S&S Cycle Replacement Cylinder Heads for 1984-1999 Harley-Davidson Evolution Engines and 1986-2003 Sportster Motorcycles User Manual

Page 7

M. Bolt heads on cylinders. Clean threads of head bolts and

cylinder studs. Place one or two drops of oil on threads

of each head bolt just prior to final assembly to reduce

friction and insure accurate torque readings. Tighten

bolts in stages using crossing pattern. If using S&S

®

or

stock crankcases, follow the the torque and sequence

chart. See Figure 4. If using other aftermarket

crankcases, contact the manufacturer for recommended

head bolt torque specifications.

NOTE: Light coating of oil on head bolt threads minimizes friction

so torque values are not distorted. It cannot be emphasized

enough how important it is to do these steps carefully.

Maintaining a good head gasket seal depends on it.

Improper torquing sequence and head bolt torque values may

cause head gasket failure. Excessive torque values may cause

studs to pull out of crankcase.

6.

Finish Assemble Top End, Install Carburetor and Replace

Gas Tanks

Follow Harley-Davidson

®

factory procedures outlined in

Harley-Davidson

®

service manual to assemble rocker cover

components and other parts that were removed for top end

service.

A.

Install rocker arm bases per Harley-Davidson

®

specs.

B.

Assemble rocker arms, pushrods and pushrod tube

assemblies and adjust pushrods.

C.

Install rocker covers using gaskets provided.

D.

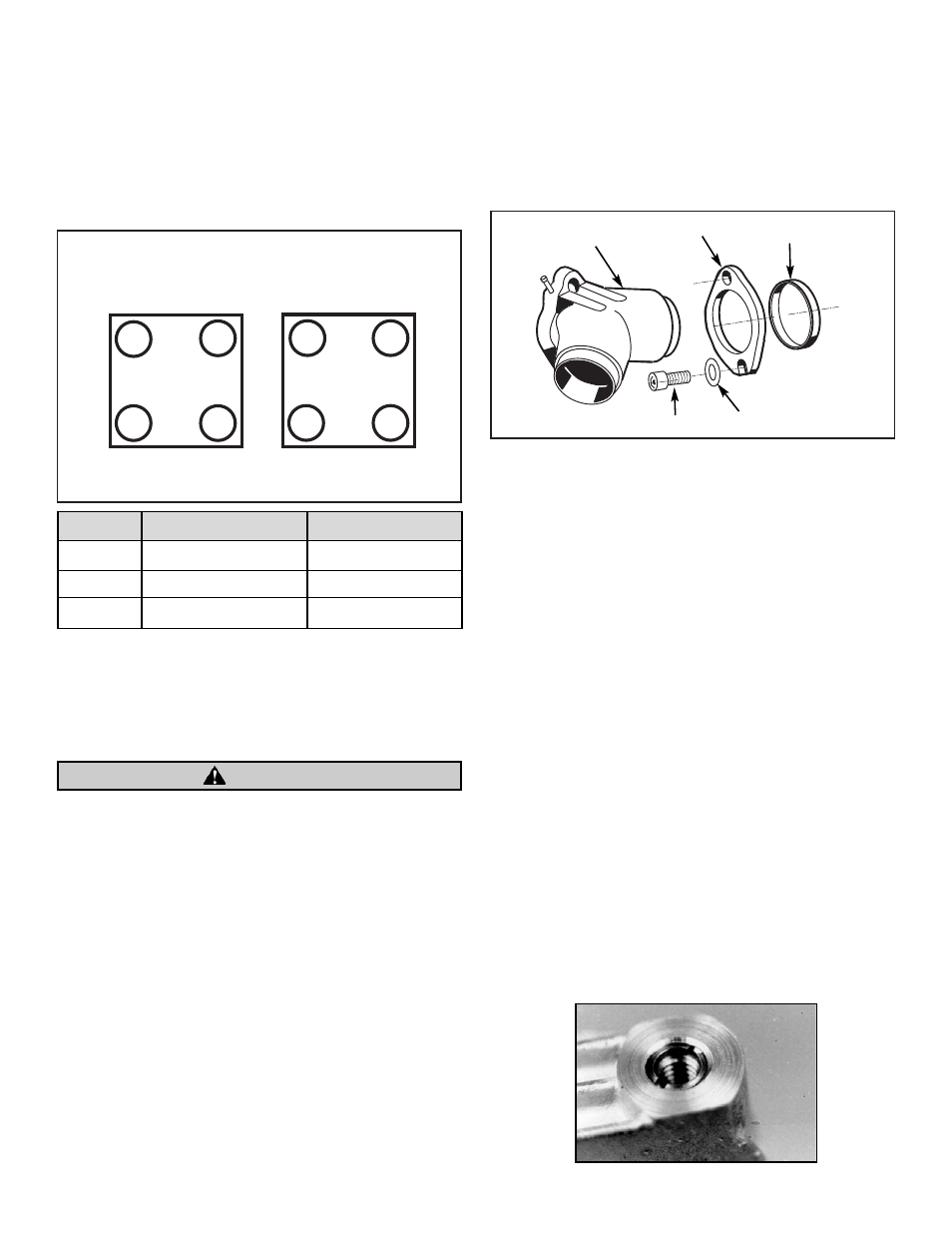

Install intake manifold, mounting flanges and O-ring

seals provided. Be sure O-rings and flanges are

assembled in correct sequence. See Figure 5.

Use

flange marked "F" on front head and flange marked

"R" on rear. Slotted end of mounting flange goes

toward lower manifold mounting hole. Flat washer

provided is used on slotted end of flange. Do not

tighten mounting flange screws.

NOTE: Special S&S manifold must be used with S&S heads

because intake port diameters of S&S heads are larger than

stock. Special S&S manifold requires O-ring seals which also

have larger than stock diameter to fit O.D. of manifold runners.

These O-rings, S&S part 16-0235, are included and cannot be

used in stock applications.

E.

Bolt carburetor and air cleaner assembly in place using

carburetor instructions supplied from manufacturer.

NOTE: S&S cylinder heads are machined for use on all big twin

engines. Heads are drilled and tapped to accept

1

⁄

2

"-13 air cleaner

mounting bolts used on 1992 big twin heads or

1

⁄

2

"-13 threaded

cylinder head vent fittings used on 1991 and later Sportster

®

models and 1993-up big twins. For installation on 1984 to '91 big

twins and 1986 to '90 Sportster

®

models, screw thread reducing

inserts, part 90-4026, in carburetor backplate mounting holes in

cylinder heads. Surface of insert should be just slightly below

machined surface of head so backplate rests against head and

not insert. See Picture 2. Insert (threadsert) will reduce hole to

5

⁄

16

"-18 threads to accept stock 1984 to '91 air cleaner mounting

bolts. Threadserts may be supplied with or without a thread

locking compound already applied to threads. Loctite or

equivalent thread locking compound should be applied sparingly

to threads of those not pre-coated during installation.

Threadserts with preapplied thread locking compound should be

installed in desired position and left in place. IMPORTANT -

Screwing threadsert in hole activates compound and locks it in

position making it difficult to change after compound has set up.

1

2

4

3

Rear Head

2

1

3

4

Front Head

Top View

Driveside

Camside

Figure 4

S&S

®

Crankcases

Stock Crankcases

Stage 1

8 ft-lbs.

7-9 ft-lb

Stage 2

18 ft-lbs.

12-14 ft-lbs.

Stage 3

Turn Additional 90°

Turn additional 90°

CAUTION

Figure 5

Flange

O-ring

Manifold

Screw

Washer

Picture 2

7