Working instructions – Retsch BB 100 User Manual

Page 15

2/7/2012

Retsch GmbH

15

Working instructions

Target group: Laboratory technicians

General

The BB 100 is a rugged, floor-mounted unit which is used

primarily for preliminary crushing in preparation for final size

reduction.

Its continuous operating concept also makes the BB 100

suitable for integration into fully automatic and semi-automatic

processing lines.

The performance data, throughput rates and ultimate fineness

will depend on the fracture properties and hardness of the

product and on the gap width which is selected.

Grain size of feedstock product

The maximum grain size is determined by the size of the fill

hopper opening; in the BB 100 this is a maximum of 50 mm.

Properties of the product being crushed

Every hard and brittle product, exhibiting a hardness of greater

than 3 on the Mohs scale, can as a rule, be reduced with the BB

100.

Wet and oily product and that with a hardness index below 3

(Mohs scale) tend to be compressed and clump in the crushing

chamber, this being due to the pressure exerted by the breaker

jaws. It is for this reason that pre-crushing such material is

hardly possible.

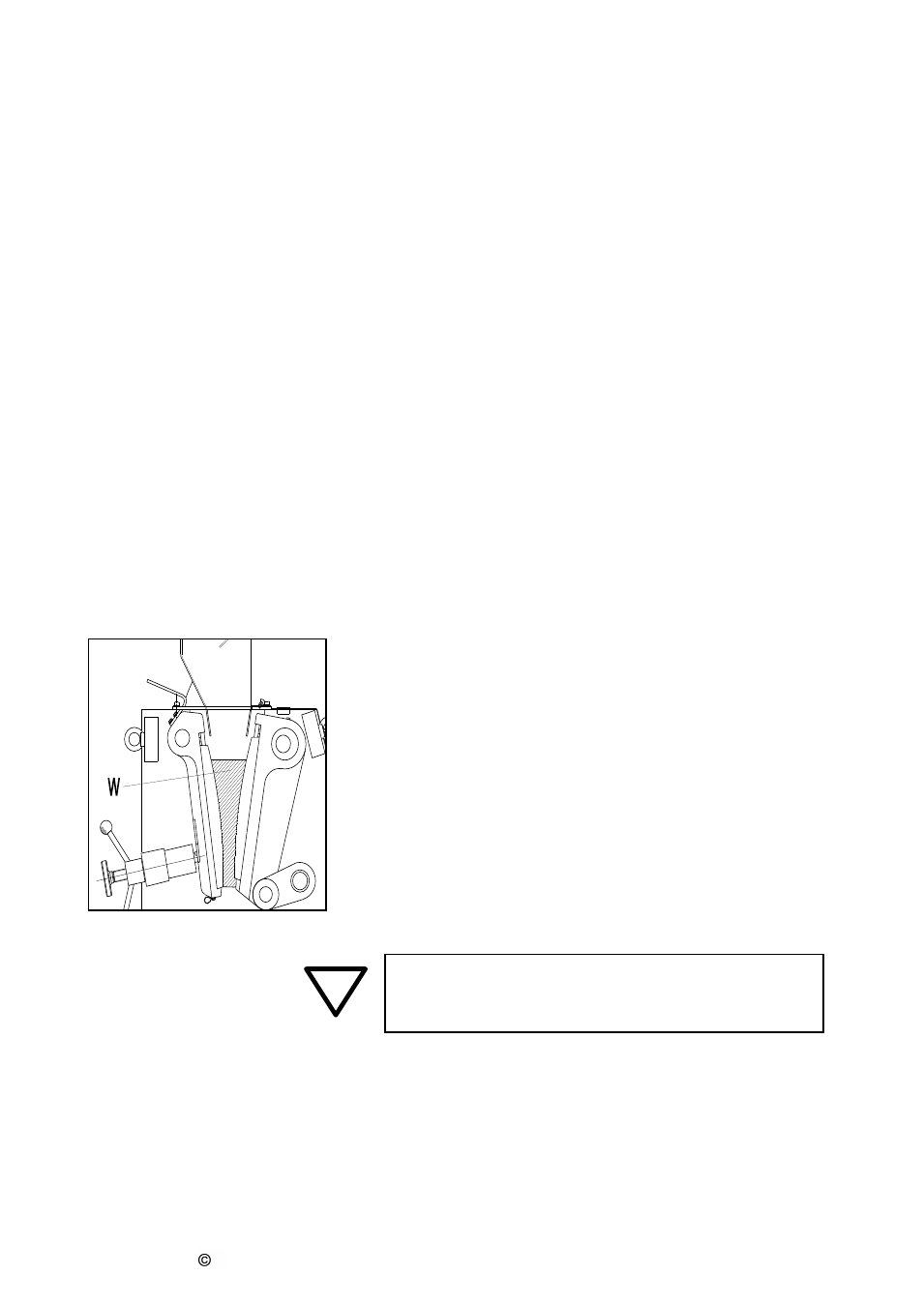

Fig. 6

Fill volume

If the crushing chamber W is filled with more than

2/3

=300ml,

then the guide plates of the fill hopper could be damaged and the

moving breaker would force the product into the crusher

housing, behind the breaker arm. Fig. 6

The fill level will also influence the proportion of fine material

in the product or specimen after preliminary crushing; the fuller

the crushing chamber, the greater the share of fines.

If the crushing chamber W is filled with more than

2/3

=300ml,

then the fill hopper guide plates could be damaged; the moving

breaker arm would force product behind the breaker arm and

into the crusher housing.