Calibrating infrared methane sensors – RKI Instruments Eagle 1 Manual User Manual

Page 77

Eagle Instruction Manual

Appendix E: Infrared Methane Sensors • 70

these models, the infrared methane sensor is wired to the EC4 socket

on the analog PCB and the gas reading is displayed in channel 1. This

sensor is also capable of measuring in the PPM range.

Eagles with an infrared methane sensor that has a 0 to 100% Volume

CH

4

range may also include the standard combustible gas sensor.

Table 14 lists the sensor configuration for Eagles that include this

sensor. Not all channels may be active in your Eagle.

Calibrating Infrared Methane Sensors

Recommended calibration frequency for the infrared methane sensor

is once every 3 months. Enter Calibration mode and calibrate the

infrared methane sensor using the same procedure as the standard

combustible gas sensor (see “Calibration” on page 42).

NOTE:

The 0 to 100% Volume CH

4

version of the infrared methane

sensor requires the use of a sample bag due to the type of

calibration cylinder used. See Table 15 on page 71 for ordering

information.

Adjusting the Sensor Controls

CAUTION:

Only perform the following steps if you are unable to set the

correct calibration reading with the AIR/

▲

and SHIFT/

▼

buttons.

1. Use the AIR/▲ and SHIFT/▼ buttons to set the reading to the

middle of the range in which you can currently adjust the reading.

For example, if you can set the reading from a minimum of 10%

LEL to a maximum of 40% LEL, set the display to 25% LEL.

2. Unscrew the two large screws on the top of the case, then carefully

lift the top of the case and lay it aside.

3. Locate the infrared methane sensor in the front half of the bottom

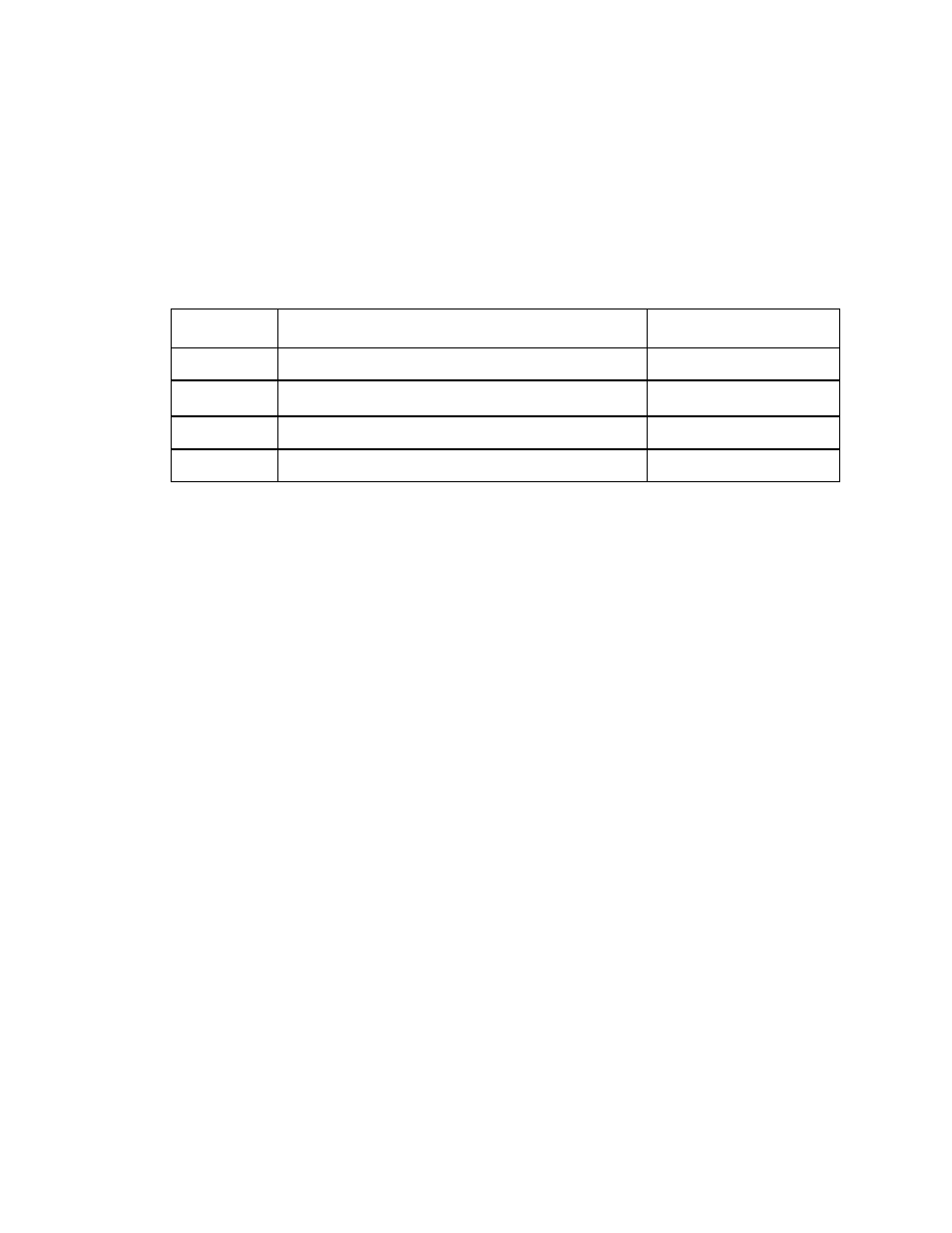

Table 14: Sensor Configuration for Infrared Methane Sensors

(0 to 100% Volume)

Channel

Sensor

Analog PCB Socket

1

Standard combustible gas (0 to 100% LEL)

COMB

2

Infrared methane (0 to 100% Vol. CH

4

)

EC4

3

Oxygen

CN2

4

Toxic gas or infrared carbon dioxide

EC1, EC2, or EC3