Milling cup identification, Milling cup labelling by the customer, Cleaning the milling cups – Retsch PM 400 User Manual

Page 20: Drying the milling cups, Tips for ultra-fine milling

08.02.2012

Retsch GmbH

20

Doc. Nr. GB 98.535.9999

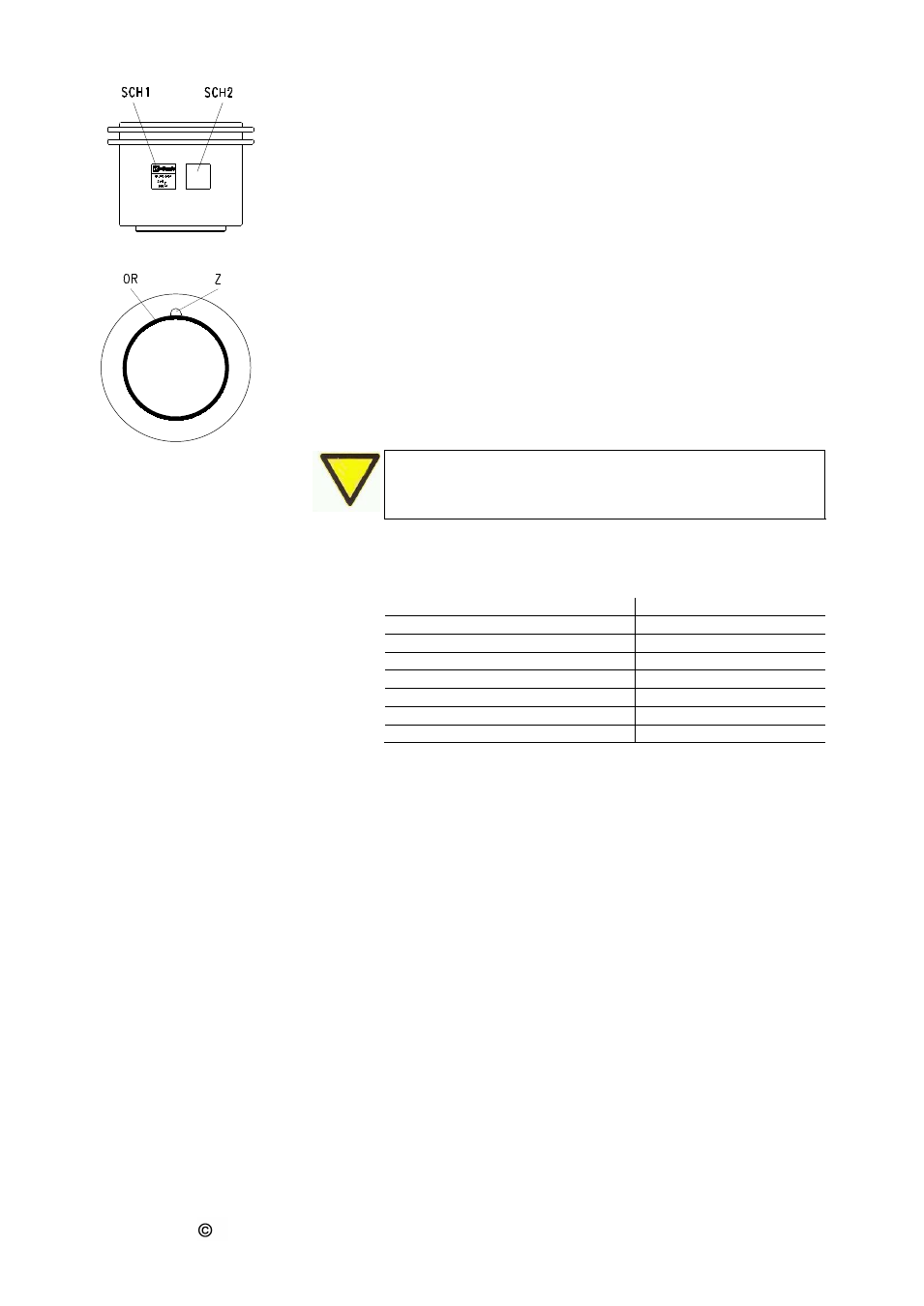

Milling cup identification

All milling cups of type „C“ are easy to identify through the

labelling area SCH1 which shows the article no. and

material.

Milling cup labelling by the customer

In addition to the above mentioned labelling area you can

stick one of the labels supplied with the machine or

available as accessories on the area SCH2 marked on the

milling cup – for labelling e.g. milling cup contents etc.

The label is heat resistant up to 150°C and your inscription

can be cleaned with e.g. alcohol, petrol or acetone.

Cleaning the milling cups

For cleaning the milling cups the O-ring on the groove Z on

the underside of the lid can be easily prised off.

Milling cups, including also those with stuck-in ceramic

inserts, can be cleaned with alcohol, petrol or normal

domestic detergents.

Do not subject milling cups with ceramic inserts to sudden

temperature differences when rinsing.

The ceramic inserts can crack through sudden

temperature differences.

Drying the milling cups

After cleaning the milling cups can be dried at any time in a

drying oven at the temperatures given below.

Milling cup material

Temperature

Special steel

up to 200°C

Stainless steel

up to 200°C

Tungsten carbide

up to 150°C

Sintered corundum

up to 120°C

Agate

up to 120°C

Zirconium oxide

up to 120°C

Silicon nitride

up to 120°C

Tips for ultra-fine milling

In many cases high finenesses can be achieved only by wet

milling.

In dry milling processes an improved fineness of milling can be

achieved by the addition of a few drops of stearic or acetic acid,

and use of milling balls with a diameter < 10 mm and a filling

level of 70-80% of the milling cup volume.