Caution – S&S Cycle Stroker Kits 106 for Harley-Davidson Twin Cam 88 Engines User Manual

Page 2

Introduction

Installation of the S&S

®

3

7

⁄

8

” bore Stroker kit for Harley-Davidson

®

Twin Cam 88

®

engines is relatively straight forward. Assembly

Procedures for the S&S Stroker kit are essentially the same as for

assembly of a stock engine. In addition, a torque plate kit, part

number H-D

®

#39786, is available from Kent-Moore, through

Harley-Davidson, for fitting the S&S 3

7

⁄

8

” bore pistons to stock

Twin Cam 88 cylinders.

All reference to Harley-Davidson

®

part numbers is for

identification purposes only. We in no way are implying that any

of S&S

®

Cycle’s products are original equipment parts or that they

are equivalent to the corresponding Harley-Davidson

®

part

number shown.

NOTE- The 106” kit requires stroker flywheels which are included

with the kit. S&S

®

flywheels for Twin Cam 88

®

engines are

supplied assembled and balanced. The procedure for installing

an S&S flywheel assembly is the same as for stock flywheels.

Installation Steps

1.

Prepare camside crankcase.

2. Check internal engine clearances and assemble crankcases.

3. Final

assembly.

4. Engine break-in procedure.

Installation

1. Prepare Camside Crankcase

A. Refer to appropriate service manual. Remove engine

from frame. Disassemble engine and split crankcases.

B. Temporarily install cams to be used in camside

crankcase. Refer to S&S cam installation instructions.

Turn cams at least one full rotation, and note any

clearance problems between the cam lobes and the

crankcase. Pay particular attention to pinion bearing

boss and tappet guide boss areas.

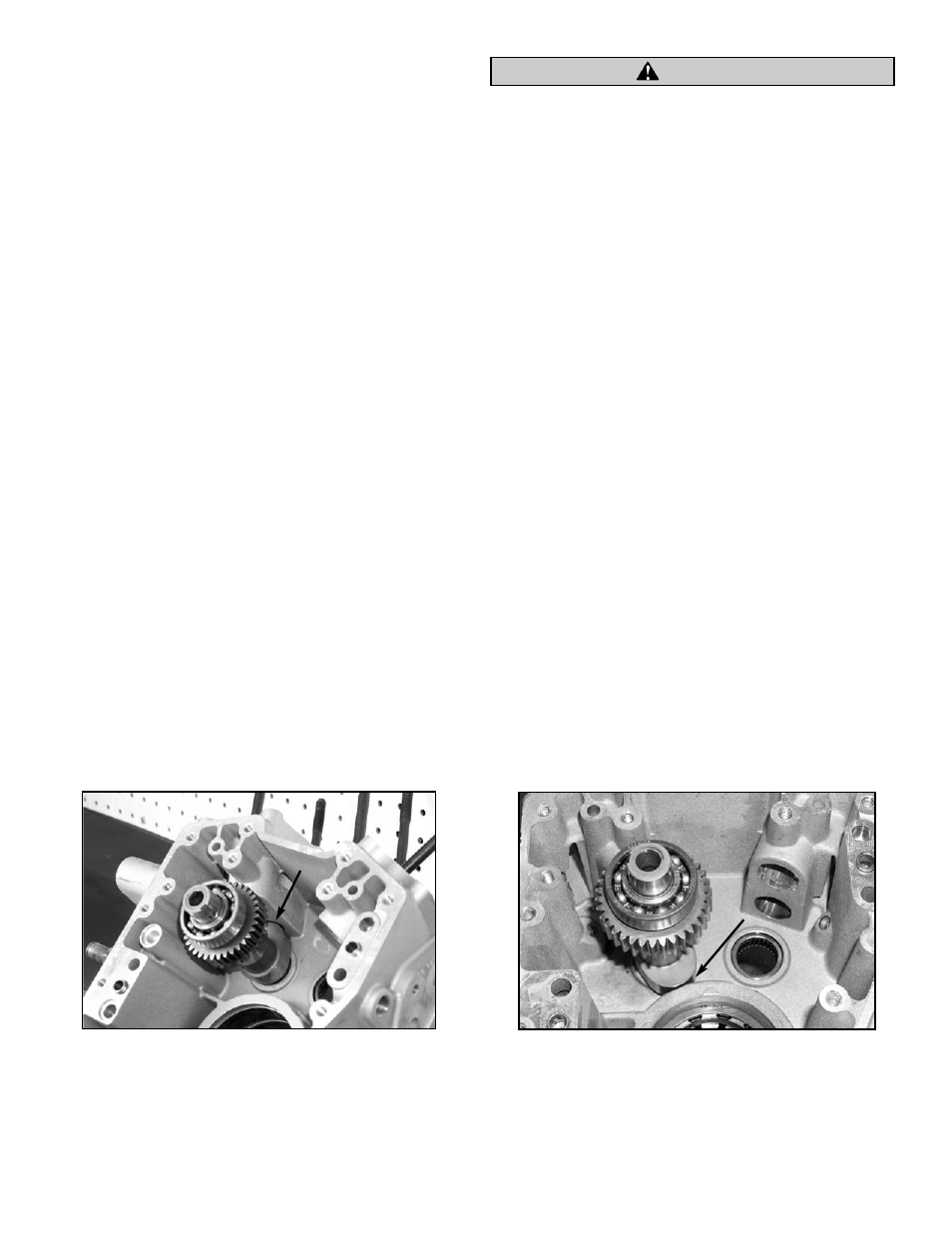

C. Machine material from crankcase to achieve .030”

clearance between cam lobes and crankcase. See

Picture 1 & 2.

Clearance between cam lobes and crankcase must be checked

at pinion bearing boss and tappet guide boss. Machine case

to achieve .030” minimum clearance.

D. Install piston oiler kit, S&S Part #31-2026. Lubricate o-

ring with engine oil. Apply Loctite

®

243 to threads of

machine screws. Install and torque to 25 in-lbs. See

Picture 3.

2. Check internal engine clearances and assemble crankcases.

Many clearance checks can be made at the same time that

some assembly steps are performed. This can save time for

the engine builder.

A.

Cylinder to piston fitment.

1.

The 106” Stroker 3

7

⁄

8

” bore pistons, S&S piston series

92-1210, require a clearance of .002”-.0025” to

cylinder bore. S&S recommends that torque plates

be installed on cylinders when boring and honing

to achieve proper fitment tolerance.

2.

Identify front and rear pistons. The rear piston will

have a notch machined into the piston skirt for

clearance with the front piston. This notch must

face the center of the engine, towards the front of

the motorcycle.

3.

Check piston ring gap. Install piston ring into

finished cylinder and square-up ring to bore using

the piston. The required ring gaps are as follows:

Top two compression rings .016” - .022”

Oil control rings (rails) .015” - .035”

File or grind ring ends as necessary to establish

proper end-gap.

4.

Wash finished cylinder in hot, soapy water to

remove honing abrasive from cylinder bore. Rinse

with clean water and apply a light oil to the bore to

prevent rust.

2

Picture 1

Picture 2

CAUTION

Clearance between cam lobes and crankcase must be checked at pinion bearing boss and tappet guide boss. Grind or machine case

to achieve .030” minimum clearance.