S&S Cycle Stroker Kits 106 for Harley-Davidson Twin Cam 88 Engines User Manual

Page 4

F.

Assemble lower end - final assembly.

1.

Disassemble cylinders and pistons. Remove flywheel

assembly from right crankcase.

2. Clean all lower end parts for final assembly.

NOTE - Cleaning parts prior to and during assembly and keeping

parts clean after final assembly are imperative to minimize

contaminants that may circulate in oil and shorten engine life.

Many parts can be cleaned with soap and water first. Then,

reclean all internal parts and gasket mating surfaces using high

quality solvent that does not leave any harmful residues.

3. Install flywheel assembly. Follow factory procedure.

4. Bolt crankcases together. Use S&S

®

torque specs for

crankcase bolts. Torque case bolts in two stages to

10 ft-lb. and finally 15 ft-lb. in the sequence shown

in Figure 1.

5. Assemble gear case components. Follow S&S

instructions if installing S&S gear drive cams. Follow

factory procedures for all other components.

G. Check valve pocket fit.

1. Install pistons without piston rings on correct

connecting rods. Install cylinders.

2. Turn engine over until piston in front cylinder is at

top dead center. Paint area around valve pockets

on pistons with machinist’s blue.

3. Place valves in cylinder head leaving off springs and

retainers. Place head on cylinder and secure with

one bolt.

4.

Lower valves until they contact piston. Rotate valve,

marking painted area.

5. Remove head and check points of contact. Valve

should fit in valve pocket machined in piston dome.

6. If insufficient clearance exists, remove piston and

machine valve pocket until head of valve fits flush.

7. Repeat procedure for other cylinder head.

H.

Check Valve to piston clearance at TDC.

1. Spread layer of putty into valve pockets in

both pistons.

2. Assemble cylinder heads and bolt on cylinders with

head gaskets in place. Install rocker covers and

pushrods. Adjust pushrods so the hydraulic piston

in tappet is bottomed in the tappet bore or on the

HL

2

T washer if used. This insures that tappets can

not bleed down so valve position will be accurate

for clearance check.

NOTE- The earlier Harley-Davidson

®

Twin Cam 88

®

lifters, H-D

®

part numbers 18538-99 & 99A, require the S&S HL

2

T kit number

33-5339. Later lifters, H-D

®

part number 18538-99B, require the

S&S HL

2

T kit number 33-5338. Both kits are included with the

stroker engine kits, and either kit is installed & adjusted the same

way - remove the retaining clip from the top of the lifter, and

remove the piston assembly and spring from lifter body. Place the

appropriate HL

2

T travel limiter into the bore of the lifter and

replace removed components in the order that they were

removed. See Picture 7.

All reference to Harley-Davidson part numbers is for

identification purposes only. We in no way are implying that any

of S&S

®

Cycle’s products are original equipment parts or that they

are equivalent to the corresponding Harley-Davidson part

number shown.

3.

Turn engine over in normal direction of travel two

complete revolutions.

4. Disassemble engine and check thickness of putty in

valve pockets.

4

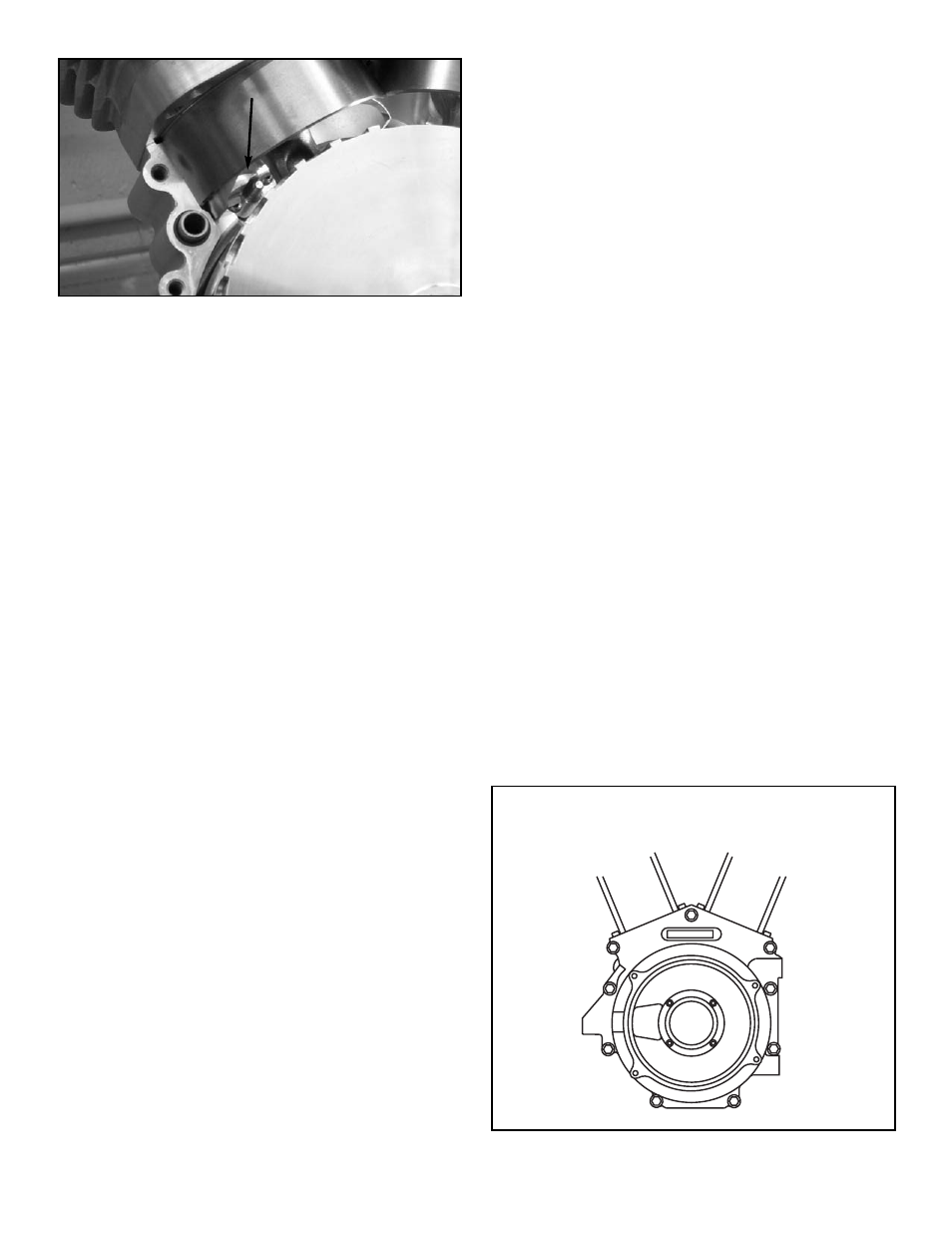

Picture 6

Torque In Sequence

Shown In Two Stages.

Stage 1 - 10 ft-lb.

Stage 2 - 15 ft-lb.

4

6

2

8

5

1

7

3

9

Figure 1