S&S Cycle IST Ignition System for 1984-1999 Big Twin and Custom Applications User Manual

Page 12

• Crimp connections are preferred over soldered connections. Soldering causes stress concentrations at the wire to solder joint. Soldered

connections are prone to break in high vibration environments.

• In most cases, the switched ignition power connection is made in the wire leading from the ignition switch to the coil.

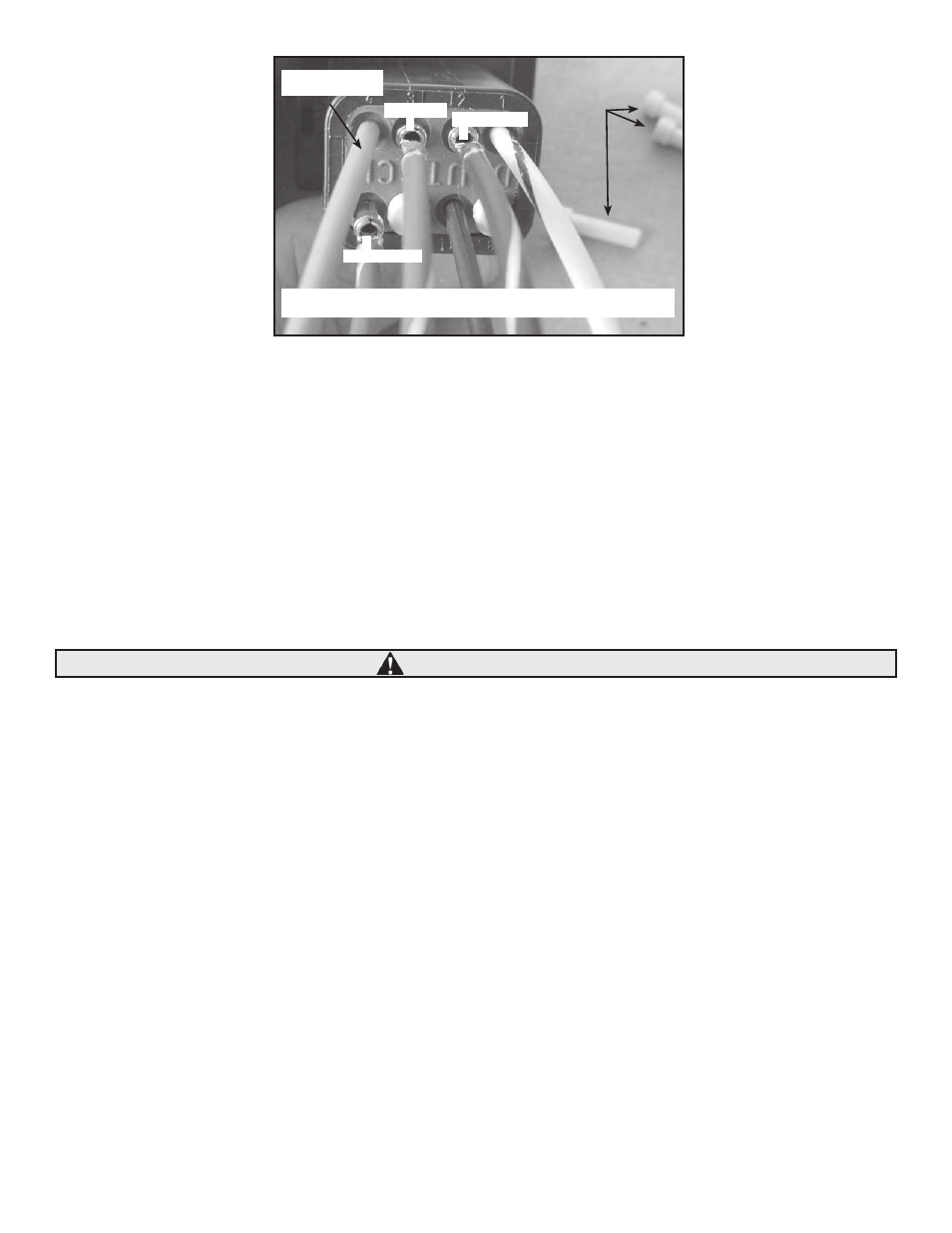

• If not using a tach, the tach signal wire may be removed from the connector. See Picture 18, above.

F. Initial Starting and Operation Procedure:

Because the S&S® Intelligent Spark Technology Ignition System is designed to “learn” the specific engine/motorcycle configuration it is being

used for, the following initial starting and operating procedures must be followed after installing the system for the first time. These procedures

need to be followed only once. After that, the motorcycle can be started and ridden as usual.

1. Initial Starting Procedure

Damage to coil may result if Steps (a) thru (c) below are not followed.

a. After installation is complete, disconnect the coil connector on the S&S main harness. See Picture 13, page 9, item “f”.

b. Crank engine with spark plugs removed for approximately 5 seconds.

c. Leave the ignition switch on for approximately 5 seconds to allow the ignition system to “learn” the specific motorcycle application for

which it is installed.

d. After performing Steps 1-3, reinstall spark plugs and reconnect coil.

2. Initial Operating Procedure

Initially, the S&S Intelligent Spark Technology Ignition System operates using a standard ignition-timing map that may not be optimum but

is considered “safe” for most engine configurations. After 3 to 5 hours of operation, with the engine warmed up, the IST Ignition System will

have adjusted the map to create one that is optimized for the particular engine configuration. See Step 2-a. The IST system will continually

adapt to subsequent changes in riding style, fuel quality, weather conditions and elevation to further optimize the ignition map. For this

reason, data recorded using a chassis dynamometer should be measured after the system has had sufficient time to learn the specific engine

parameters.

Ride your motorcycle as you normally would during this initial “learning” period. The IST system will learn and adapt the ignition map to

various conditions as they are encountered – so the more riding you do, the more the system will fine tune itself. Below are some suggested

practices to help the system quickly create the initial optimized timing map:

a. Allow engine to remain at normal operating temperature for at least an hour.

b. Ride up hills and/or inclines.

c. Ride at highway speeds for at least 20 minutes. When road conditions are safe, briefly (1-2 seconds at a time) open the throttle all the

way.

d. Ride through intersections/stretches of road where second and third gear roll-ons are required.

e. Ride at highway speeds for at least 20 minutes. When road conditions are safe, briefly (1-2 seconds at a time) open the throttle all the way.

12

Picture 18

Discard sealing

pins from rear

of connector

green/white

red/white

black/white

2

3

5

CAUTION

Pink tach wire

in #4 is optional

Insert three wires from cam harness into rear of power harness.

Insert wires fully, then replace locking wedge into front of connector.