Caution – S&S Cycle Gear Drive Cams for Harley-Davidson Twin Cam 88 Engines User Manual

Page 5

C.

Apply assembly lube to outer bearing surface of front

(shorter) camshaft and inner race of front bearing.

Support bearing by inner race and press camshaft all

the way into bearing. Install retaining ring on outer

end of front camshaft.

NOTE: Do not reuse retaining ring. If S&S Camshaft Installation

Kit 33-5163 is not being used, a new retaining ring be obtained

from another source and installed with new camshaft.

D.

Apply assembly lube to outer bearing surface of rear

(longer) camshaft and inner race of rear bearing.

Support bearing by inner race and with camshaft gear

timing marks aligned (See Figure 3), press camshaft all

the way into bearing.

All references to Harley-Davidson

®

part numbers is for

identification purposes only. We in no way are implying that any

of S&S

®

Cycle’s products are original equipment parts or that they

are equivalent to the corresponding H-D

®

part number shown.

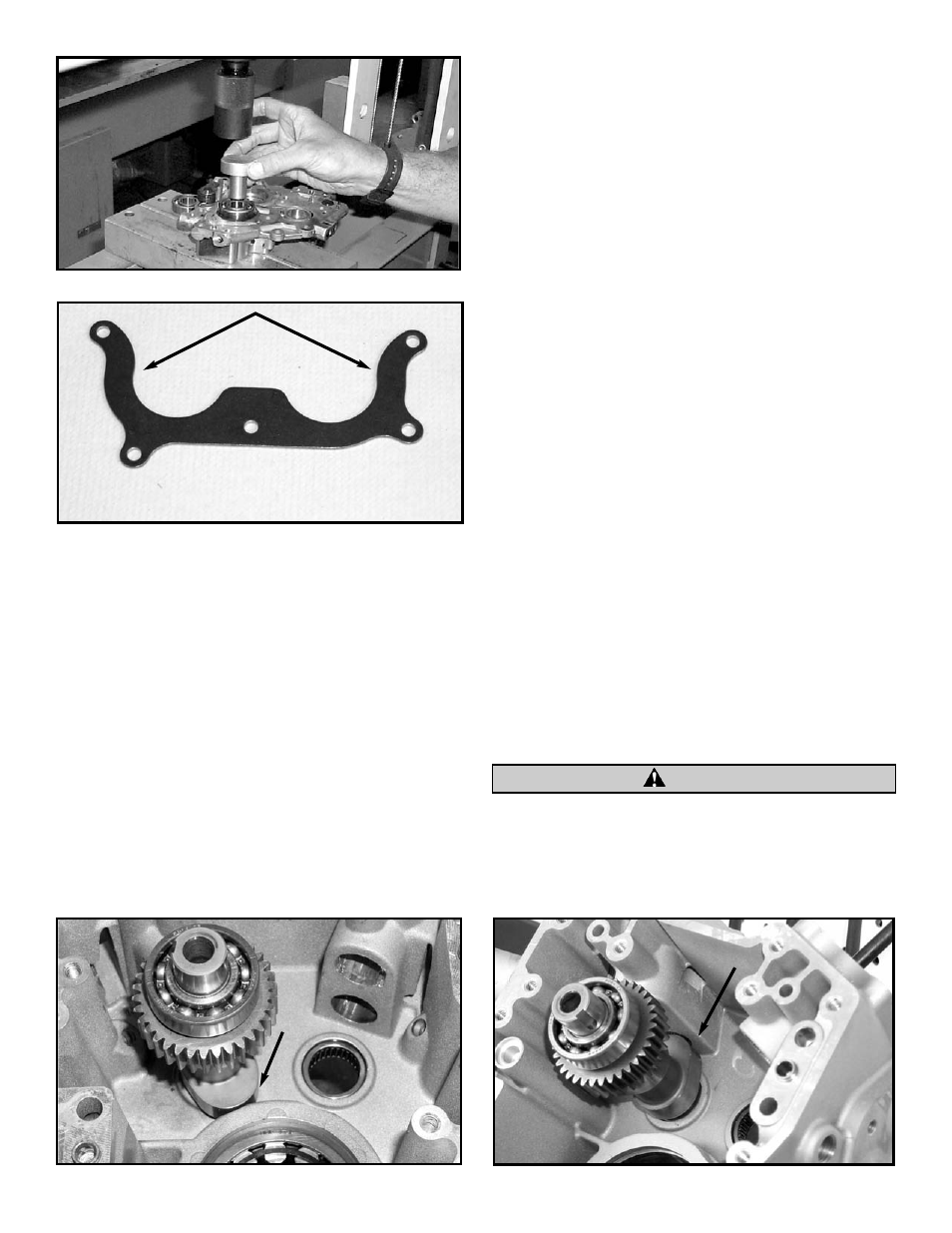

E.

When using 585G, 625G, or 640G camshafts (33-5168,

33-5170, or 33-5172) clearance between pinion bearing

boss and rear cam lobe must be checked. See Pictures

7 & 8. Remove just enough material to provide .030"

clearance between top of cam lobe and pinion bearing

boss when camshaft is rotated in inner needle bearing.

Also check clearance between all cam lobes and tappet

guide bosses. To avoid contamination of engine with

chips, we recommend that all holes in the gear case be

taped off with duct tape and that gear case be

thoroughly cleaned with parts cleaner or solvent after

clearancing is performed.

F.

Carefully remove camshaft needle bearings from

crankcase with Harley-Davidson

®

camshaft needle

bearing remover/installer H-D

®

#42325, and replace

them with new bearings provided in S&S Camshaft

Installation Kit 33-5163, or with bearings from

another source. Cam bearings must be Torrington

B148 full complement bearing or equivalent.

NOTE: Before reinstalling cam support plate, make sure oil

pump O-rings are in good condition and remain in place

during following procedure. Replace worn or damaged O-rings

if necessary.

G.

Apply a thin layer of assembly lube to cam journals, lobe

surfaces, and inner bearing surfaces. Align camshafts

with needle bearings and carefully slide support plate

over crankcase dowels.

NOTE: Support plate assembly should slide into place without

resistance. If resistance is encountered, determine cause and

correct problem before proceeding. Do not force support

plate into position!

H.

Loosely install support plate screws with a drop of

Loctite

®

threadlock 242 or 243 (blue). Alternately

tighten screws to 95 in-lbs. torque following sequence

shown. See Figure 2.

Support plate screws that pass through alignment dowels (See

positions 1 & 2 in Figure 2) can be easily stripped when

applying maximum 120 in-lbs. torque as recommended by

Harley-Davidson

®

.

5

Picture 5

Picture 6

Picture 7

Picture 8

If additional clearance is required, remove

material from areas indicated to provide

.030" clearance between key and retainer.

CAUTION