Working instructions, General, The milling process – Retsch MM 200 User Manual

Page 22: Quantities of milling material and grain sizes

5/21/2012

22

Retsch GmbH

Working instructions

Target group: operators

General

The MM 200 is an ultramodern, high performance product

from Retsch GmbH.

Owing to the large selection of accessories the laboratory

oscillation mill, type MM 200, is a machine with many

different application possibilities, mainly in the chemical and

pharmaceutical sectors, in mineralogical and biological

applications etc, as well as in industrial laboratories and in

research.

The milling process

Clamp the machine filled with material to be milled, together with

the milling ball(s) in the milling cup holder as described.

Close the hood.

Set the milling parameters.

Start the MM 200.

Do not open the hood during the milling process.

Although the milling cups are brought to a standstill immediately

by the built-in brake, the milling process can no longer be

continued with the remaining running time.

The MM 200 must be restarted and the initial parameters are then

again available.

In order to guarantee quiet running of the MM 200 we recommend

that milling cups with the same mass as far as possible are

clamped in both milling positions.

Do not open the plexiglass hood during the milling process.

Although the milling cups are brought to a standstill immediately

by the built-in brake, the milling process can no longer be

continued with the remaining running time.

The MM 200 must be restarted and the initial parameters are then

again available.

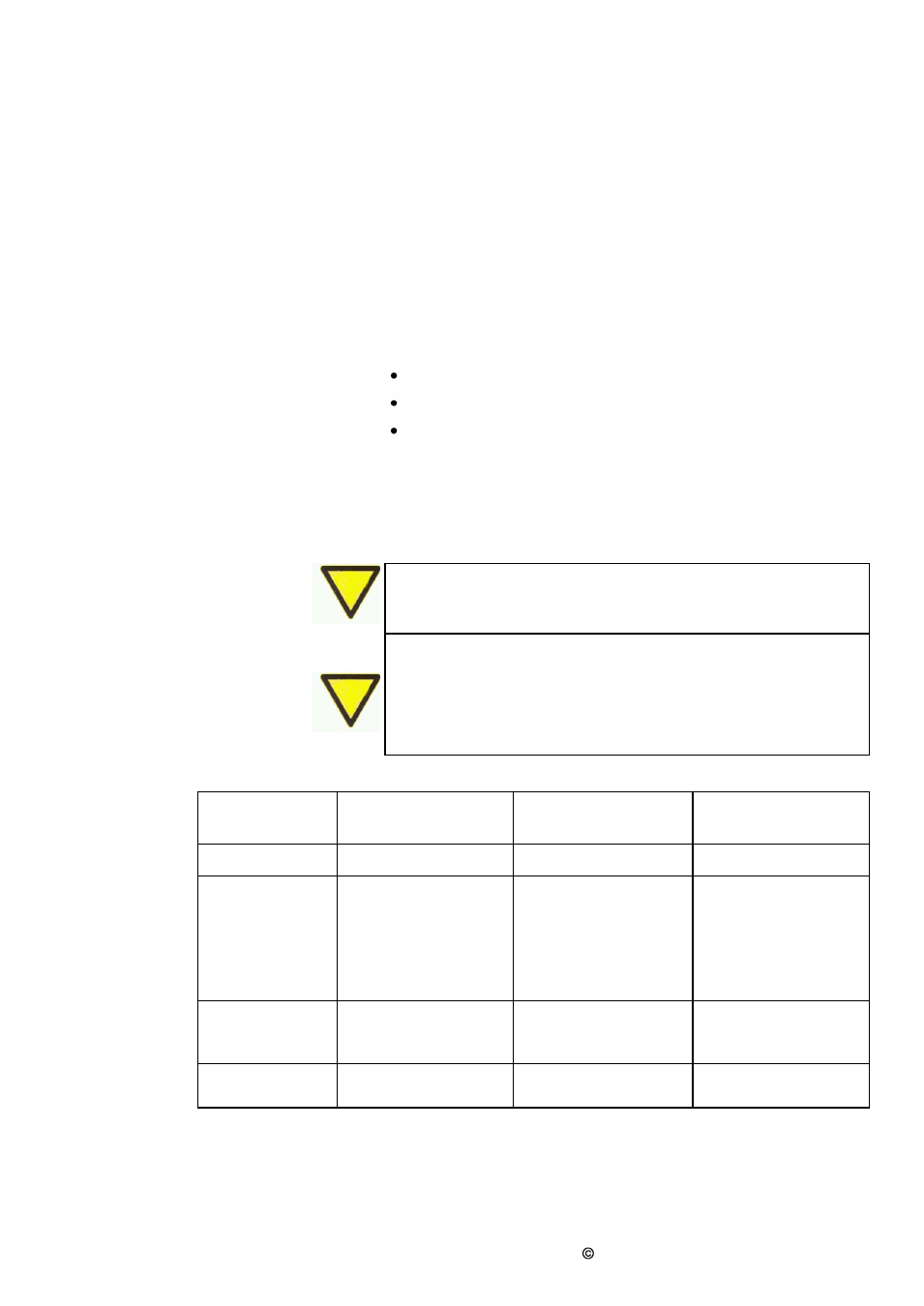

Quantities of milling material and grain sizes

Milling cup

volume in ml

Milling material

quantity in ml

min - max

Ball filling

optional

Number dia. in mm

max. charging grain

size in mm

25

4 - 10

1

15

6

10

2 – 4

2

1

2

1

12

12

9

9

4

5

0,5 – 2

2

1

7

7

2

1.5

0.2 – 0.5

2

1

5

5

1