Distribution of the sieved product – Retsch AS 200 User Manual

Page 21

31.07.2012

Retsch GmbH

21

Distribution of the sieved product

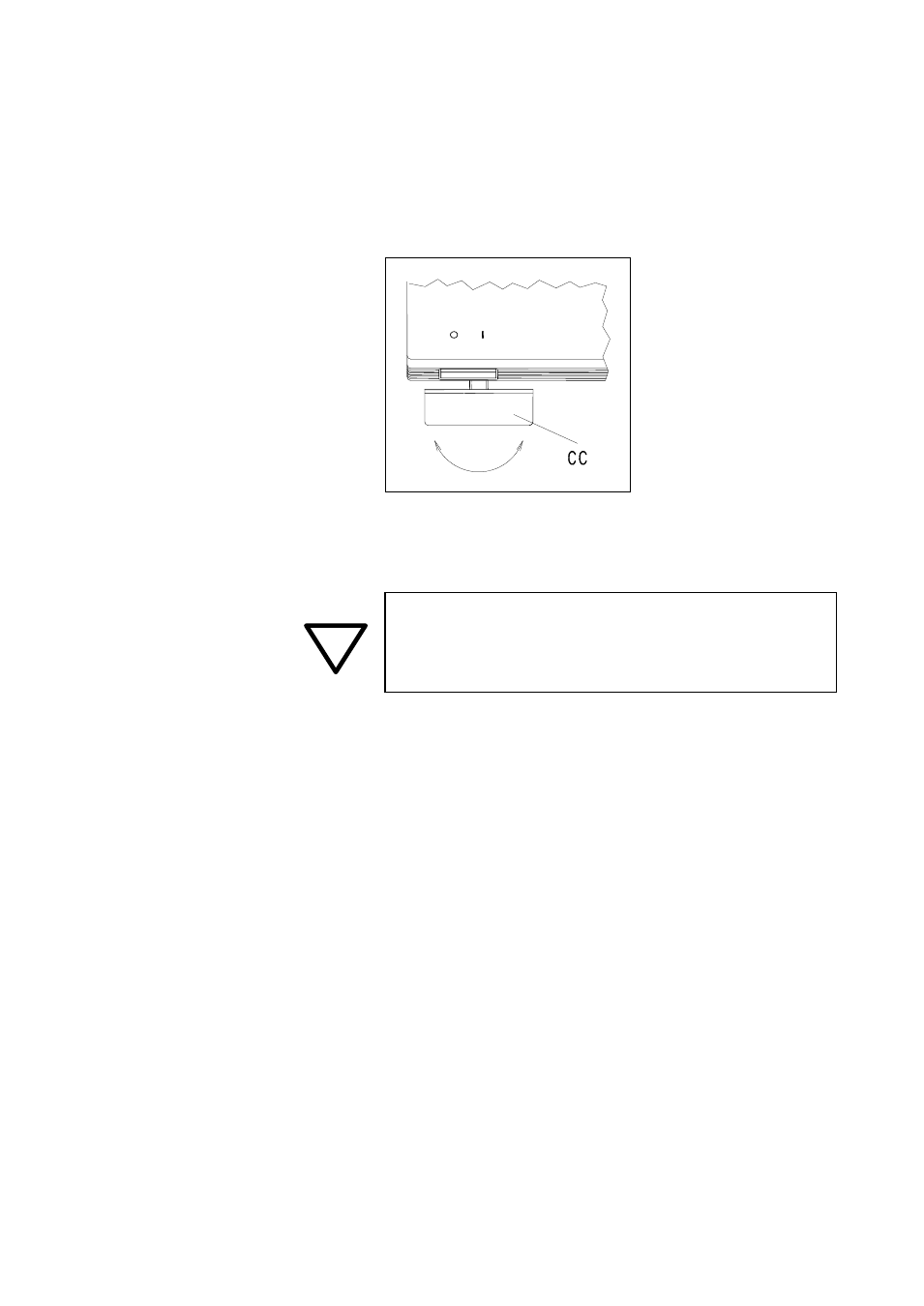

Even in procedures with only a single sieve, the AS200

will provide largely uniform distribution of the product

across the sieve screen. Depending on the vibration

height which is selected, the product will be moved

slowly in a circular direction.

Proper leveling of the AS200 is an important factor here.

Leveling can be corrected by screwing the feet CC in or

out as required. Fig. 19

Fig. 19

It is not necessary to lock the feet in position once

adjustment has been made.

When carrying out sieving processes with only one to

three sieves, we recommend using the short rods.

Overly long rods, extending above the stack, will interfere

with distribution of the product due to their intrinsic reso-

nance.

- BB 50 (41 pages)

- BB 100 (24 pages)

- BB 200 (24 pages)

- BB 300 (24 pages)

- Cryomill (68 pages)

- CryoMill Autofill 50l (28 pages)

- DM 200 (20 pages)

- DM 400 (60 pages)

- Emax (67 pages)

- GM 200 (44 pages)

- GM 300 (44 pages)

- MM 200 (32 pages)

- MM 400 (32 pages)

- PM 100 (44 pages)

- PM 400 (36 pages)

- PM GrindControl (48 pages)

- RM 200 (36 pages)

- RS 200 (32 pages)

- SK 100 (24 pages)

- SM 100 (48 pages)

- SM 200 (48 pages)

- SM 300 (44 pages)

- Cyclone - SM 300 (20 pages)

- SR 200 (24 pages)

- SR 300 (24 pages)

- TWISTER (44 pages)

- ZM 200 (32 pages)

- AS 200 jet - Automatic Vacuum Regulation (6 pages)

- AS 200 control - natural frequency (32 pages)

- AS 200 jet (56 pages)

- AS 200 jet (48 pages)

- AS 200 tap 30.025.0001 (28 pages)

- AS 200 tap 30.025.1001 (28 pages)

- AS 300 (32 pages)

- AS 400 (32 pages)

- AS 400 (28 pages)

- AS 450 basic (40 pages)

- AS 450 basic (44 pages)

- AS 450 control (52 pages)

- DR 100 (40 pages)

- DR 100 (28 pages)

- PP 25 (32 pages)

- PP 40 (28 pages)

- PT 100 (36 pages)