S&S Cycle Balancing Kit User Manual

Page 2

Introduction

The S&S® balancing kit is designed to allow the engine builder to

statically balance each flywheel separately in Harley-Davidson®

engines. The static method of balancing uses gravity to cause the

heaviest part of the flywheel to rotate downward when placed on the

balance stand. Weight is then removed from the heavy side by drilling

holes. When the flywheel no longer rotates, it is in balance.

The object of balancing the flywheels is to minimize engine vibration

which improves performance and riding comfort and avoids damage

to engine and chassis components. Usually the rider is quick to blame

engine flywheel imbalance as the cause of the problem. We have found

that the problem often lies elsewhere.

Improper engine installation in the frame, poor engine and transmission

sprocket alignments, flywheels not properly trued, tires out of balance,

faulty frame design, poorly balanced stator and/or clutch hub, worn

primary drive chain, and rigidly mounted handlebars are a few areas

that can cause vibrations often blamed on flywheel balance. Improper

installation of the engine in the frame and other chassis components

that are bolted on the frame sometimes form a resonant effect resulting

in vibration at certain rpms. This explains why an engine which runs

smoothly in one frame may vibrate when placed in another frame with

different forks. Only after investigating all of these other areas should

the engine be checked.

The 45˚ design of the Harley-Davidson® engine makes it difficult to

obtain perfect flywheel balance that will make the motorcycle vibration

free at all rpms. The goal is to make the motorcycle as vibration free

as possible and perform the best in the rpm range where the most

riding is done. If the engine is used exclusively for drag racing, it may

be desirable to balance for higher rpm ranges - say 3000 rpm upward.

Most street riders run their engines in the 2000 rpm to 5000 rpm range

most of the time.

The balance factor we use and recommend is 60%. We arrived at this

percentage after much experimentation, and found it to give the best

results over the rpm range that riders most commonly use. Factors

other than 60% will change the direction and amplitude of vibration.

For example, if the balance factor is 50% or less, the engine will tend to

vibrate vertically. As the percentage is increased, this vertical motion

changes to horizontal motion. Horizontal motion from our experiments

is more acceptable with less noticeable vibration transmitted to the

rider. Therefore, 60% is the percentage S&S uses as a compromise for

best all around performance and riding comfort.

Balance formula

The components which must be compensated for when balancing

Harley-Davidson® flywheels are placed in two categories.

Reciprocating parts - Reciprocating parts are those parts which

travel in a reciprocating (up and down) motion. These are the pistons,

piston rings, wristpins, wristpin clips and the wristpin ends of the

connecting rods. The total weight of the reciprocating parts equals the

reciprocating weight.

Rotating parts - Rotating parts are those which move in a circular

motion. The crankpin, crankpin nuts, bearings, bearing cages, nut locks

and screws, and crankpin end of both connecting rods are rotating

parts whose weights when added together equal the rotating weight.

The balance formula used to calculate the weight of the bobweight

that must be bolted into each flywheel is:

NOTE: S&S uses 60% of the reciprocating weight. When we speak of

the “balance factor,” we usually refer to the percentage of the total

reciprocating weight used in balance calculations.

Balancing procedure

Perform following steps to balance flywheels:

1. Weigh Parts

All reciprocating and rotating parts to be used must be weighed

and recorded to calculate weight of bobweight. For greatest

accuracy S&S recommends using gram scale. Weigh and record

weight of:

A. Front piston.

B. Front piston wristpin.

C. Front piston wristpin clips/buttons.

D. Front piston rings.

E. Repeat steps A through D for rear piston.

NOTE: Weighing parts separately allows for direct comparisons of parts in

event parts are replaced at some later time.

