S&S Cycle Single Bore Induction Systems User Manual

Page 5

5

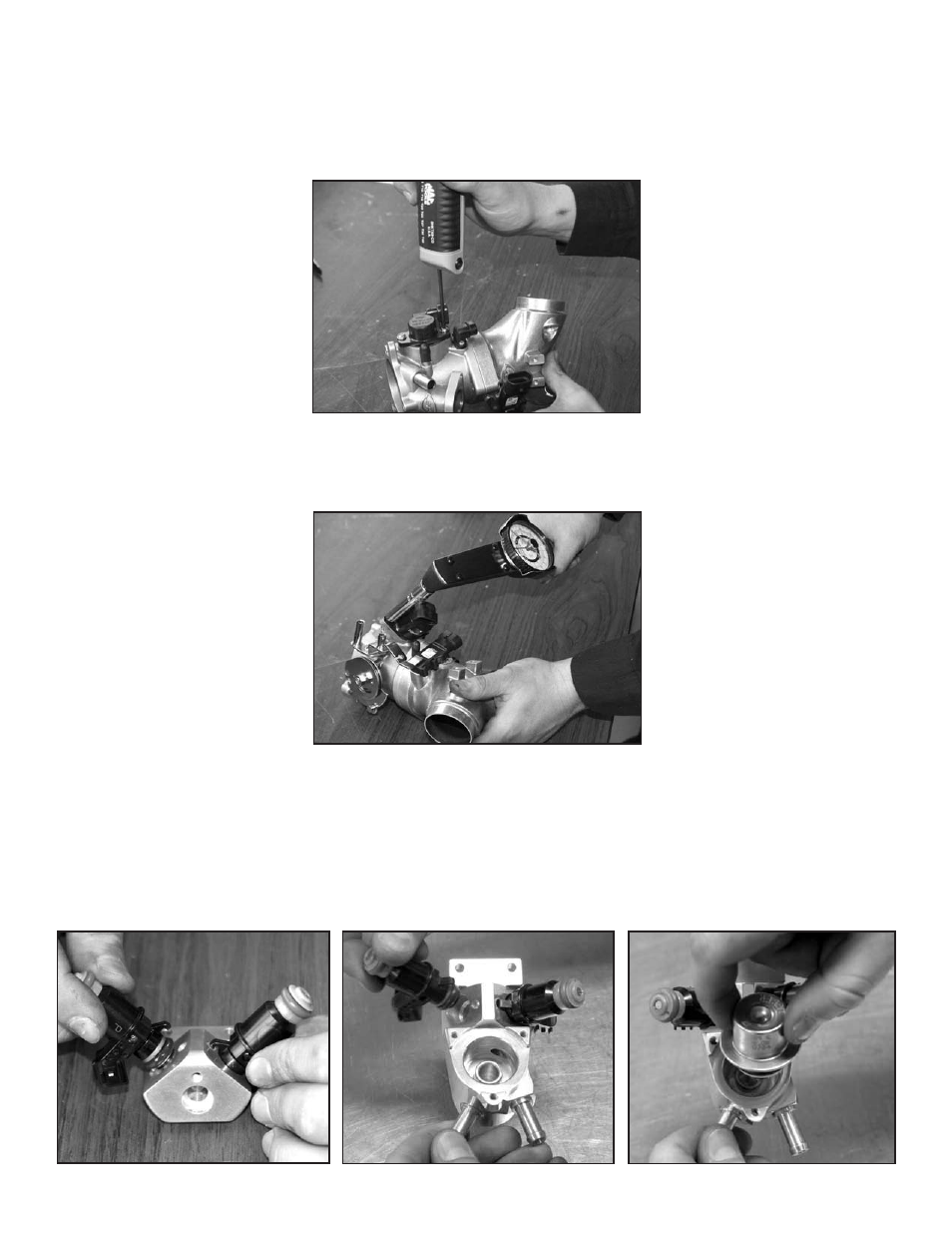

7- For 2001-'05, if the stock Throttle Position Sensor is used, put a 4mm flat washer on each T20 Torx button head M4 x .7 x 12mm screws, apply

some Loctite® 222 and torque screws to 18-23 in-lbs.

If a slotted sensor (55-5058) is used tighten as listed above. The screws and washers should be installed loose enough to allow rotation to

the correct position later.

For 1995-'01, use the stock slotted sensor or an S&S 55-5058.

8- Install the new O-ring on the IAC motor. Lubricate the OD of the O-ring with a light film of clean engine oil. Coat the threads of two 5/16” hex-head

1-24 x 1/2” screws with Loctite 222. Install the IAC motor with the connector pointing down and tighten the screws to 24-30 in-lbs.

9- Partially install the fuel injectors in the fuel rail. Be sure to orient the black O-rings to the rail and align the clocking tabs with their holes. It may

be helpful to lubricate the O-rings with clean engine oil. See Picture 9 and Picture 9a. Note, these are special O-rings that seal pressurized

gasoline. If you see one with damage or an abrasion—replace it immediately.

For 1995-'01, install the included 4-Bar (58 psi) pressure regulator or the stock 3-Bar (43 psi) unit if preferred. Use oil on the O-rings. Coat the 3

6-32 x 3/16" screws with Loctite 222. Install the screws and torque to 6 to 8 in-lbs. Note, a small clearance between the flange of the regulator and

screw heads may exist after they are torqued down. See Picture 9b.

Picture 7

Picture 8

Picture 9 (2001-'05)

Picture 9a (1995-'01)

Picture 9b