S&S Cycle Billet Oil Pump for Big Twin Engines User Manual

Page 17

17

•

Many solvents are flammable and potentially toxic. Read solvent manufacturerís instructions prior to use.

•

Compressed air is potentially harmful, especially to eyes and skin. Wear goggles and other protective clothing during use, and direct air

stream away from yourself and others nearby.

B. Disassemble, clean, and inspect oil pump, then reassemble pump dry, without lubrication. (Pump will be lubricated in final step.) Inspect

gaskets for loose bits of material that could dislodge and block oil passages.

C. Adjust primary chain oil supply (1936-1984 models with chain drive and dry clutch). Only oil pump bodies #31-6048 and #31-6049 andcover

#31-6059 have provision for primary chain oiling.

a. 1936-1964 models

1. Install 1⁄16 -27 pipe plug #50-8116 in hole #7 in top of cover.

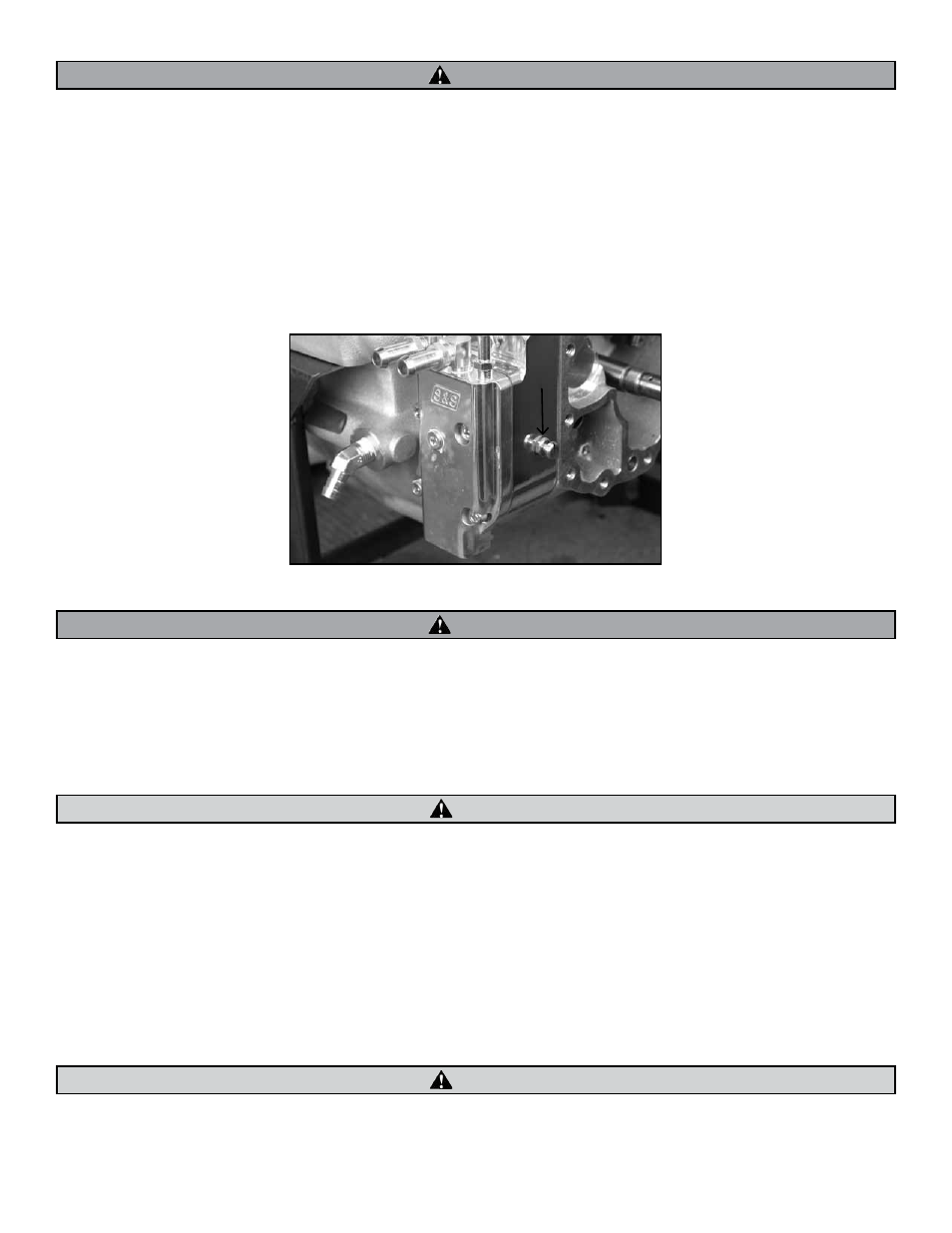

2. Install #31-6026 adjuster screw, #50-7008 brass washer, and #50-5000 lock nut into threaded hole in side of pump body. Gently

bottom screw three times to seat properly. See Picture 30.

WARNING

Picture 30

Chain oiler adjusting screw has tapered end and must be used. Substituting standard machine screw for tapered screw will result in large

oil loss out breather. Oil may contact rear brake and tire, resulting in possible loss of control of motorcycle and injury to rider and others.

3. Turn screw out 1⁄2 turn and tighten locknut against brass washer and body.

NOTE - After engine has been run, it may be necessary to adjust screw to achieve desired oil flow to primary chain. Final screw setting is usually closer to

fully closed position.

Overtightening screw may damage threads or adjusting screw seat in pump body.

b. 1965-1984 engines with primary chain drive and dry clutch

1. Install #50-8116 hose fitting in threaded hole #7 on top of pump cover.

2. Connect hose fitting #50-8116 in hole #7 to primary chain oil line.

3. For 1965-1972 engines using #31-6048 pump body, install #31-6026 adjuster screw, brass washer #50-7008, and lock nut #50-5000 into

threaded hole in side of pump body. See Picture 30. Gently bottom screw three times to seat screw. Turn screw out approximately

11⁄4 turns and tighten locknut against brass washer and oil pump body.

NOTE - Above setting should provide 1 to 13/4 oz: minute oil flow to primary chain @ 2500 RPM. This can be confirmed after engine has reached

operating temperature by disconnecting hose to primary chain, operating engine at 2500 RPM and measuring oil delivered into measuring container

during one minute.

Overtightening adjustment screw may damage oil pump body.

D. Rotate gears as preliminary check for bind, and to confirm that drive gear keys are properly installed.

WARNING

CAUTION

CAUTION