F. Crankpin.

G. Crankpin nuts.

H. Crankpin key.

I. Bearing cages.

J. Bearings.

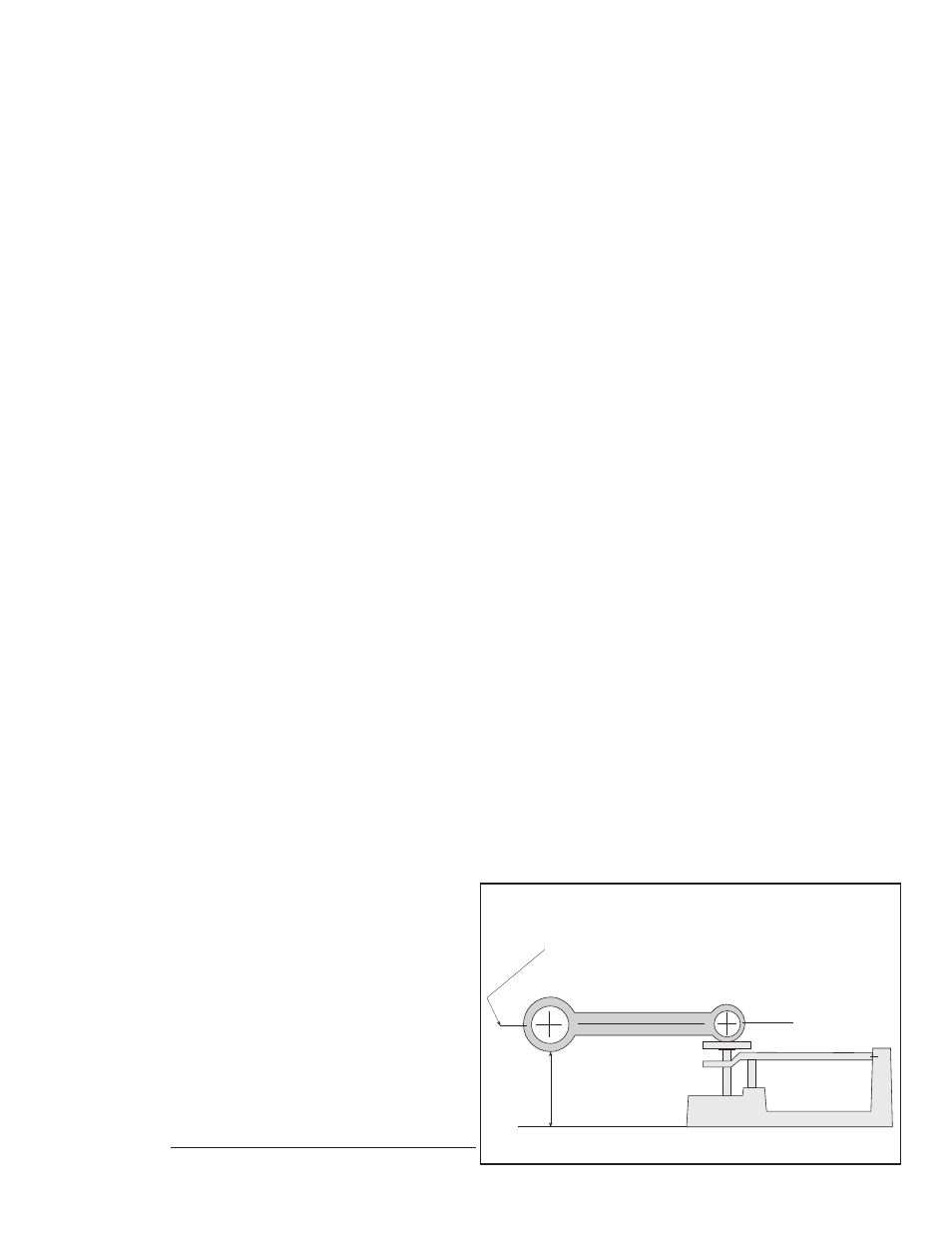

K. Small end of front rod. See Figure 1 for correct positioning to

weigh connecting rod.

NOTE: To get correct weight of each end of rod, centerline of rod must

be level horizontally when pointer of scale is at zero position. Eyeball rod

position and adjust rod support stand accordingly. A card with horizontal

lines placed behind scale makes leveling of rods easier. Rest edge of rod

that exhibits smoother contours on platform and rod support stand.

Grinding marks and/or forging seam lines may cause unwarranted friction

which may distort actual balance weight of rod.

L. Big end of front rod.

M. Complete front rod.

2

Weight of

bobweight

per flywheel

(60% x reciprocating weight) + (100% x rotating weight)

2

=

Centerline of rod must be level horizontally when pointer of

scale is at zero. Eyeball rod position and adjust rod support

stand accordingly. Rest edge of rod the exhibits smoother

contours on platform and rod support stand. Grinding marks

and/or forging seam lines may cause unwarraned friction

which may cause errors in rod weight readings.

Figure 1