Caution, Caution warning caution – S&S Cycle Stroker Kits 106 for Harley-Davidson Twin Cam 88 Engines User Manual

Page 5

NOTES:

●

S&S

®

recommends at least .060” clearance around periphery

of valve.

●

S&S recommends at least .060” clearance between intake

valve and piston valve pocket recess, and .080” between

exhaust valve and piston valve pocket recess.

●

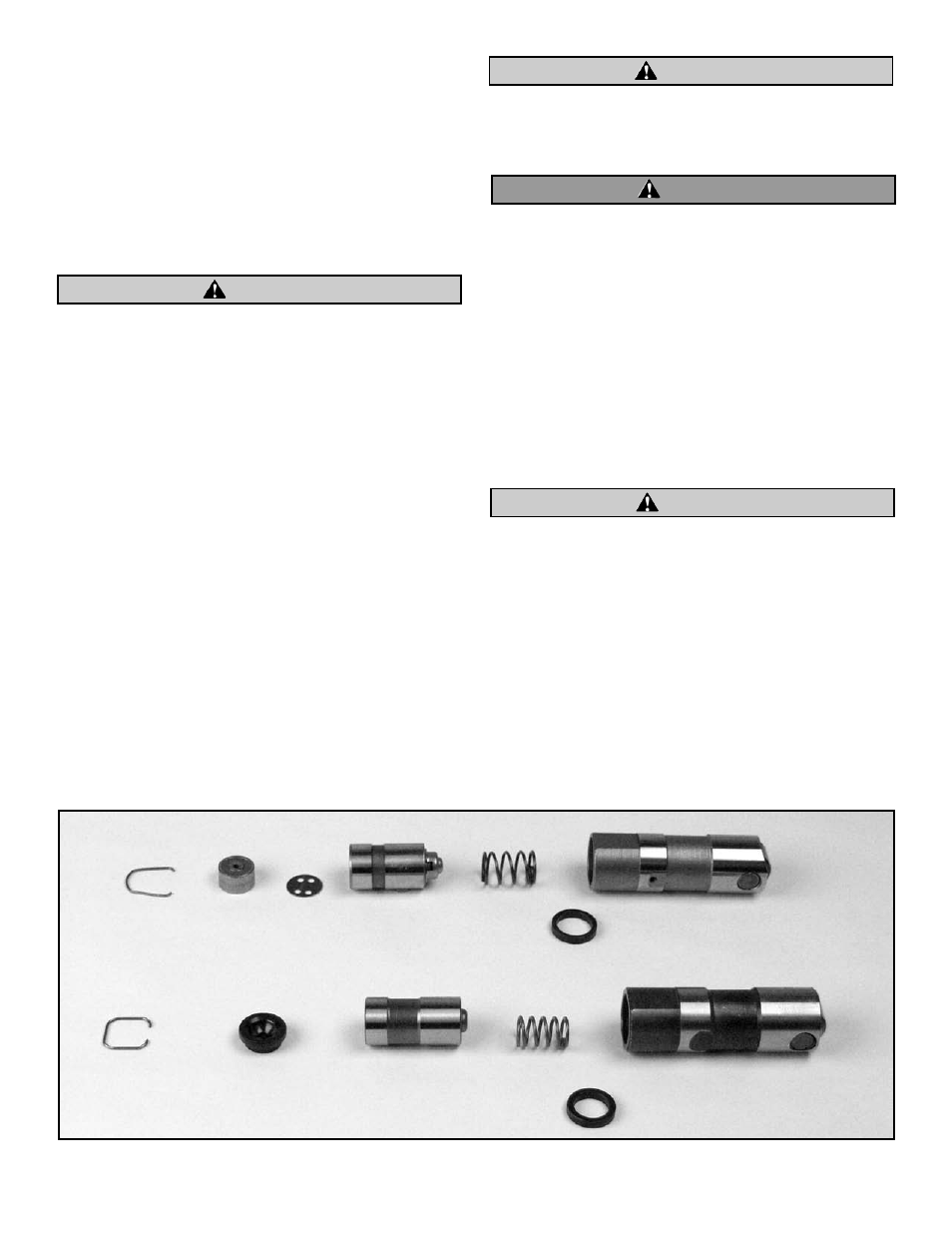

When checking valve to piston clearance pushrods must be

adjusted so the hydraulic piston in tappet is bottomed in the

tappet bore or on the HL

2

T washer if used. This insures that

tappets can not bleed down so valve position will be

accurate for clearance check.

Insufficient clearance between piston and valves may cause

them to contact each other during operation resulting in

damage to piston and valve train components.

5. If insufficient clearance exists, machine piston until

proper clearance is achieved.

6. Disassemble top end and clean all parts for

final assembly.

3.

Final assembly.

NOTE - Cleaning parts prior to and during assembly and keeping

parts clean after final assembly are imperative to minimize

contaminants that may circulate in oil and shorten engine life.

Many parts can be cleaned with soap and water first. Then,

reclean all internal parts and gasket mating surfaces using high

quality solvent that does not leave any harmful residues.

Be sure to read and follow manufacturer’s instruction label

before use. Use drill bits and compressed air to clean all oil

passageways of dirt, filings, etc. whenever possible. All iron or

steel parts should be coated with engine oil immediately after

cleaning to prevent rust. During actual final assembly, recoat all

internal parts with high quality engine oil.

Manufacturing chips, dirt and/or other contaminants

circulating in engine oil may possibly damage engine

components resulting in shorter engine life and possible

engine failure.

●

Some solvents, degreasers and other chemicals are harmful to

skin, eyes and other body parts. Many items are flammable

and present a fire hazard. Read manufacturer’s instruction

label for proper use. Use in well ventilated area and wear

protective clothing when using them to avoid personal

injury.

●

Compressed air and particles dislodged by compressed air

are harmful to eyes and body. Wear protective goggles

when using compressed air and always direct air stream

away from yourself and other people near you.

A. Head gasket surface flatness check. Before top end is

assembled, head gasket to cylinder mating surfaces

should be checked.

Incomplete contact between gasket surfaces of cylinders and

cylinder heads may cause combustion leakage possibly

resulting in damage to cylinders and/or other engine

components.

1. Thoroughly clean head and cylinder gasket

surfaces.

2. Place straight edge across head gasket surface at

different places around diameter to determine

flatness.

3. If unevenness is revealed, machine head gasket

surface just enough to make complete contact.

5

CAUTION

Picture 7

33-5339

18539-99A

33-5338

18539-99B

CAUTION

WARNING

CAUTION