Caution – S&S Cycle Replacement Cylinder Heads for 1984-1999 Harley-Davidson Evolution Engines and 1986-2003 Sportster Motorcycles User Manual

Page 4

2.

Check Piston Alignment in Cylinder Bore

The purpose of this procedure is to check for and correct

possible piston misalignment in the cylinder bore. During

normal manufacturing, engine components such as

crankcases, cylinders, and connecting rods can be machined

to dimensions within factory specifications but on the

extreme ends of the tolerance range. Sometimes these

components when combined together form an assembly

that is borderline or actually "out of print". The worst result

is that the pistons can run cocked in the cylinder bores

causing the connecting rods to thrust to the sides exerting

unnecessary stress on the pistons, rings, rod bearings and

other related parts. This procedure is not the same as blue

printing, but it provides almost the same result. We feel that

not enough emphasis is given to checking the piston

alignment in the cylinder bore.

NOTE: All engines should be checked upon disassembly. This

applies to any engine receiving new pistons which includes those

being completely overhauled.

Pistons which do not run true in cylinder bores may cause

excessive connecting rod side thrusting. This may lead to

premature ring, piston, connecting rod and rod bearing wear

and eventual failure of these parts.

Visual Procedure

A.

Reinstall cylinders on old pistons without rings. Hold

cylinders securely in place.

B.

Move piston tight toward camside of engine.

C.

Turn engine over in normal direction of travel 2 or 3

revolutions and observe piston during process.

D.

Move piston toward driveside of engine and repeat

Step C. If misalignment exists, piston will appear closer

to cylinder wall at one point around circumference.

Condition can be corrected by bending rod in opposite

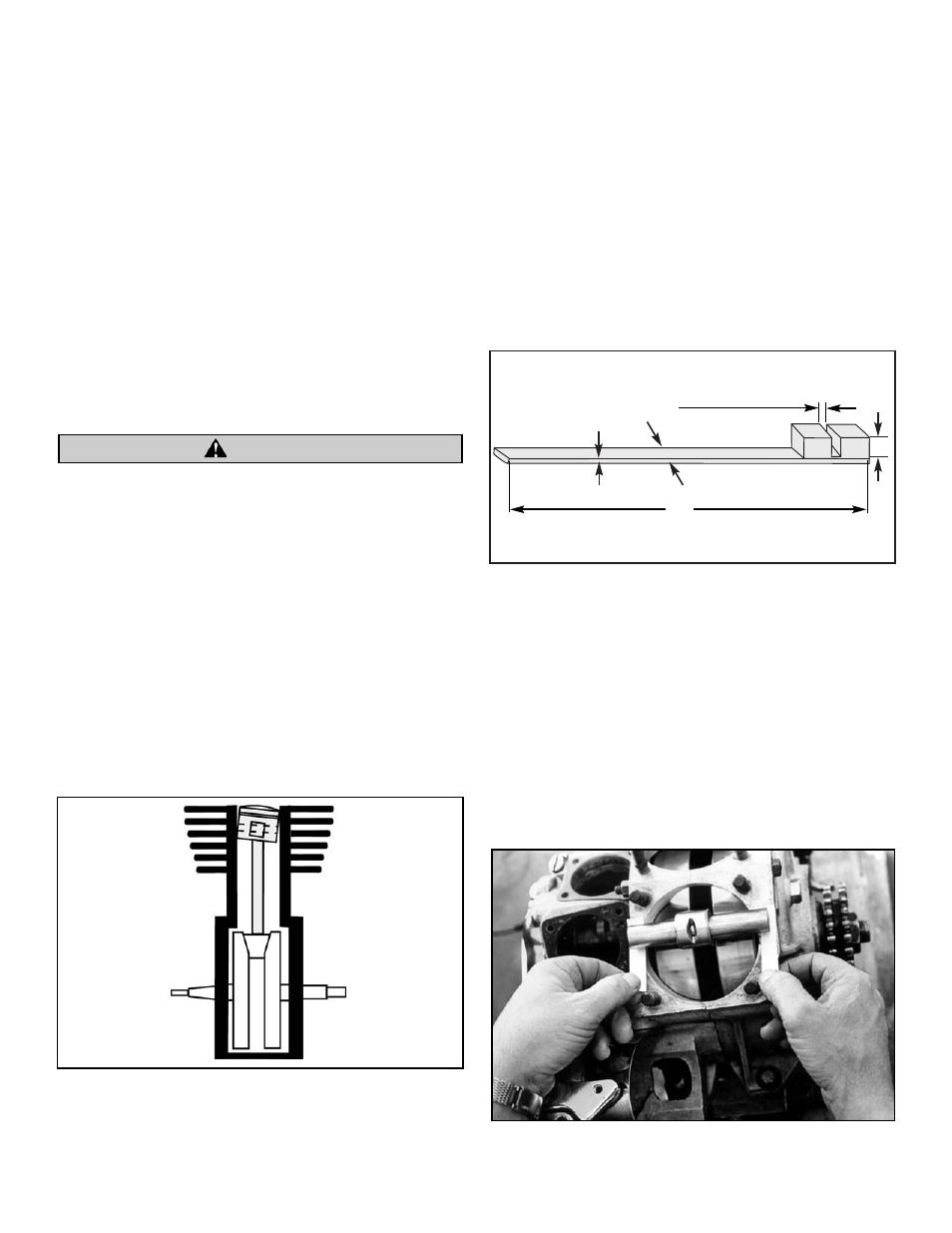

direction. Figure 1 shows an exaggerated side view.

E.

Repeat Steps B to D for other cylinder.

F.

Remove pistons and cylinders. Observe pistons for wear

spots on sides above top compression ring. If either side

near wristpin is worn clean while side opposite is

carboned up, then piston was not running straight and

true in cylinder bore. Piston will also generally show

diagonal wear pattern on thrust faces of skirts and

possibly signs of connecting rod to wristpin boss contact

inside piston.

Checking Pin Procedure

NOTE: S&S

®

rod checking pin, part 53-0002, is designed to help

perform this procedure. It may also be necessary to fabricate a

rod bending tool as illustrated in Figure 2.

A.

Insert checking pin into wristpin hole.

B.

Place strips of paper between checking pin and

crankcase cylinder gasket surface and apply slight

downward pressure to wristpin end of rod by rotating

flywheels.

C.

Pull papers out slowly. Drag on papers should be equal.

D.

Rotate flywheels in opposite direction until checking pin

contacts cylinder gasket surface again. Repeat

procedure to rod again. If drag on papers is equal, no

bending is required. If one paper is loose, use rod

bending tool to tweak rod in direction of loose paper

and recheck. See Picture 1.

4

Figure 1

Figure 2

1

1

⁄

4

"

1

1

⁄

4

"

22"

1

⁄

4

"

.510 to .520 wide slot

Picture 1

CAUTION