S&S Cycle IST Ignition System for 1984-1999 Big Twin and Custom Applications User Manual

Page 7

g. Secure the sensor cup in place using the provided brass screw. Use Loctite® 243 (blue) on the first three threads and tighten securely (15-

20 in/ lbs.).

NOTE: The non-magnetic 10-32 brass panhead screw provided in the installation kit must be used to attach the rotor to the end of the camshaft. Screws

made of metal other than brass (including stainless steel) may affect the function of the VR sensor.

h. Rotate back tire to position TDC (Top Dead Center) mark on Flywheel in center of timing hole. For timing mark identification, see Figure

1, below.

NOTE: Valve spring pressure will tend to rotate the flywheels out of position. One method to hold the flywheels in position is to have an assistant apply the

rear brake to secure the flywheels during the ignition plate alignment procedure.

The engine must not be allowed to rotate while the alignment pins are in place. If the engine rotates while the alignment pins are

installed, permanent damage to the components will occur.

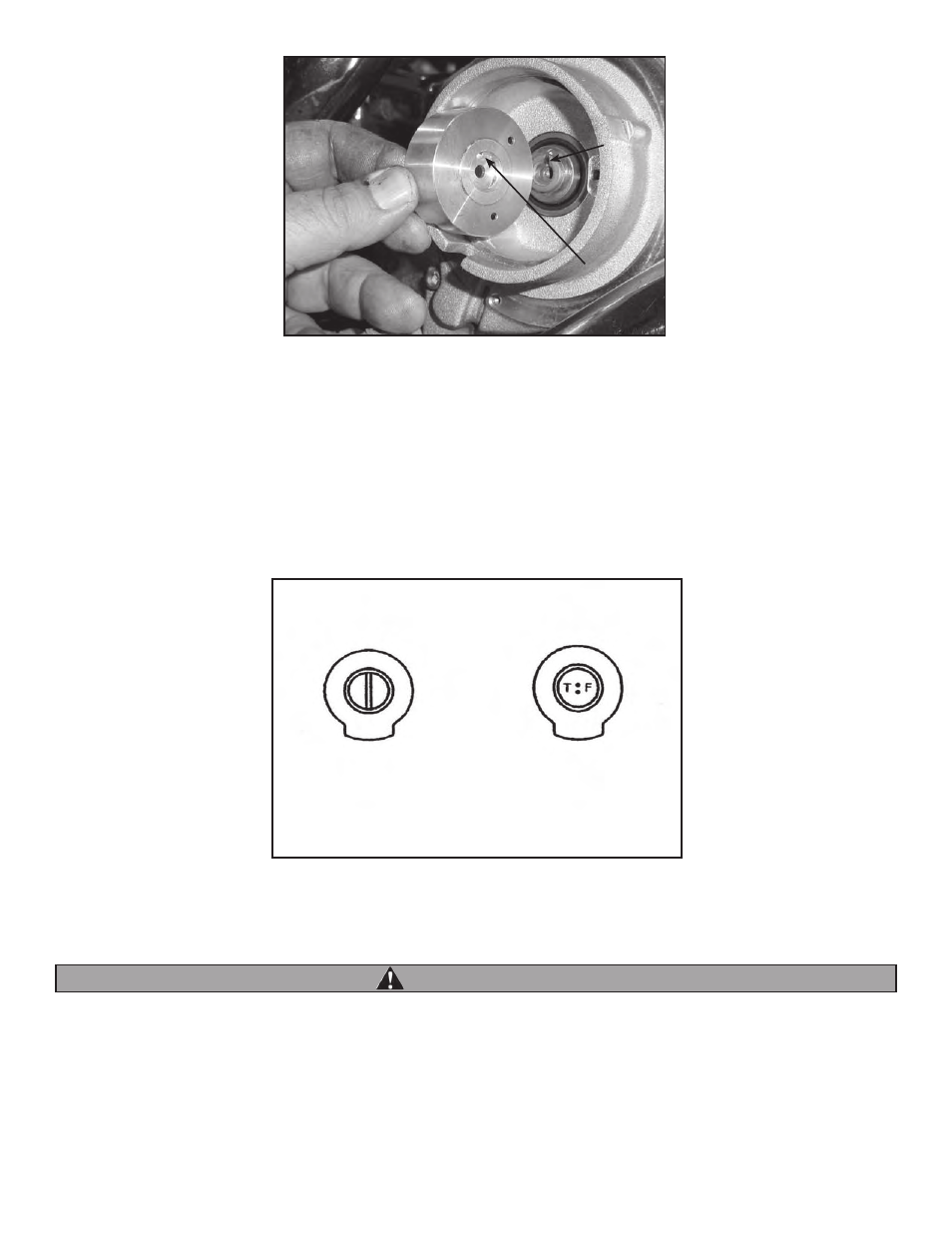

i. After locating the TDC mark in the timing hole, verify that the engine is at TDC of the compression stroke. To do this, check the position

of the holes in the end of the installed sensor cup against the holes in Picture 10, next page.

j. Place the two steel alignment dowels into the holes in the installed sensor cup.

k. Route sensor plate wires through passages in nosecone. Connectors are installed later.

7

1981 & later OEM

Top Dead Center Timing Marks for big twin and

Harley-Davidson® Sportster® models.

All S&S

Figure 1

Picture 9

Slot

Pin

WARNING