Caution – S&S Cycle Gear Drive Cams for Harley-Davidson Twin Cam 88 Engines User Manual

Page 7

7

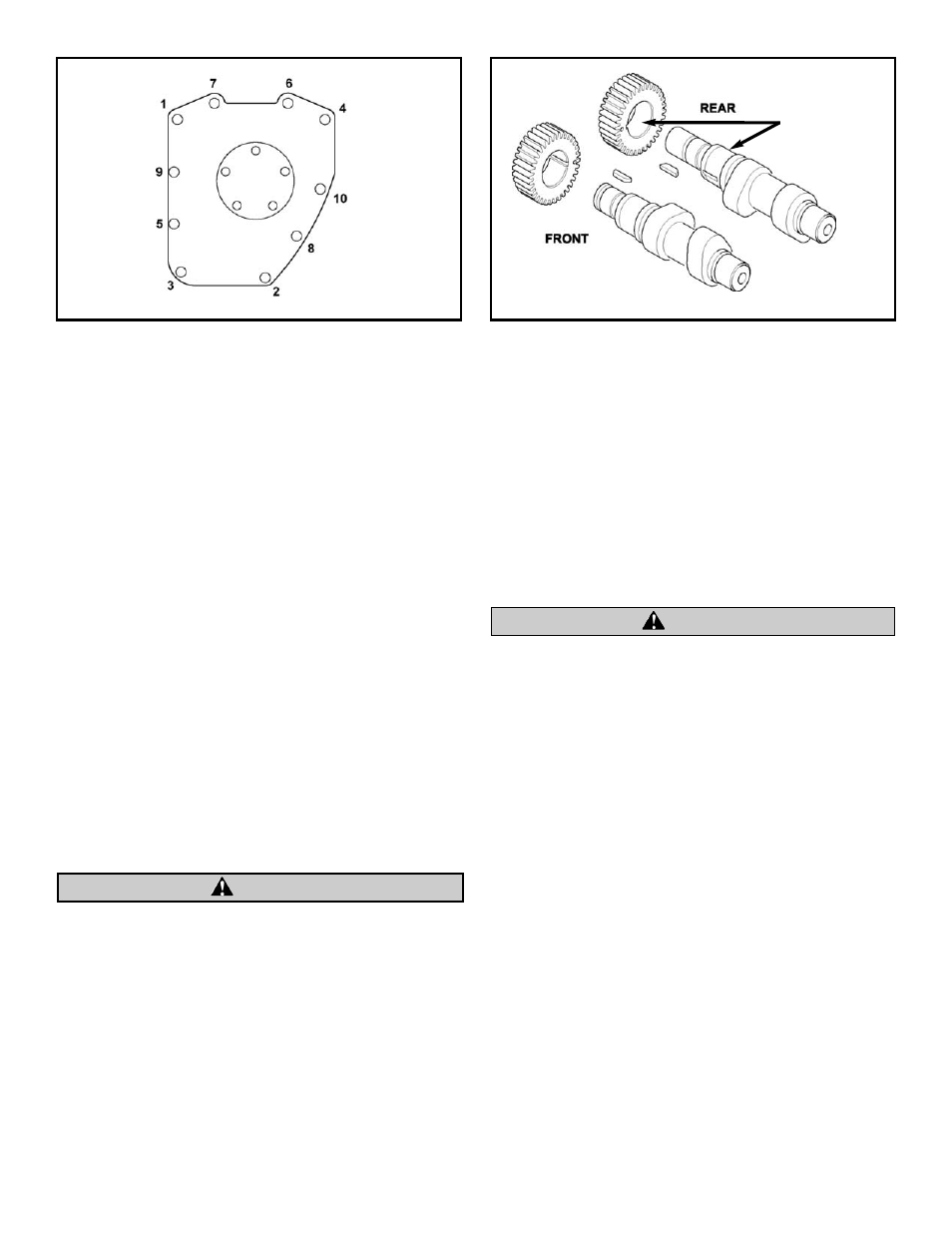

Figure 6

Figure 7

6oq

Green Loctite

®

R.

