Caution, Caution warning caution – S&S Cycle Replacement Cylinder Heads for 1984-1999 Harley-Davidson Evolution Engines and 1986-2003 Sportster Motorcycles User Manual

Page 5

NOTE: Do not bend rod by using tool in wristpin hole as this method

may distort wristpin bushing. We also feel that using a piston in lieu

of a checking pin may prove inaccurate due to variations in lengths

of piston skirts from one side of piston to the other.

E.

Repeat checking and bending procedure for the

other rod.

3.

Piston and Cylinder Fitting

NOTES:

●

For maximum piston and ring life, fit pistons using

appropriate close fit dimensions. Close fit requires strict

adherence to new engine break-in procedures.

●

For immediate drag strip use, fit pistons using appropriate

loose fit dimensions. Attempt to break in rings and pistons

with 50 easy miles if possible. Piston and ring life will be

reduced when using loose fit dimensions.

Failure to follow instructions and perform required

clearancing, installation and/or break-in procedures correctly

may result in damage to pistons and/or other engine

components. S&S

®

voids its guarantee if pistons are not

installed and/or broken in properly.

A.

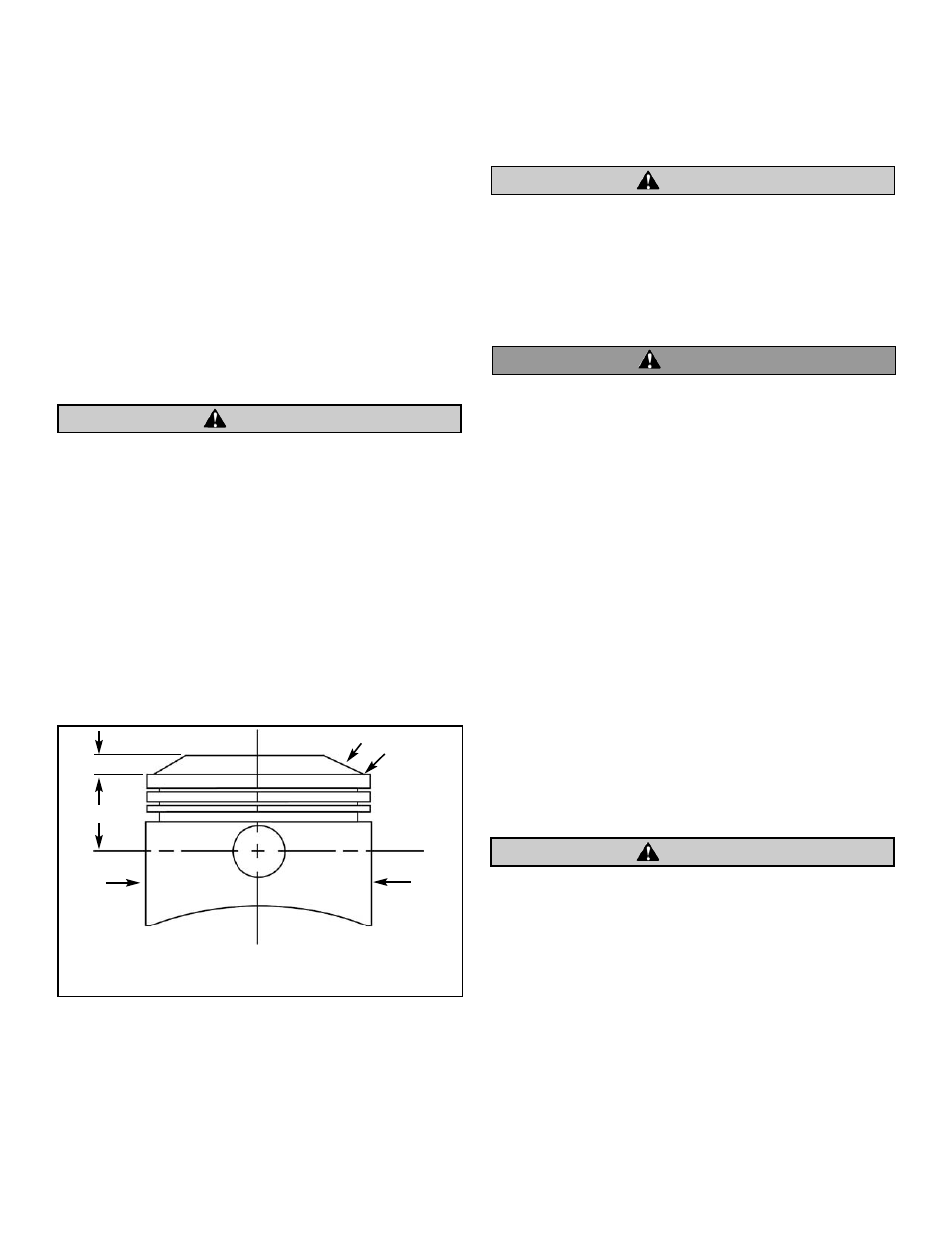

Measure piston across thrust face 90° to wristpin hole.

Make a series of measurements starting directly below

oil ring groove and ending at extreme bottom of skirt.

Use widest measurement to represent size of piston.

See Figure 3.

NOTE: All 3

1

⁄

2

" and 3

5

⁄

8

" bore pistons for S&S Super Stock

®

cylinder

heads have barrel shaped skirts. As a result, largest diameter is

located

1

⁄

4

" to

1

⁄

2

" above extreme bottom of skirt. See Figure 3.

B.

Determine size of cylinder. Refer to S&S piston fitting

instructions 51-1028 for the clearance specifications.

C.

Bore and hone cylinder to size required for piston plus

proper desired running clearance. Use torque plates

torqued to 50 ft. lb. to simulate stresses in an

assembled engine.

NOTE: S&S recommends using a 220 grit stone during final

honing process. Using finer than 220 grit stones will result in

smoother cylinder wall finishes which do not provide sufficient

abrasion between cylinder wall, piston and rings nor sufficient oil

retention for proper lubrication required for break-in.

Insufficient cylinder wall lubrication during break-in process

