Important: * (s – Schwank IT(U) User Manual

Page 10

GP-MSEM-BX-06A

SEM(U) / IT(U) Manual

RD: Aug 2006

RL: 06A

KH

7. SYSTEMS INCORPORATING 90° ELBOWS

The 90° elbows are shipped as a kit with one

clamp and two end caps to close off the re-

flector ends each side of the elbow (s). The

Reflectors must be secured with four screws

to each of the end caps. (see FIG 10)

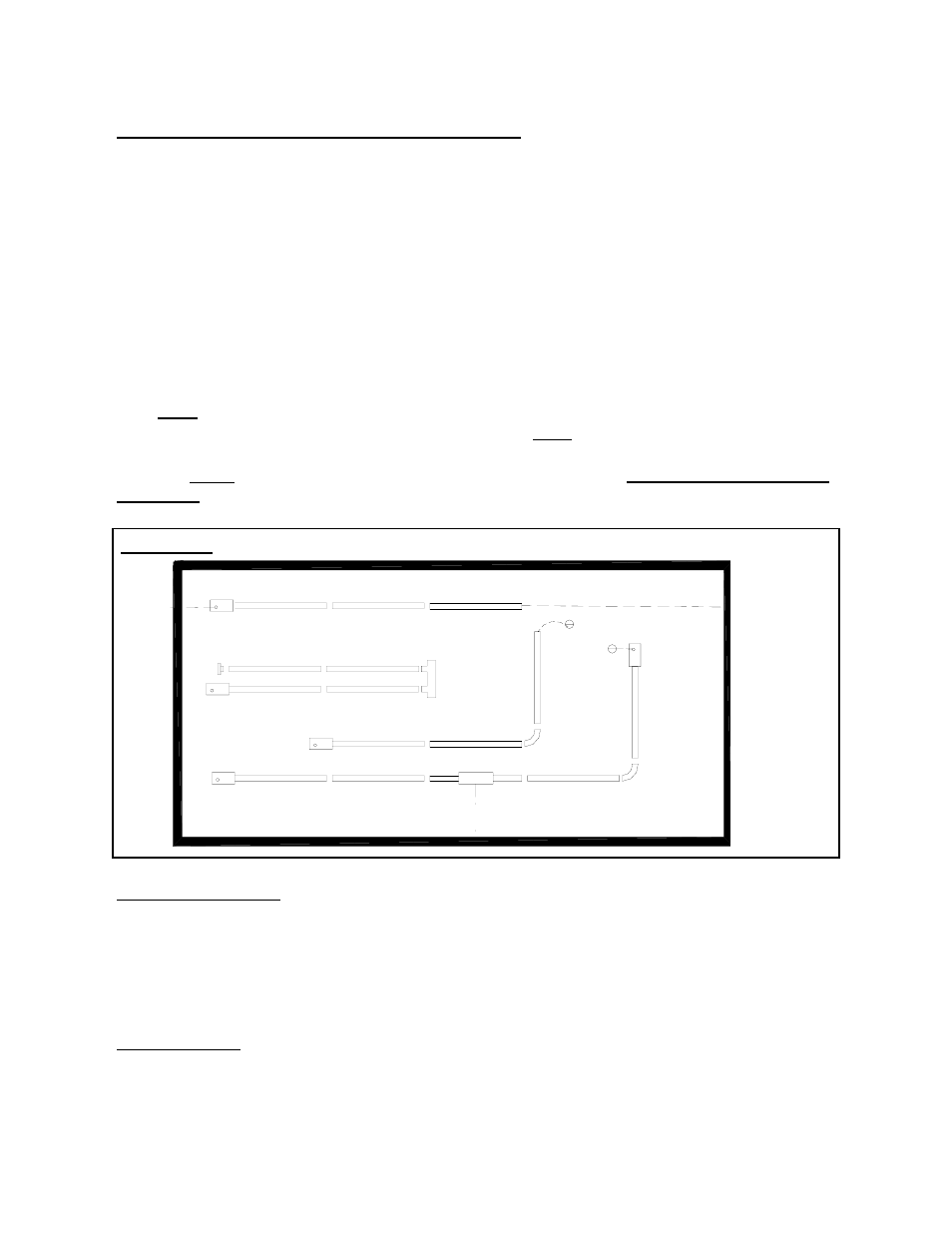

FIGURE 2 SYSTEM CONFIGURATIONS

System Configuration

1

Straight line

2

“U” tube with Turn Box

3

“L” tube with 90

0

elbow kit

4

Twinned tubes into common TEE flue vent

* Note: Both heaters must be connected

with a single common thermostat

Venting Options

A Flue vent through wall 4”

B Flue vent through wall or roof 6”

C Flue vent through roof

D Flue vent into building, exhaust fan inter

locked with heater

E Combustion air intake from outside

through wall.

F Combustion air intake from outside

through roof

G Combustion air intake from inside

building

IMPORTANT: * (S

TRAIGHT

T

UBE

M

ODEL

O

NLY

) *

E

A

G

4

3

G

G

D

2

1

F

C

Model SEM / IT 100 x 20’ must be installed as a “straight system” with no elbows al-

lowed at the 10’ location. On Models SEM / IT, 175 a minimum of 30´ of straight radiant

tube must be connected to the burner before any elbow. On Models SEM / IT 155, 130,

and 110 a minimum of 20´ of straight radiant tube must be connected to the burner be-

fore any elbow. And on Models SEM / IT 80 and 60, a minimum of 10´ of straight radi-

ant tube must be connected to the burner before any elbows.

Not applicable to SEMU/

ITU model

The SEM / IT Series radiant tube heater can

be installed in configurations as illustrated in

Fig:2 (below) with a maximum of two 90°

elbows per heater. The use of radiant elbows

reduces the total maximum vent allowable.

(See SECTION: 11) Flue Venting.

Page 6

B