Schwank IT(U) User Manual

Page 11

GP-MSEM-BX-06A

SEM(U) / IT(U) Manual

RD: Aug 2006

RL: 06A

KH

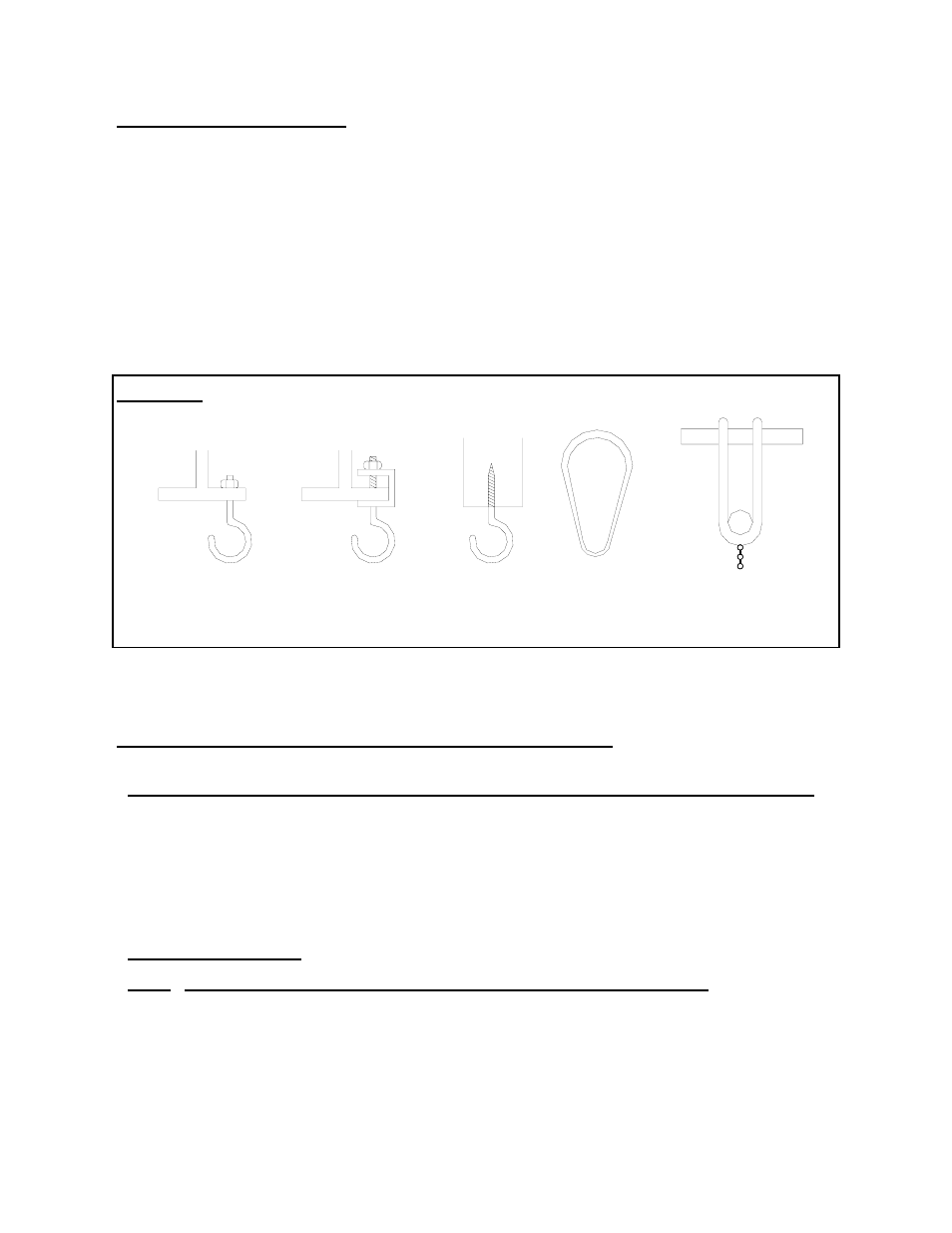

8. SUSPENSION SYSTEM

The system configuration and available support locations must be considered in order to lo-

cate the radiant tubes correctly. Labour and material can be reduced by locating (system con-

figuration permitting) directly under structural members such as joists, steel or wood beams,

etc.

Chain is recommended for hanging the tube system, connecting the hangers to beam support

as illustrated in FIGURE 3 (below). To support burner and keep it level, a separate suspension

chain must be attached to the eye hook at flange end of burner angled slightly back over

burner, FIGURE 4A & 4B (below). This will permit normal expansion and contraction of the

tube system. (If rigid devices such as rods are used in place of chain, swing joints or other

means of sufficient length must be provided to compensate for expansion.)

FIGURE 3 SUGGESTED MOUNTING HARDWARE

EYE BOLT THROUGH

HOLE IN BEAM

BEAM CLAMP

WITH EYE SCREW

EYE

SCREW

PIPE RING

OR CLEVIS

BAR-JOIST

CLAMP

Page 7

9. SEM / IT STRAIGHT TUBE SYSTEM ~ BURNER AND TUBE INSTALLATION

SEM / IT: With all hangers aligned and suspended at the same height, insert first aluminized

tube section, through 4" hole into first two wire hangers. SEE FIGURE 4A.

Bolt burner to flange on first tube section, SEE FIGURE 6. Subsequent lengths of tube can

then be installed, by joining them together one inside the other and locking the joints using

the aluminized steel coupler. SEE FIGURE 7.

IMPORTANT NOTE: Models with inputs 175,000 & 200,000 refer to section 9C.

Note: Turbulators are ALWAYS installed at the vent end of the heater .

9 INSTALLATION OF HANGERS, TUBES AND BURNER