Retsch PM 400 User Manual

Page 15

08.02.2012

Retsch GmbH

15

Doc. Nr. GB 98.535.9999

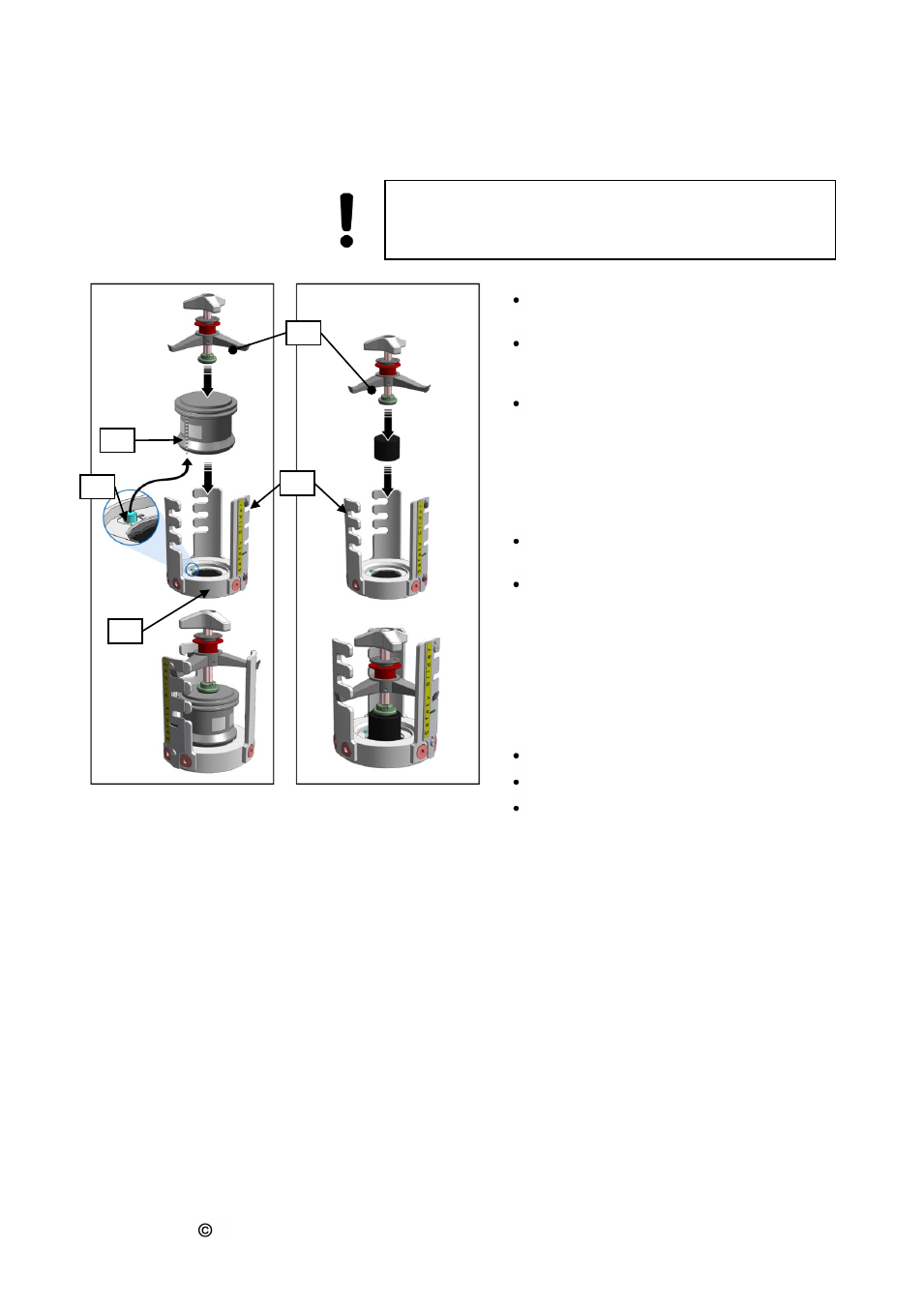

When grinding with 2 grinding jars, the two must be placed

opposite each other. Each of the two unoccupied grinding

stations must be secured with a clamping pin and a spider

(see illustration). The safety slider function will otherwise

prevent the device from starting.

A high level of vibration by the mill indicates wrong taring or

incorrectly clamped grinding jars!

If unevenly loaded, the PM400 can generate

undesirable vibrations and noises! Turn the mill off

immediately and check the jars’ positioning and gross

weight!

If necessary, clean the grinding jar

turntable 1 and torsion lock pin 2.

Turn the grinding jar label 3 to the same

side as the torsion lock pin, where the

grinding jar’s borehole is.

Insert the grinding jar into the grinding

jar holder.

Pay attention to the torsion lock when using

250-ml and 500-ml grinding jars. The

borehole in the bottom of the grinding jar into

which the torsion lock pin 2 fits is on the side

of the labelling panels 3.

Insert the spider 4 into the three brackets

5.

When using two grinding jars, insert a

clamping pin and the spider into each of

the two opposite unoccupied grinding

stations.

Inserting and clamping the spider presses the

safety slider 6 upwards and activates it. Once

the mill has been started, the PM100 checks

this safety function for up to approx. 15

seconds long. If you

have not clamped the spider,

not inserted any spider or

the grinding jar is missing,

the PM100 will stop the starting procedure and

emit the error message F10.

1

2

3

4

5