S&S Cycle USB Magneti Marelli Style VFI (Variable Fuel Injection) Module and ProTune II Software User Manual

Page 11

11

STOCK THROTTLE BODY SETUP PROCEDURE

S&S calibrations for use with stock Magneti Marelli® dual bore throttle bodies are setup to use the factory base Throttle Position Sensor (TPS)

calibration and hot and cold idle screw adjustments. If this module is being installed on a vehicle with a known good throttle body and TPS it is not

necessary to go through the base TPS setup procedure and you can skip to step 4 below for final idle speed adjustment. If the TPS has been replaced

or random adjustments made to the idle speed screws, the steps below can be used to get back to the base settings.

NOTE: Before performing these steps verify there are no intake manifold leaks and all vacuum caps are in place on the throttle body. Also, be sure that

throttle body components such as linkage arm and bearing are not worn and are in good, operable condition.

1- Base TPS Settings

a- Connect the PC to the VFI module and open ProTune II. With the bike turned on, open the Realtime ECM Gauges by selecting “Gauge” from

the top row of icons in ProTune II.

b- On the Realtime ECM Gauges screen, locate the gauge for “Throttle Voltage” and “Stepper Motor Position”. The “Stepper Motor Position”

gauge will display the number of steps the stepper motor (or Idle Air Control Motor) is currently holding the plates open and the “Throttle

Voltage” panel will display the current TPS voltage at that position.

c- Turn the vehicle’s ignition switch to off and observe the Stepper Motor Position. It will close to 0 steps and then open to 96 steps (1995-1998

models) or 100 steps (1999-2001 models). This is the stepper park position and is the starting point for setting the TPS base settings and

initial hot and cold idle screws.

d- After 15 seconds the VFI module will power down and communication will be lost. At this time, the Idle Air Control Motor (IAC) can be

disconnected. TPS base adjustments will be made with the IAC motor disconnected and the stepper at its park position.

e- Turn the key switch back to run and record the reading from the Throttle Voltage gauge. Remove the cold idle screw and record the TPS

voltage. Remove the hot idle screw and record the TPS voltage.

f- The Throttle Voltage will now show the base TPS voltage. This should read 0.19 to 0.21 volts. If the reading is outside of this range, verify the

throttle plates are shut by pressing on them gently. If the voltage remains outside of this range, adjust the TPS to correct. After adjustment

lightly open and close the plates a few times to ensure the TPS voltage will return to the proper setting.

g- Proceed to step 2 or 3 below based on your application.

2- Base Hot and Cold Idle Screw Settings for 1340cc (80”) and 1450 (88”)

a- Apply a small amount of blue Loctite® to the hot idle screw. Install the screw and adjust until the throttle voltage is showing 0.50 V (1995-

1998 models) or 0.54 V (1999-2001 models) when viewed on the Realtime ECM Gauges screen in ProTune II.

b- Lightly open and close throttle to verify setting.

c- Apply a small amount of blue Loctite to the cold idle screw. Install the screw and adjust until the throttle voltage is showing 0.61-0.64 V

(1995-1998 models) or 0.64-.068 V (1999-2001 models).

d- Lightly open and close throttle to verify setting.

e- Reconnect the plug to the IAC motor.

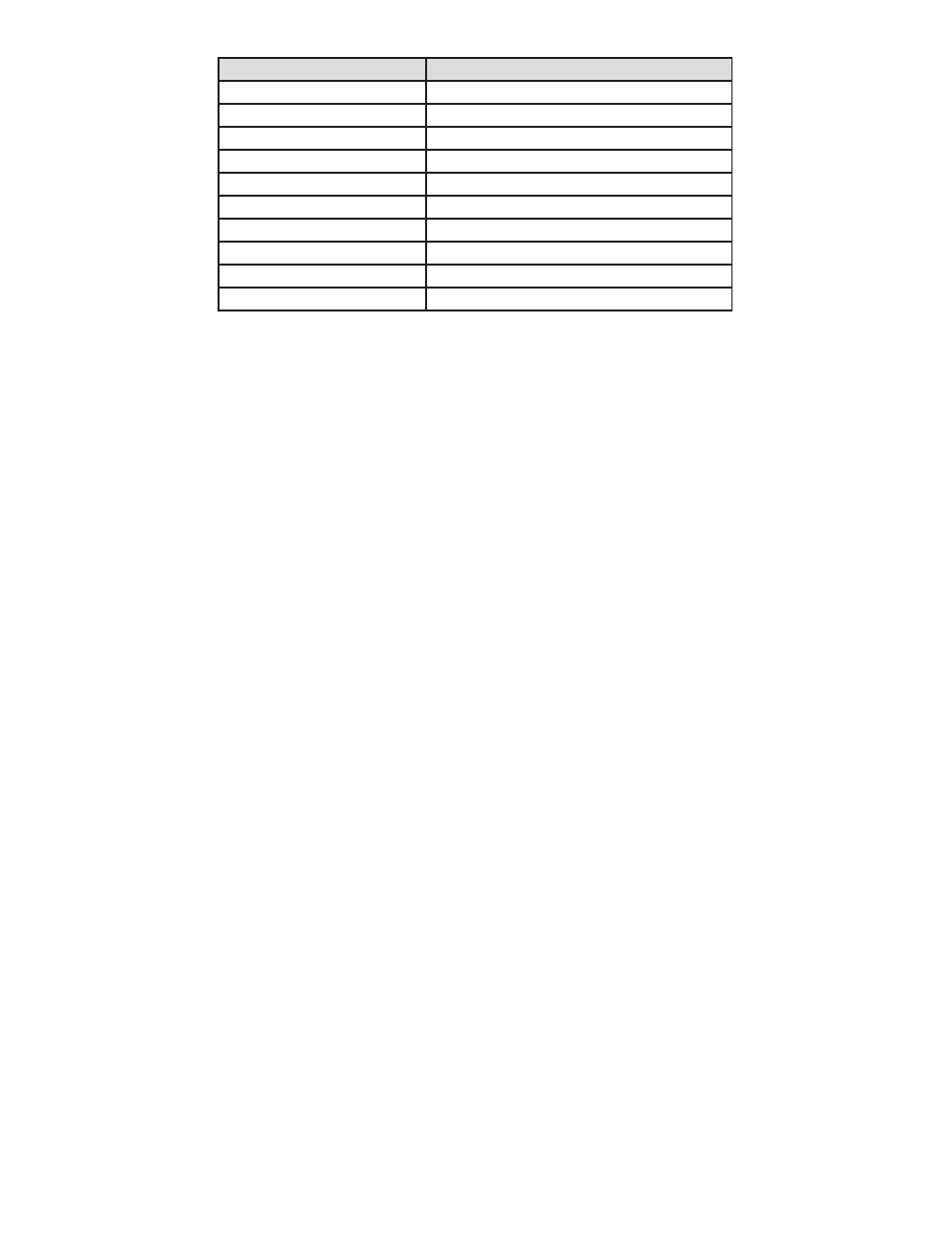

Check Engine Lamp Flash Code

Fault Condition

11

Throttle Position Sensor

12

Barometric Pressure Sensor

14

Engine Temperature Sensor

15

Intake Air Temperature Sensor

16

System Voltage (Battery) High

23

Front Injector

32

Rear Injector

34

Stepper Motor

42

Camshaft Position Sensor

54

EEPROM Error

Table 1