S&S Cycle Billet Oil Pump for Big Twin Engines User Manual

Page 2

2

INTRODUCTION

The billet oil pumps introduced by S&S® in early 2000 replace all cast and billet pumps used previously. Current pumps are similar to previous ones

with minor exceptions:

•

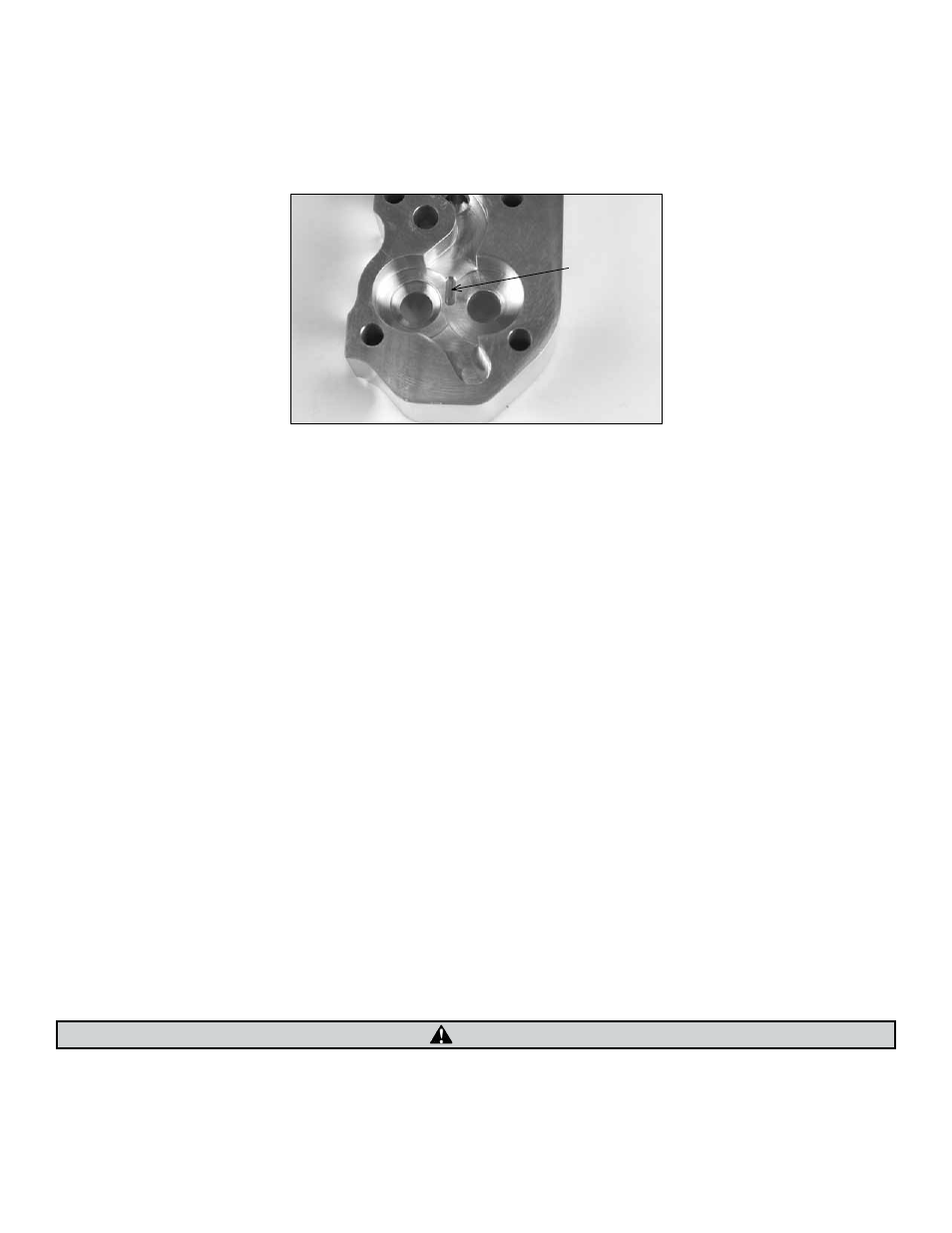

Gear cavities feature a small channel machined between gear pockets. Purpose of channel is to reduce oil-drag between drive and driven

gears. See Picture 1.

•

Pressure relief tower of new pumps is approximately .300" shorter than tower of earlier pumps.

•

New pump body eliminates gap between pump and crankcase where dirt and grime accumulate.

•

Part number can be found on bottom surface of oil pump body. In most applications a small mirror can be used to identify part number with

engine/oil pump still in frame. Previous oil pumps do not have part number on body or cover.

Current S&S oil pumps retain all features of previous pumps with exception of rear chain oiling, which has been eliminated. Current pump kits utilize

same gears, gaskets, seal, and other internal parts used in previous kits.

All S&S oil pumps provide same oil volume and pressure as 1973 and later Harley-Davidson® pumps if stock drive gears are used. S&S oil pump

supplies 33% more volume than cast iron pumps used on 1936-1967 big twins. An additional 25% increase can be achieved on engines manufactured

between 1939 and 1972 if optional S&S pinion and oil pump drive-shaft gears with 4:1 ratio are installed with S&S pump. (Stock pre-1973 ratio is 5:1.)

NOTE - S&S recommends optional pinion and oil pump drive shaft gears for most engines because increased oil supply is usually beneficial. However,

limited rate of oil return from top end may cause problems if later style drive gears are used in knucklehead. Even with standard gears, knucklehead engine

with S&S pump may require restriction of top end oil supply. This is discussed in more detail under NOTES on page 17.

OTHER IMPORTANT NOTES

•

Chrome Plating - S&S does not recommend chrome plating oil pump body or cover. Proper preparation for plating requires abrasive buffing compounds

which can plug critical passages and otherwise damage oil pump. Also, it is extremely difficult to chrome plate oil pump without altering critical

machined surfaces. Chrome in these areas can impair pump’s performance by altering critical operating tolerances. In addition, chrome may flake off

and cause damage to pump and engine.

•

Powdercoating - Subjecting heat-treated alloys such as those used in S&S oil pumps, crankcases, cylinders and heads to excessive heat can drastically

alter hardness, strength and other important properties. Degree to which these properties are altered depends upon temperatures reached and duration

of exposure. When powdercoating or otherwise processing alloy parts, S&S exposes them to a maximum temperature of 370° F for no longer than 20

minutes. Under no circumstances should parts be heated past 400° F. Owner assumes all risk and liability for altering oil pump except to insure correct

fit. See following note.

•

Increased wall thickness of some aftermarket crankcases may interfere with proper installation of oil pump. Procedure for insuring correct fit is described

in Installation section.

Plating or otherwise altering S&S oil pump or any component thereof may cause irreversible damage to pump and interfere with engine

lubrication. Damages caused by altered oil pump or component will not be covered under warranty.

Picture 1

CAUTION

Relief chanel