDWARE

SHIPPED WITH CROSSARM ASSEMBLY

¾” O BOLT (4)

FLAT WASHERS

NUT

LOCK

WASHER

CROSSARM MTG. DETAIL

NOTE: TIGHTEN NUTS ON MTG. DETAIL

TO 100 ft/lbs. MINIMUM

CROSSARM ASSEMBLY

FIELD SIDE

HANDHOLE

WIRING HARNESS

CONNECT TO PLUG IN

REMOTE BALLAST BOX

AND JUNCTION BOX AT

TOP

SEAL ANY OPENINGS AROUND

BOTTOM ATTACHMENT POINT

WITH SILICONE SEALANT

SUPPLY WIRING

(BY OTHERS)

REMOTE BALLAST BOX

SECURE TO POLE WITH

¾” O BOLTS (2) AND

WASHERS SHIPPED WITH

BOX. (TIGHTEN TO 20 ft/lbs.

MAX)

STEEL OR CONCRETE POLE

GASKET BETWEEN POLE & REMOTE

BALLAST BOX FOR WATERTHGHT SEAL

FOR DETAILED INSTALLATION INSTRUCTIONS

FOR THE REMOTE BAX, SEE THE INSTRUCTION

SHEET INCLUDED WITH EACH.

CAP PLATE COMPONENT MOUNTING TO STEEL OR CONCRETE POLES (FIG. 11)

ATTACH WIRING HARNESS STRAIN

RELIF TO SUPPORT INSIDE

CROSSARM ASSEMBLY

CROSSARM MOUNTING HARDWARE

SHIPPED WITH CROSSARM ASSEMBLY

¾” O BOLT (4)

FLAT WASHERS

NUT

LOCK

WASHER

CROSSARM MTG. DETAIL

NOTE: TIGHTEN NUTS ON MTG. DETAIL

TO 100 ft/lbs. MINIMUM

CROSSARM ASSEMBLY

FIELD SIDE

HANDHOLE

WIRING HARNESS

CONNECT TO PLUG IN

REMOTE BALLAST BOX

AND JUNCTION BOX AT

TOP

SEAL ANY OPENINGS AROUND

BOTTOM ATTACHMENT POINT

WITH SILICONE SEALANT

SUPPLY WIRING

(BY OTHERS)

REMOTE BALLAST BOX

SECURE TO POLE WITH

¾” O BOLTS (2) AND

WASHERS SHIPPED WITH

BOX. (TIGHTEN TO 20 ft/lbs.

MAX)

STEEL OR CONCRETE POLE

GASKET BETWEEN POLE & REMOTE

BALLAST BOX FOR WATERTHGHT SEAL

FOR DETAILED INSTALLATION INSTRUCTIONS

FOR THE REMOTE BAX, SEE THE INSTRUCTION

SHEET INCLUDED WITH EACH.