Caution – S&S Cycle Stroker Kits 106 for Harley-Davidson Twin Cam 88 Engines User Manual

Page 3

Cylinders that have not been cleaned with soap and hot

water will release abrasive into the oil as the engine reaches

operating temperature, resulting in accelerated wear of

internal engine components, greatly reducing engine life.

B. Piston to head clearance,

1.

Install flywheel assembly in right crankcase only.

2. Assemble pistons without rings on their proper

connecting rods. Installation of wristpin clips is

not necessary.

NOTE - Rear piston has piston to piston clearance notch machined

in piston skirt, place notch toward center of engine.

3.

Install both cylinders and temporarily secure each

with one nut.

4.

Rotate flywheel to position where pistons are at

TDC. Piston deck should be flush with cylinder head

gasket surface.

NOTE - The stroker engine is designed with .045” piston to head

clearance (squish), which is provided by thickness of head gasket.

Therefore, pistons at TDC should be flush with head gasket

surface of cylinders. If pistons are higher than cylinders at TDC,

then something is wrong and S&S

®

should be notified.

Insufficient clearance between piston domes and cylinder

heads will damage pistons, heads and/or other engine

components.

C.

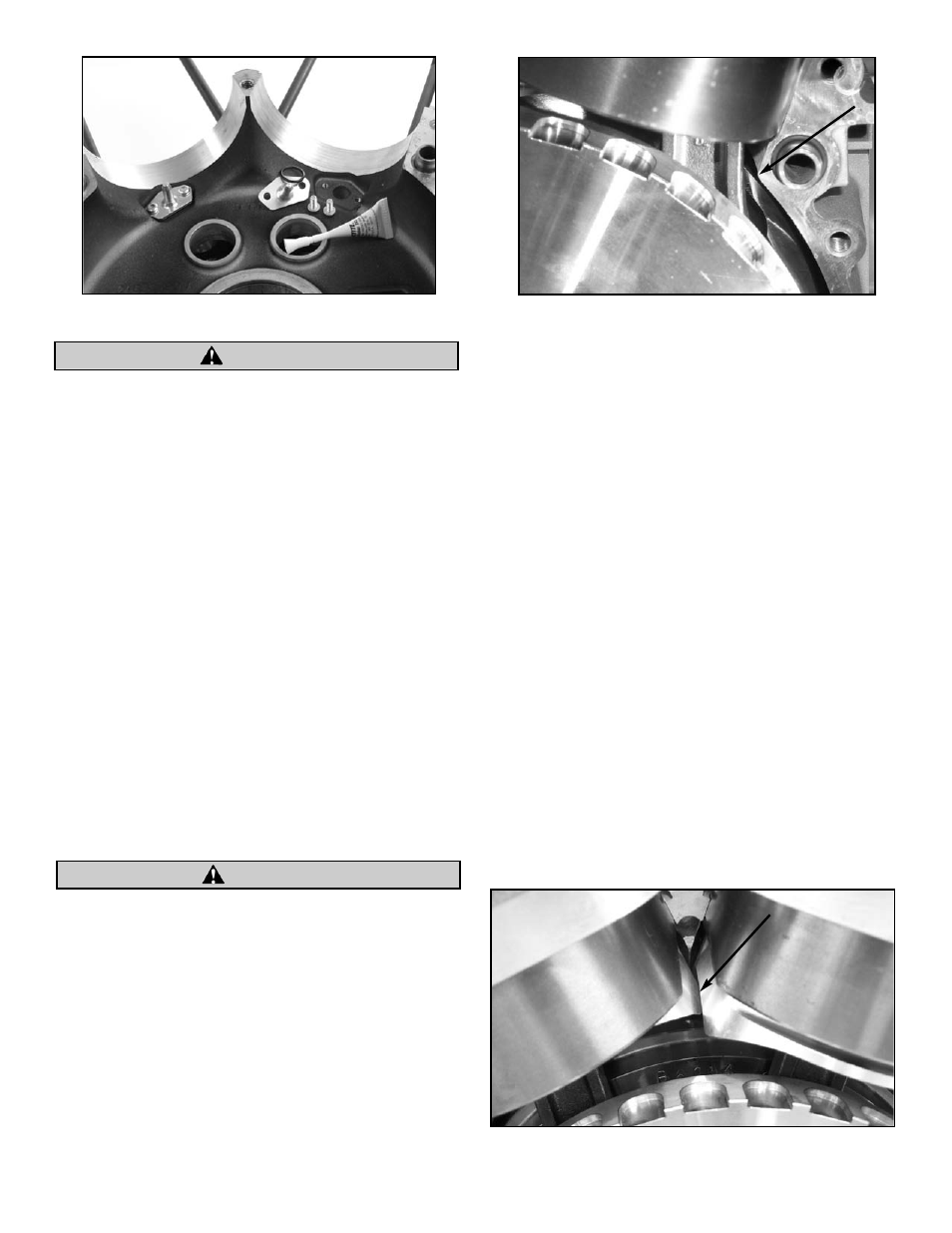

Connecting rod to crankcase clearance.

1.

Rotate flywheel to positions where connecting rods

are closest to crankcase and cylinder spigots in front

and rear. There must be a minimum of .060”

clearance between connecting rods and crankcases

or cylinder spigots. See Picture 4.

2.

Clearance crankcases or cylinder spigots if needed.

Connecting rod to crankcase clearance is usually not

a problem with S&S Stroker kits, but if engines are

built with longer strokes or heavier connecting rods

a potential for contact exists.

NOTE - If clearancing is required. Tape off the pinion and cam

bearings to prevent chips from getting into bearings.

D.

Piston to piston clearance.

1. Rotate flywheel to position where pistons are

closest to each other. See Picture 5. Check clearance

between pistons.

NOTE - A minimum of .060” clearance is required between

pistons at the closest point.

2. If additional clearancing is needed, disassemble

cylinders and pistons and carefully file edge of

piston skirts until clearance is obtained. Clean

all parts.

E.

Piston to piston oiler clearance. This step can be done at

the same time as Step C above.

1. Rotate flywheel to position where rear piston is at

bottom of travel.

2. Check clearance between piston skirt and piston

oiler. See picture 6.

3. Repeat for front piston.

4. If clearance between piston skirts and piston oilers

is less than .060”, file notch in piston skirt to achieve

required clearance.

3

Picture 3

Picture 4

CAUTION

CAUTION

Picture 5