may result in piston scuffing and damage to pistons, rings

and/or cylinders.

D.

Thoroughly clean cylinders, pistons and all parts

required to reassemble engine. Use high grade lacquer

thinner on gasket surfaces.

●

Some solvents, degreasers and other chemicals are

harmful to skin, eyes and other body parts. Many items

are flammable and present a fire hazard. Read

manufacturer's instruction label for proper use. Use in

well ventilated area and wear protective clothing when

using them to avoid personal injury.

●

Compressed air and particles dislodged by compressed air

are harmful to eyes and body. Wear protective goggles

when using compressed air and always direct air stream

away from body parts such as hands and eyes. Never

direct compressed air toward other people.

4.

Rebalance Flywheels (883 & 1100 Harley-Davidson

®

Sportster

®

models only)

This step applies to all Super Stock cylinder head installations

on Sportster

®

883 and 1100 engines.

NOTE: S&S Super Stock 3

1

⁄

2

" and 3

5

⁄

8

" bore matching pistons

are designed to replace stock 1200cc and 1340cc pistons and

S&S 92-2420 and 92-1900 series pistons without requiring

flywheel rebalancing. This also means that engines presently

equipped with 3

1

⁄

2

" bore can be converted to 3

5

⁄

8

" bore

without rebalancing. Rebalancing is required only when

converting 883cc and 1100cc stock bore Sportster

®

engines to

3

1

⁄

2

" or 3

5

⁄

8

" bore.

When converting 883cc and 1100cc stock bore Sportster

®

engines to 3

1

⁄

2

" or 3

5

⁄

8

" bore, failure to rebalance engine will

cause engine vibrations possibly resulting in damage to

engine components.

A.

Follow Harley-Davidson

®

factory procedures outlined in

Harley-Davidson

®

service manual for removing and

disassembling engine.

B.

Rebalance flywheels.

NOTE:

If engine is expected to be used under extreme

conditions, it is recommended that the connecting rods in

engines prior to 1989 be changed to Harley-Davidson

®

part

#24275-86A or S&S 34-7800 as either of these assemblies is

stronger than early stock Harley-Davidson

®

connecting rods.

CAUTION

Figure 3

CAUTION

WARNING

CAUTION

Dome

Deck

C

C

B

A

A. Piston dome height.

B. Piston deck height.

C. Measure piston diameter on thrust face 90° from wristpin.

Largest diamete will be

1

⁄

4

" to

1

⁄

2

" from bottom piston skirt.

5