Loosen locknuts on adjustable pushrods and turn

adjusters to make all rods as short as possible.

S.

Longer S&S

®

pushrods are for exhaust valves, and

shorter ones are for intake. Pass one long and one short

pushrod through assembled pushrod covers. Place

pushrod and cover assemblies through lifter cover. Inner

tappet hole is for intake pushrod, and outer tappet hole

is for exhaust pushrod. While holding a new gasket

under lifter cover, install push rod, pushrod cover, lifter

cover, and gasket as an assembly on crankcase. Tighten

lifter cover screws to 95 in-lbs. torque.

NOTE: Pushrod adjustment. If using unmodified original

tappets perform steps 3-A thru 3-D to adjust pushrods. (See

below.) If S&S HL

2

T kit has been installed in tappets, proceed to

steps 4-A thru 4-F. (See next page.)

3. Pushrod Adjustment Procedure

For Unmodified Stock Tappets

A.

Turn adjuster screw to lengthen exhaust pushrod until

pushrod has no vertical movement but still rotates with

light finger pressure. Extend pushrod by rotating

adjuster screw an additional 20 flats (3

1

⁄

3

revolutions) and

secure adjuster screw with locknut.

B.

Repeat step 2-S for intake pushrod.

C.

Front lifters should bleed down in 5-10 minutes,

allowing pushrods to be rotated with light finger

pressure. Extend pushrod covers and install cover clips.

Rotating engine before lifters have bled down may damage

pushrods and other components not covered under warranty.

E.

Rotate engine until both lifters for rear cylinder are at

lowest point on camshaft (TDC of compression stroke

for rear piston). Repeat steps R-T for rear pushrods.

4.

Pushrod Adjustment Procedure - for Tappets With HL

2

T

Kit Installed

A.

Bring piston to TDC on compression stroke in cylinder to

be adjusted. Normally both tappets will be at their

lowest point of travel.

B.

Extend pushrod adjustment, collapsing lifter until piston

assembly is in contact with HL

2

T spacer and pushrod is

tight. If tappets contain oil, as when pushrods are

readjusted after engine has been run, or if all oil was not

removed during HL

2

T installation, extend pushrod

adjustment until valve is open (about five additional

turns of adjusting screw). Allow 5 minutes for hydraulic

unit to bleed down. If pushrod can be turned with

fingers after bleeding down, lifter is not completely

collapsed, and this step must be repeated.

NOTE: Perform this operation on one cylinder at a time. Do not

turn engine until pushrod adjustment is complete.

Turning engine while valve is held off the seat could result in

valve to valve or valve to piston contact and serious valve

train damage.

C.

Loosen pushrod adjustment until pushrod can be

rotated with the fingers with slight drag. Pushrod

now has zero lash.

NOTES:

G Shortening pushrod adjuster an additional six flats or one

full turn from zero lash often results in quieter pushrod

operation. This provides additional travel for the

hydraulic piston assembly, which can improve the ability

of the hydraulic unit to maintain zero lash under normal

operating conditions.

G Harley-Davidson Twin Cam 88 lifters require HL

2

T Kit 33-

5339 for 1986 and later engines.

D.

Tighten lock nut and recheck pushrod adjustment to

insure that it is still correct.

E.

Follow the same procedure for all four push rods.

NOTES:

G After a few hundred miles it is a good idea to recheck

pushrod adjustment in a new engine as valve train may

tighten up due to gasket compression and valve seat wear.

G Upon initial start up after modification, HL

2

T equipped lifters

may be somewhat noisy for 10-20 miles. If lifters are still

noisy after 20 miles it is recommended that pushrods be

adjusted

1

⁄

2

turn looser.

CAUTION

CAUTION