Working instructions, Sieving aids sieving material quantities, Overview table – Retsch AS 300 User Manual

Page 19: Sieving material quantities, Sieving aids

07/02/2012

Retsch GmbH

19

Working instructions

Sieving aids

When dealing with material that is difficult to separate, we rec-

ommend the additional use of sieving aids in the individual sieve

fractions. Depending on the width of the sieve meshing and the

preselected vibration intensity, pearls made of agate, rubber, por-

celain or nylon bristles and Vulkollan cubes may be used. Also re-

fer to the table below.

Ensure that the fabric of the sieve is not overstretched by over-

loading with sieving aids as this would have a detrimental effect

on the precision of your analytical sieve.

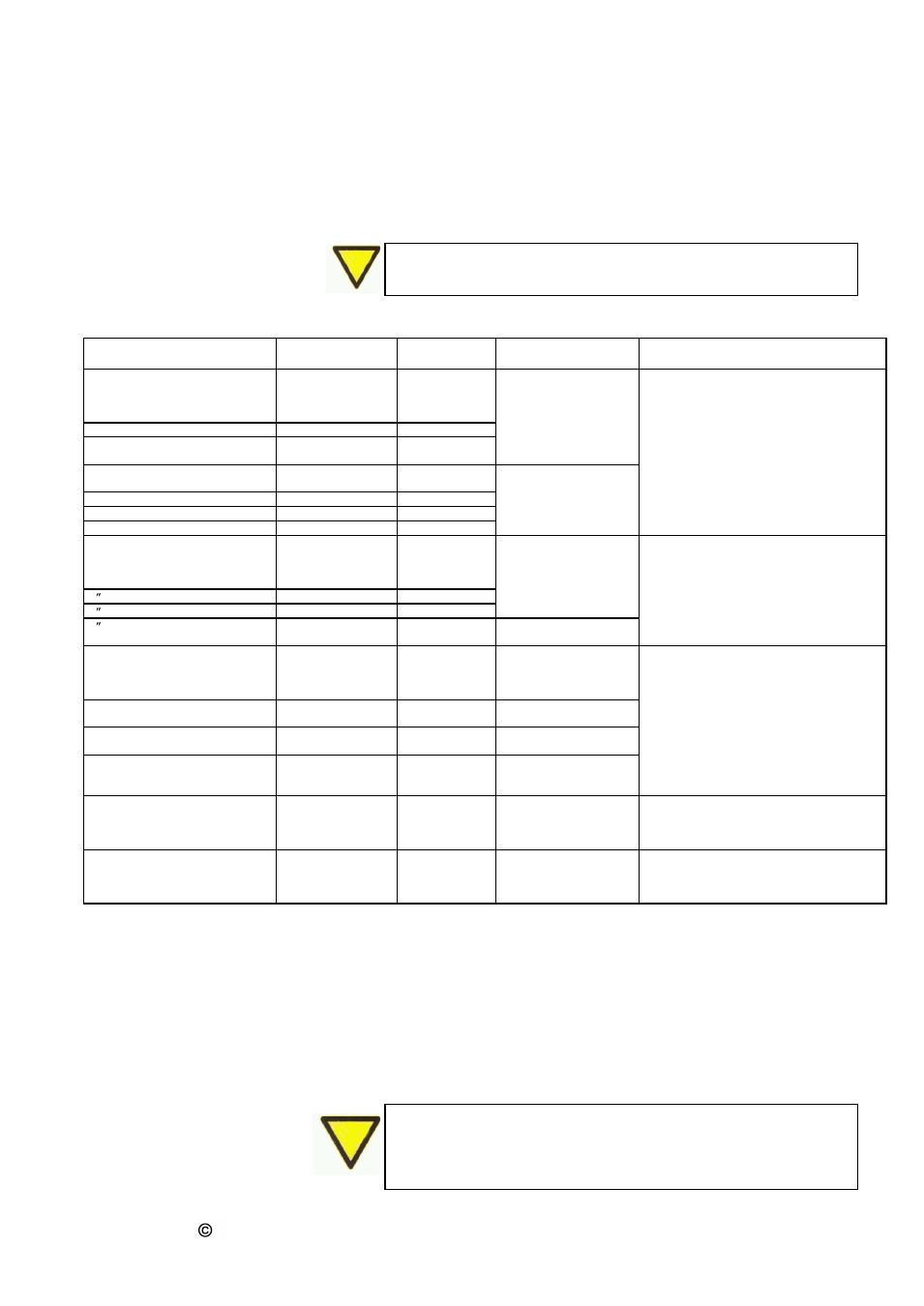

Overview table

Sieving aids

Quantity per

sieve or charge

Supplier

Area of use

Caution !!

Rubber pearls

5 pcs, Ø20 mm

RETSCH, Haan

Materials to be screened

are fine, dry,

difficult to separate and

throw sieves are used

When using mechanical sieving aids, there

is the danger that soft materials can disin-

tegrate and fine sieve fabrics can be dam-

aged!

Agate pearls

10 pcs, Ø10 mm

RETSCH, Haan

Hard porcelain pearls

approx. 10gr., Ø2

mm

RETSCH, Haan

Vulkollan cubes

5 pcs, 12x12

RETSCH, Haan

Planetary sieving ma-

chines

Bristles

3 pcs

RETSCH, Haan

Plastic rings

3 pcs, various Ø

Brushes

Manual sieving

Highly dispersed silicic acids

0.5 to 2%

Degussa, Ffm

Materials to be screened

are fine, sticky, fatty

and electrostatically

charged

Check applicability and compatibility before

adding!

- - Aluminium oxide

0.5 to 1%

Degussa, Ffm

- - active carbon

- - talcum

Latex and rubber pow-

der

Remove grease

Materials to be screened

are very fatty

The granularity of the material to be

screened may not be altered by the solvent

used to remove grease or by the tempera-

ture and air used in drying.

Dry

Materials to be screened

are very wet or damp

Guide dry, warm air through the

sieve set

Hygroscopic materials to

be screened

Cleanse with steam

Materials to be screened

are coarse and electro-

statically charged

First sieve of the fine sieve then

the coarse sieve

If contamination from

other mechanical aids,

such as rubber pearls, is

to be avoided

The coarse material functions like a me-

chanical sieving aid (pearls) on the fine

sieves.

Intermittent sieving

RETSCH, Haan

Materials to be screened

are fine, stick easily, or

only fall through the

mesh with difficulty

Intermittent switching is built into the

majority of throw sieves and can be

switched on, if required.

Sieving material quantities

The sieve stack required for sieve analyses is composed of ana-

lytical sieves arranged one above the other, with progressively

larger holes towards the top, plus the base pan.

To ensure fast separation with exact results, the quantity of the

material to be screened should be adapted to the sieve diameter

and the nominal size of the openings.

The relevant standards on sieve analysis state guideline values in

this context.

In the case of sieving processes with only 1 to 3 sieves, we rec-

ommend the use of short threaded rods ( available as accesso-

ries ).

Overly long, protruding rods interfere with the material to be

screened due to their inherent vibration characteristics.