Caution – S&S Cycle Gear Drive Cams for Harley-Davidson Twin Cam 88 Engines User Manual

Page 4

I.

Working gradually around edge of each sprocket,

carefully pry sprockets loose. Remove sprocket and

chain assembly.

J.

Remove chain guide. See Picture 4.

K.

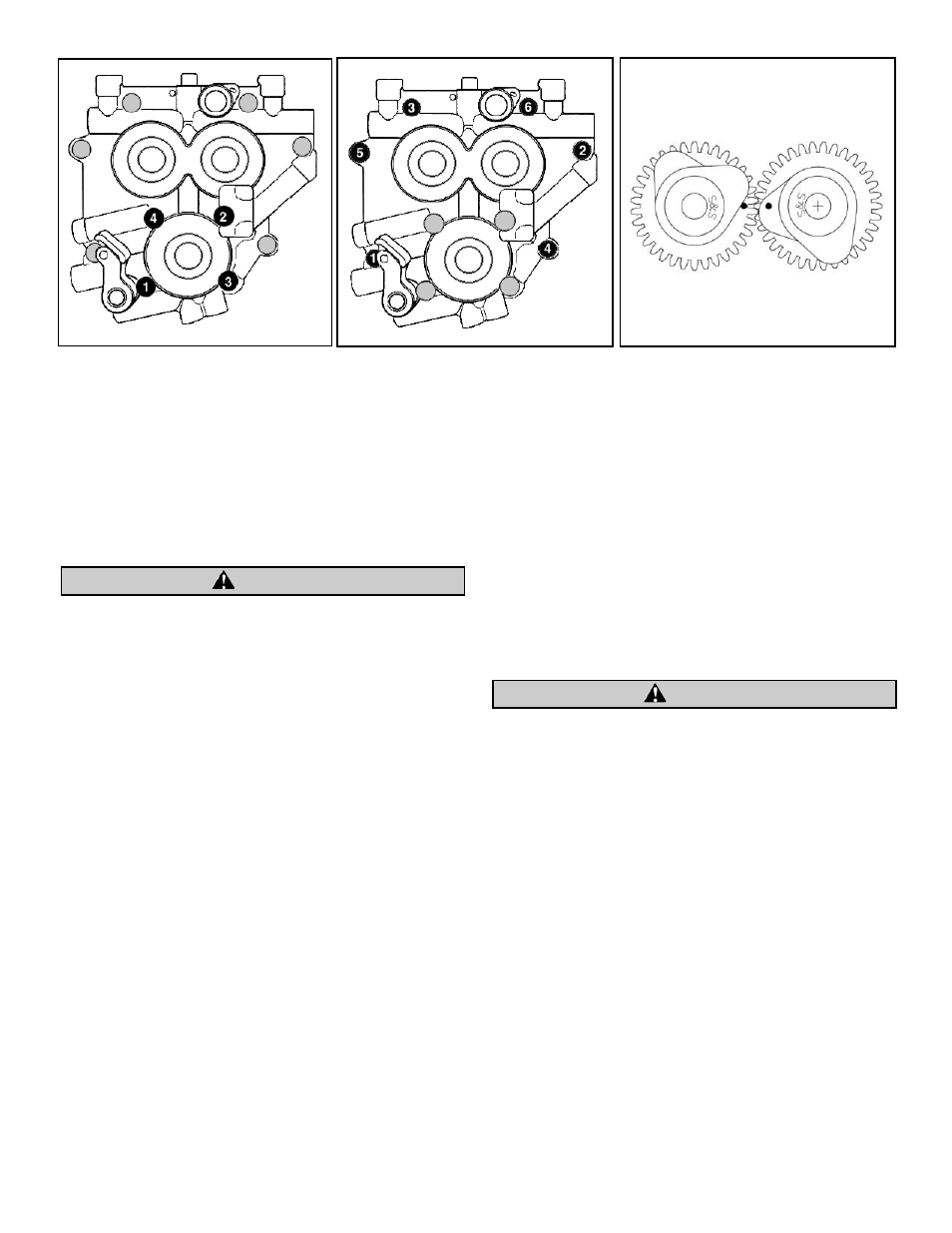

Following sequence shown, alternately loosen and

remove oil pump bolts. See Figure 1.

L.

Following sequence shown, alternately loosen and

remove cam support plate bolts. See Figure 2.

Failure to remove and install bolts according to correct procedure

may result in parts damage not covered under warranty.

M. Carefully remove cam support plate assembly from case.

All references to Harley-Davidson

®

part numbers is for

identification purposes only. We in no way are implying that

any of S&S

®

Cycle’s products are original equipment parts or

that they are equivalent to the corresponding Harley-

Davidson

®

part number shown.

NOTE: It is not necessary to remove oil pump from engine to

complete this installation unless grinding in gear case must be

performed for clearancing. If grinding is to be done all gear case

components must be removed and all holes taped off with duct

tape to avoid contamination of engine with chips.

N.

Use Harley-Davidson

®

cam chain tensioner unloader

H-D

®

#42313 to move tensioner away from secondary

cam chain. Secure tensioner by inserting second

retention pin through front of support plate.

O.

Remove bearing retainer screws and bearing retainer

from cam support plate.

P.

With cam support plate positioned securely in a

hydraulic press, use Harley-Davidson

®

camshaft

remover/installer H-D

®

#43644 to press both camshafts

and bearings from support plate simultaneously.

NOTES:

G Cam bearings may have a loose fit in cam support plate.

Camshaft and bearing assemblies may drop out when

beginning pressing procedure. Camshafts with roller style

bearings will be loose and drop out of support plate.

G The S&S Gear Drive Cams require that ball bearings be used

for both front and rear camshaft outer bearings. The roller

bearing used for the rear camshaft in some stock engines has

too much internal clearance. This allows center to center

distance of gears to vary, causing excessive gear noise. Since

the gear drive does not exert a large side load on the rear

camshaft, the higher load handling capacity of the roller

style bearing is not required.

Q. Use Harley-Davidson

®

cam chain tensioner unloader H-D

®

#42313 to remove retention pin from either tensioner.

Allow tensioner to completely relax. Remove retaining

ring and tensioner assembly from cam support plate.

Repeat this procedure for remaining tensioner.

2.

Install Gear Drive Cams

Check pinion shaft runout. Indicate end of pinion shaft at cam

support plate bushing surface and rotate engine; reading must

be .003” or less total indicated reading (TIR). If reading is greater

than .003” TIR the crankshaft must be repaired or replaced to

correct excess runout before installing gear drive cams. Failure to

correct excess runout may lead to engine damage not covered

under S&S warranty.

NOTE: Do not reuse cam bearings. If S&S Camshaft Installation Kit

33-5163 is not being used, new bearings should be obtained from

another source and installed with new camshafts. The S&S Gear

Drive Cams require that ball bearings be used for both front and

rear camshaft outer bearings.

A.

Apply assembly lube to outer races of cam bearings and

bearing bores in support plate. With cam support plate

positioned securely in a hydraulic press, use Harley-

Davidson

®

camshaft remover/installer H-D

®

#43644 to

install both bearings. See Picture 5.

NOTE: Check clearance between bearing retainer and woodruff

keys securing inner gears to cams. Remove material from

retainer, to provide .030" clearance between key and retainer.

See Picture 6.

B.

Align hole in bearing retainer with oil passage in

support plate. Install bearing retainer screws with a

drop of blue Loctite

®

threadlock 242 or 243 and

tighten screws to 20-30 in-lbs. torque.

4

Figure 1

Figure 2

Figure 3

CAUTION

CAUTION